Production method of turbid type white beer with high yeast survival rate

A technology for turbid white beer and a production method, applied in the field of beer brewing, can solve the problems of no yeast activity or low yeast activity, and achieve the effects of long survival rate, reduced ester aroma and high alcohol taste, and maintaining yeast activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Ingredients

[0020] 45% Pale Wheat Malt, 55% Pale Barley Malt.

[0021] (2) Saccharification

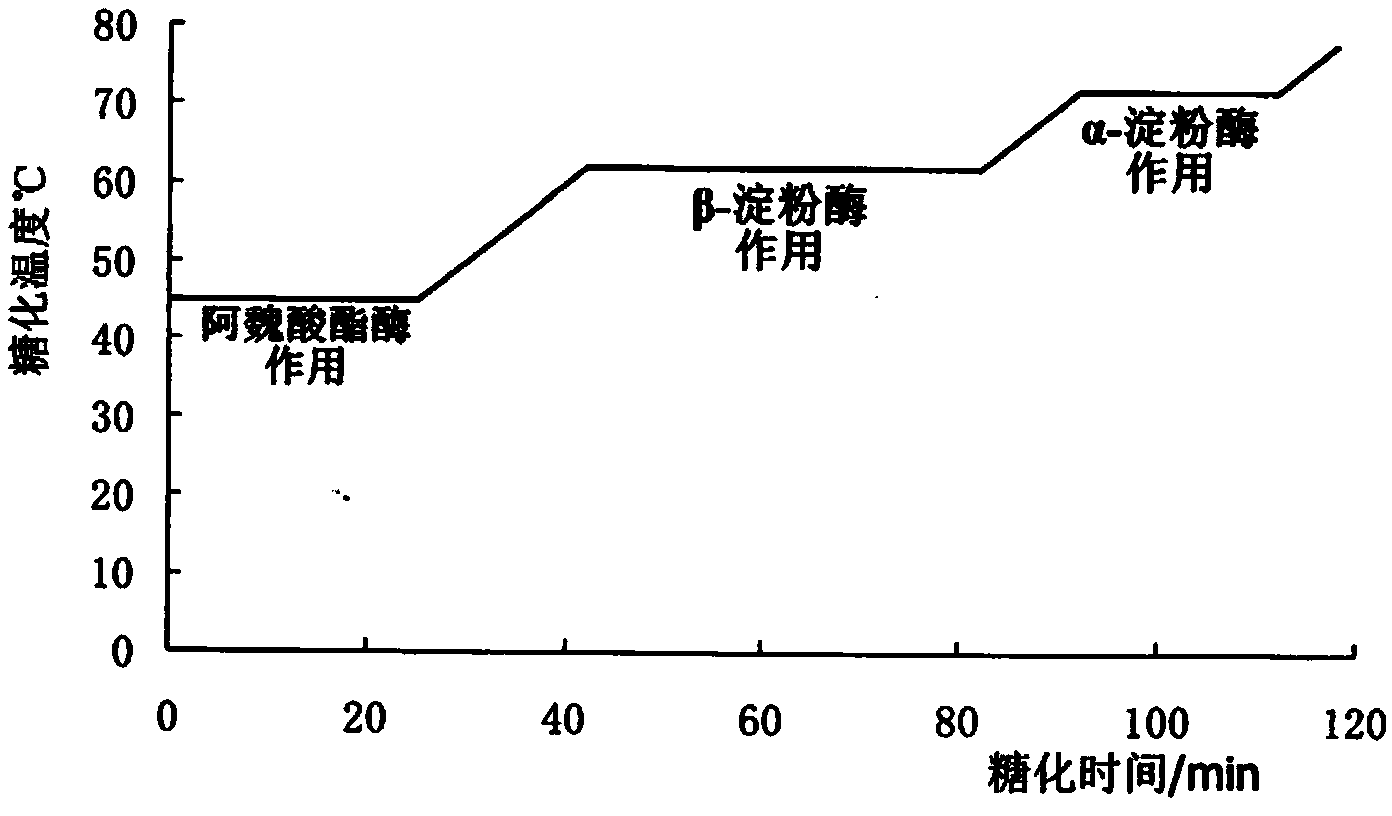

[0022] After the malt is crushed, it enters the saccharification pot, and the feeding water is 3.26 times the weight of the malt. Food-grade lactic acid is used to adjust the pH to 5.7-5.8. The saccharification temperature is controlled as follows: figure 1 As shown in the curve, control the temperature and time according to the curve. First, keep it warm at 45°C for 30 minutes to fully dissolve the protein and let the ferulic esterase act to dissolve ferulic acid; ; Then raise the temperature to 72°C and keep it warm for 20 minutes to make the α-amylase act. After the saccharification is completed, heat up to 80°C and introduce it into the filter tank for filtration. The filtrate is introduced into the boiling pot. The boiling time is 90 minutes. At the beginning of the wort boiling, add 90 type granule hops. Lactic acid adjusts the pH of the wort to 5.2-5.4, and the ...

Embodiment 2

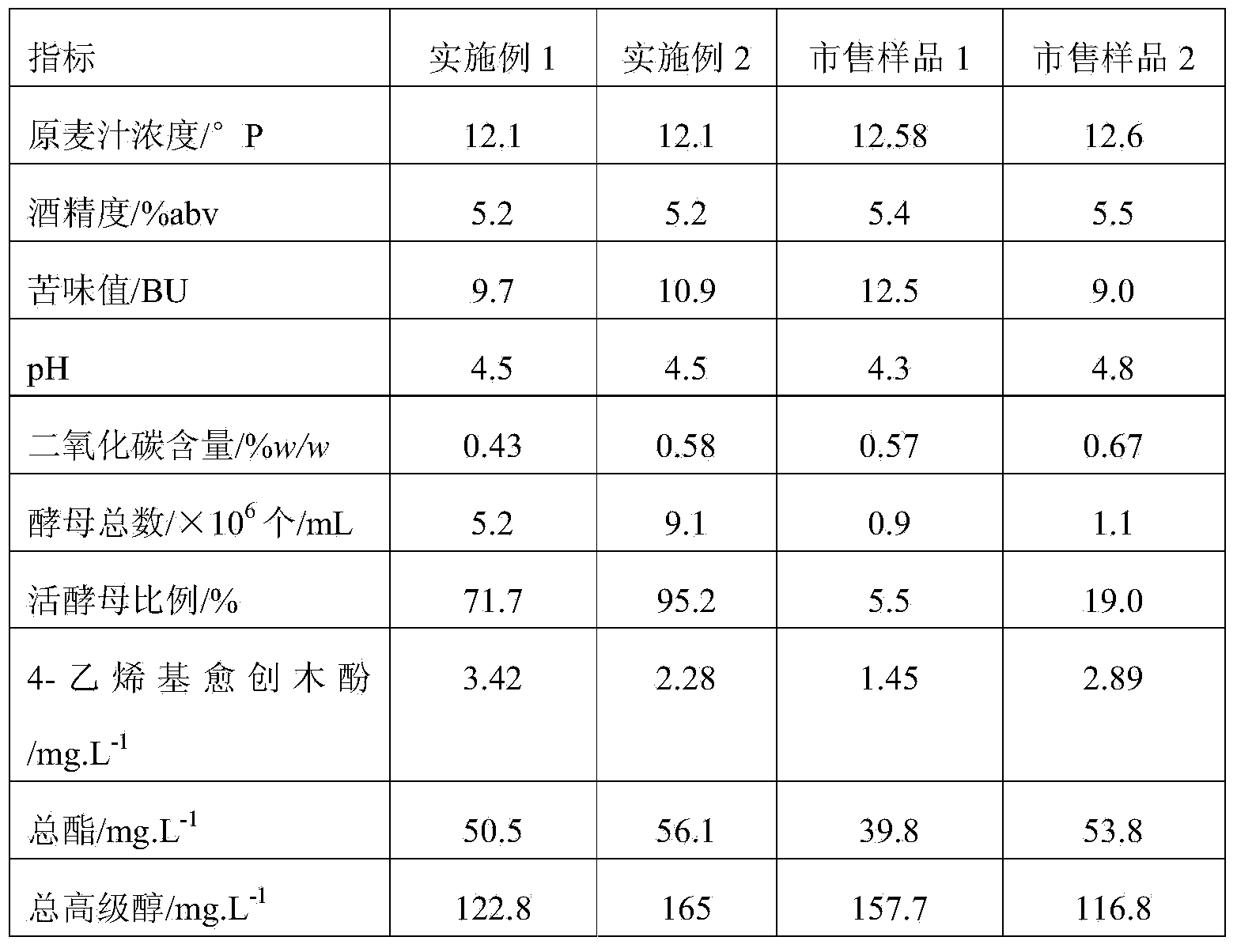

[0027] The basic process operation of batching, saccharification and fermentation is the same as that of Example 1, wherein the temperature of wort entering the tank is 15-16°C, and the preset fermentation temperature is 18°C.

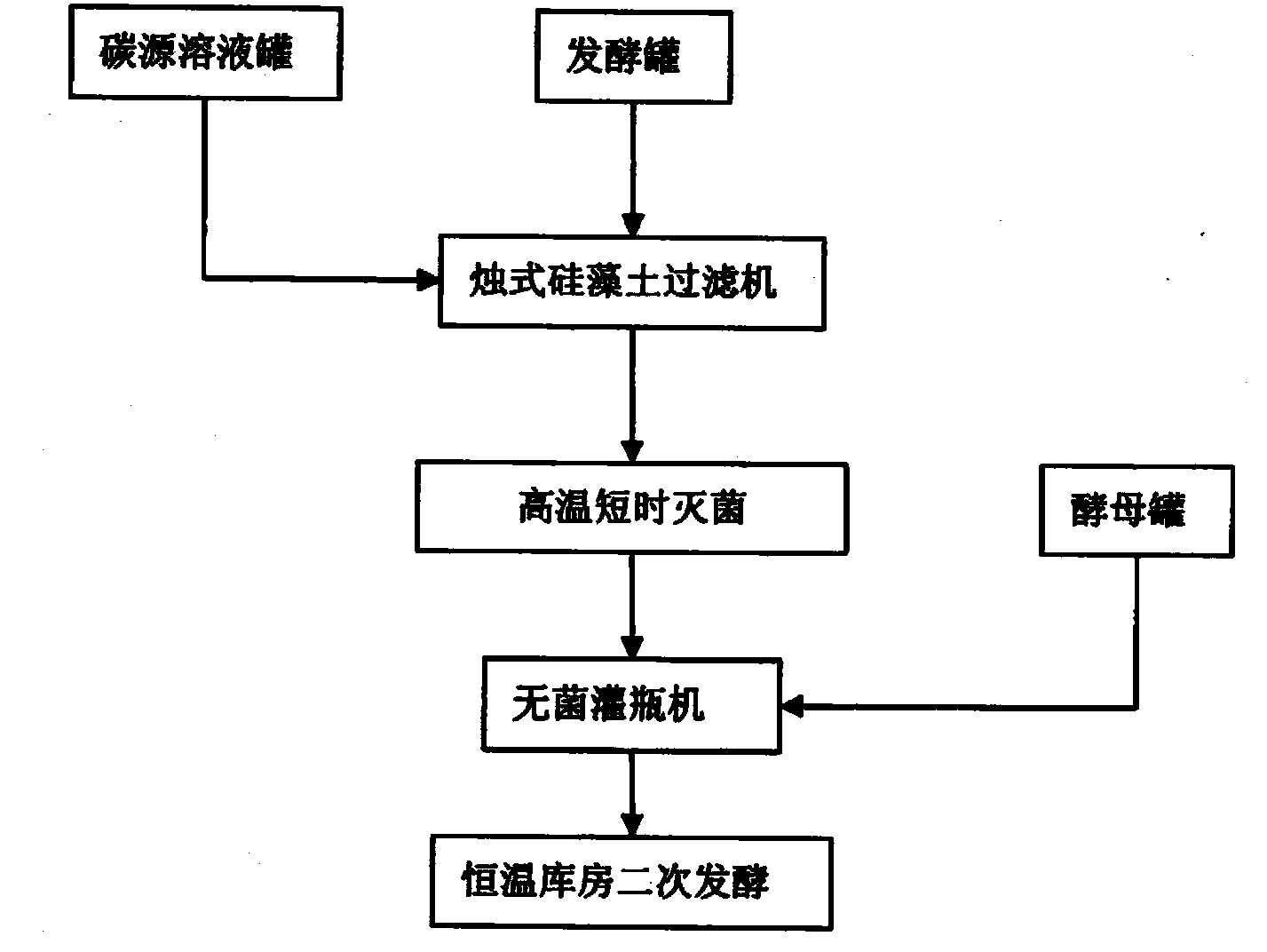

[0028] Cool the fermentation broth to 0°C for reference figure 2 The technological process carries out the secondary fermentation operation; wherein 12°P wort is used as the carbon source solution for the secondary fermentation, the fermentable sugar content in the soluble solids of the wort is 77%, the carbon dioxide content of the base wine is 0.30%, and the carbon dioxide in the finished wine is expected to The content is 0.60%, that is, the carbon dioxide content needs to be increased by 0.30% after the secondary fermentation, and it is substituted into the empirical formula y=0.4363x 1.1754 , it is calculated that fermentable sugar y=0.727g needs to be added to every 100mL finished wine, the corresponding wort solids need to be added 0.944g, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com