Waste and old tyre truss

A waste tire and truss technology, which is applied to truss structures, trusses, joists, etc., can solve the problems of not making full use of the elasticity and support of waste tires, not being environmentally friendly, energy saving, efficient, low cost, and unfavorable for popularization and use. , to achieve the effect of simple and effective recycling methods, simple structure, and reduced processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

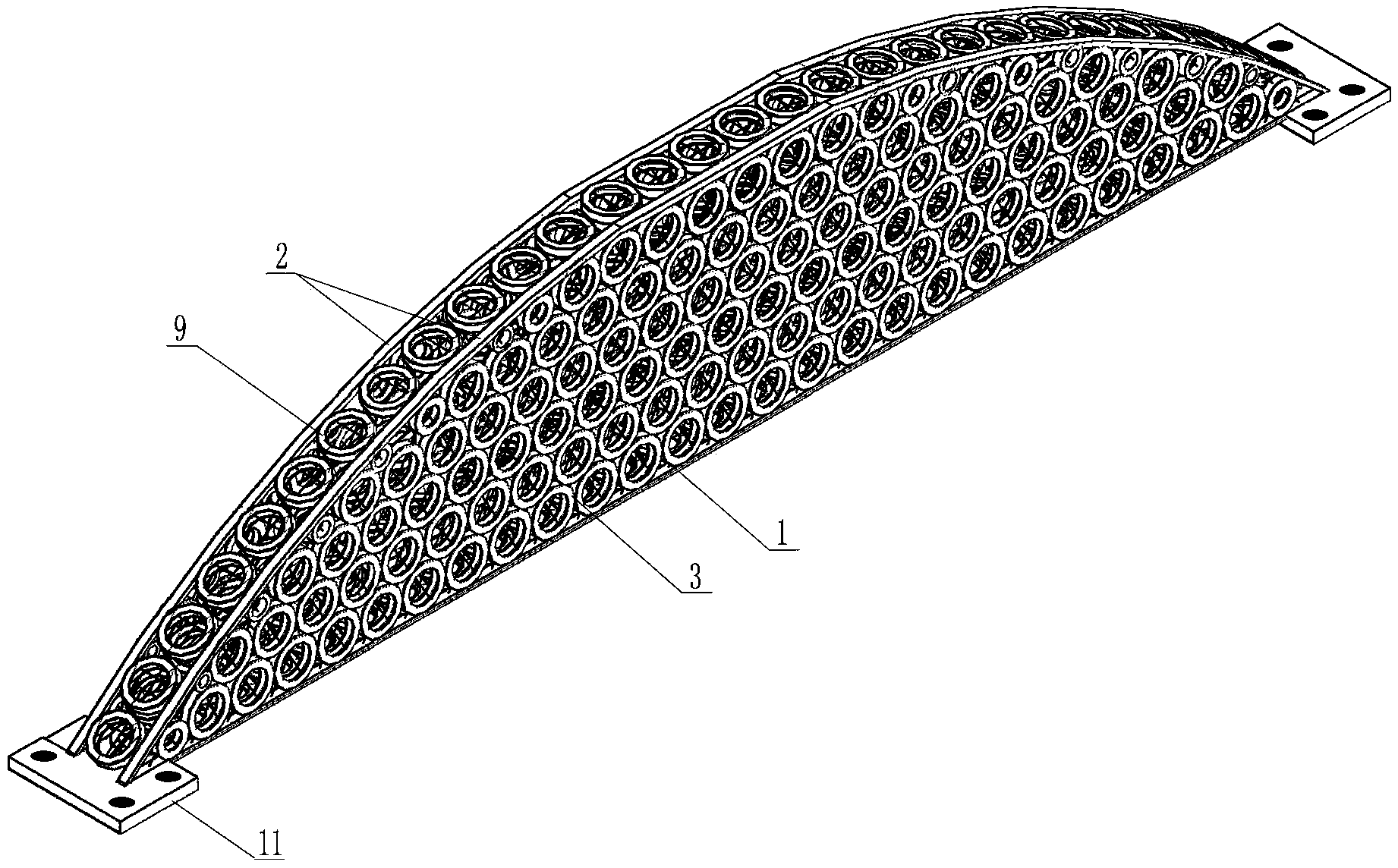

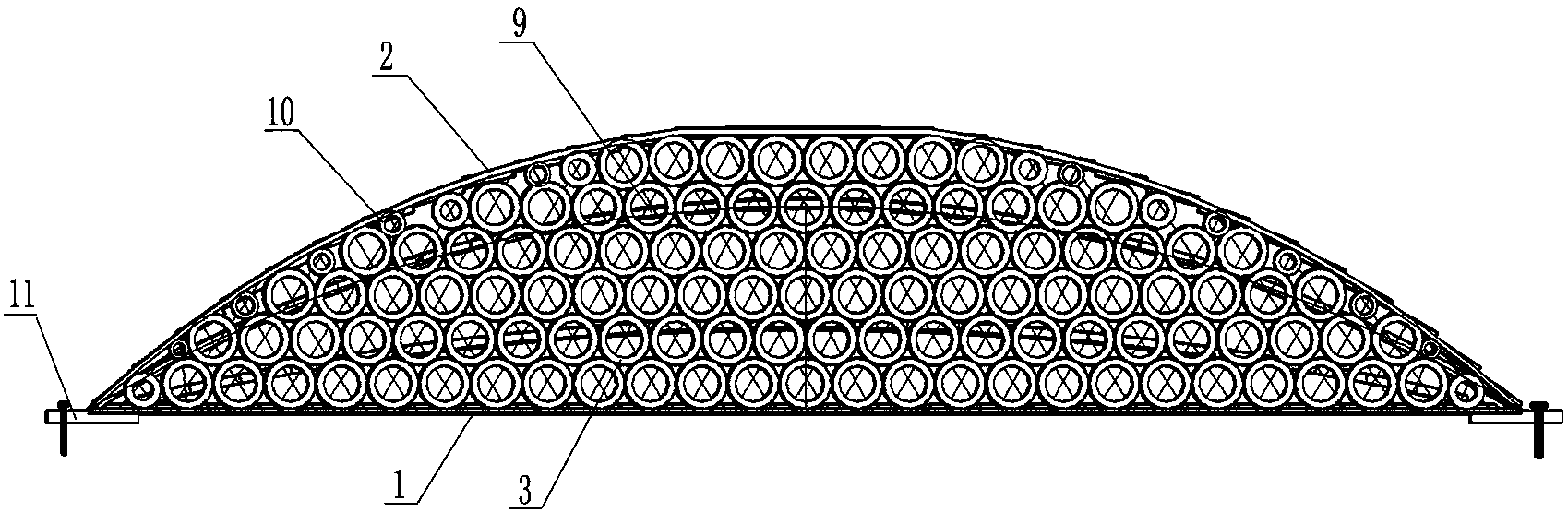

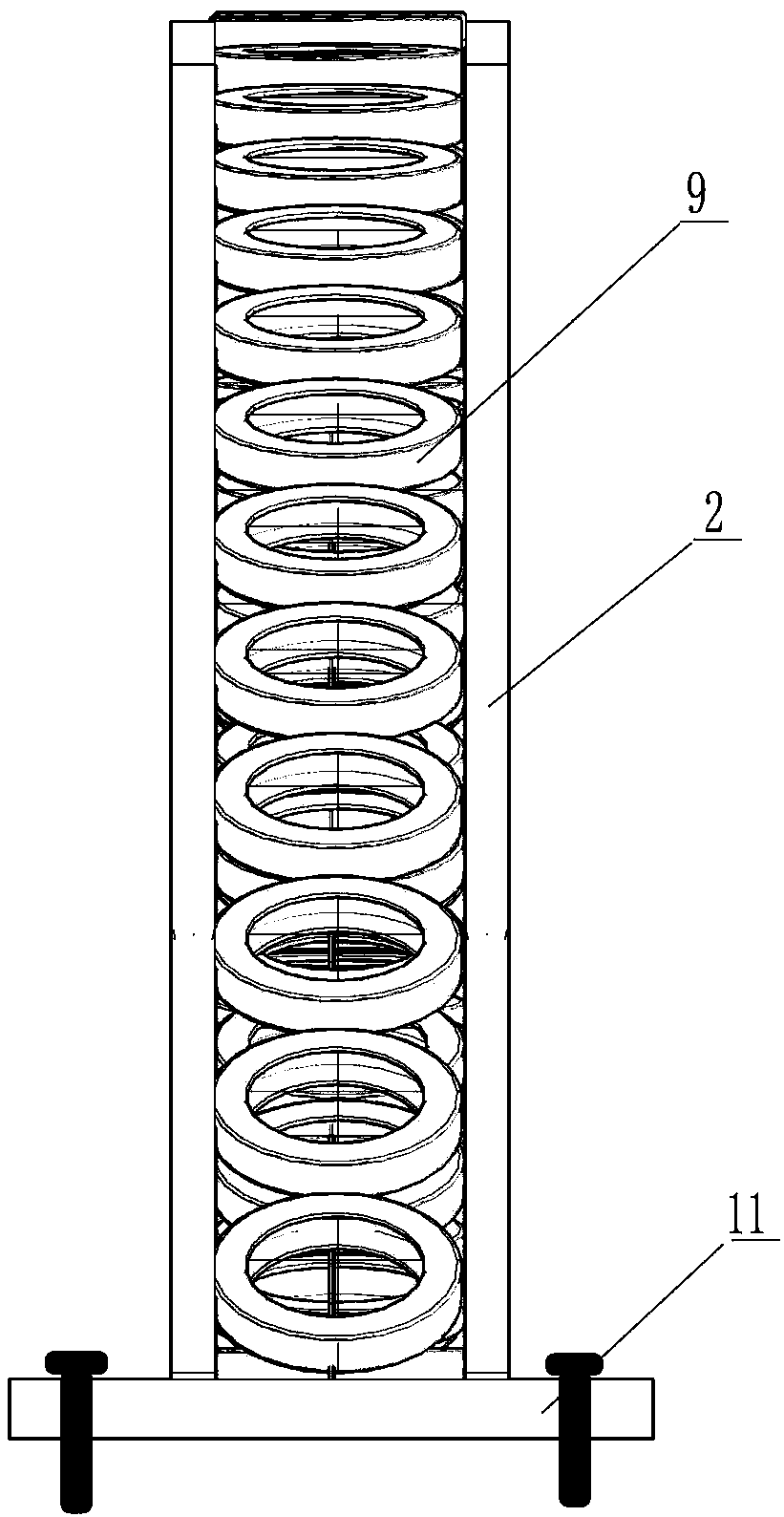

[0032] Embodiment 1: the first kind of waste tire truss, see Figure 1-Figure 4 , a truss formed by two parallel and adjacent top beams 2 and bottom beams 1, and the top beam 2 is an arched structure. The junction of the top beam and the bottom beam is finally fixed in the foundation.

[0033] Vertical tires 3 are fully filled between the roof beams 2 and bottom beams 1 on each side, while horizontal tires 9 are filled between adjacent two roof beams 2 and two adjacent bottom beams 1, and between adjacent two bottom beams 1 Horizontal tires 9 are filled between the vertical tires 3 .

[0034] Between the adjacent vertical tires 3, a transverse steel strand 4 is penetrated laterally and prestressed, and an oblique steel strand one 5 and an oblique steel strand two 6 are penetrated obliquely and prestressed, so that Each vertical tire 3 generates outward tension, sufficient pressure is generated between adjacent vertical tires 3, sufficient pressure is generated between the ve...

Embodiment 2

[0038]Embodiment 2: the second kind of waste tire truss, see Figure 5 and Figure 6 , the content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that the top beam 2 is a trapezoidal structure.

Embodiment 3

[0039] Embodiment 3: the third kind of waste tire truss, see Figure 7-Figure 9 , the content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that the top beam 2 is a triangular structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com