Unmarked guided-mode resonance Brewster sensor detection device

A technology of guided mode resonance and detection device, which is applied in the measurement of phase influence characteristics, etc., can solve the problems of small movement and the detection sensitivity of the sensor does not meet the required requirements, and achieves the effect of high integration and improved sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

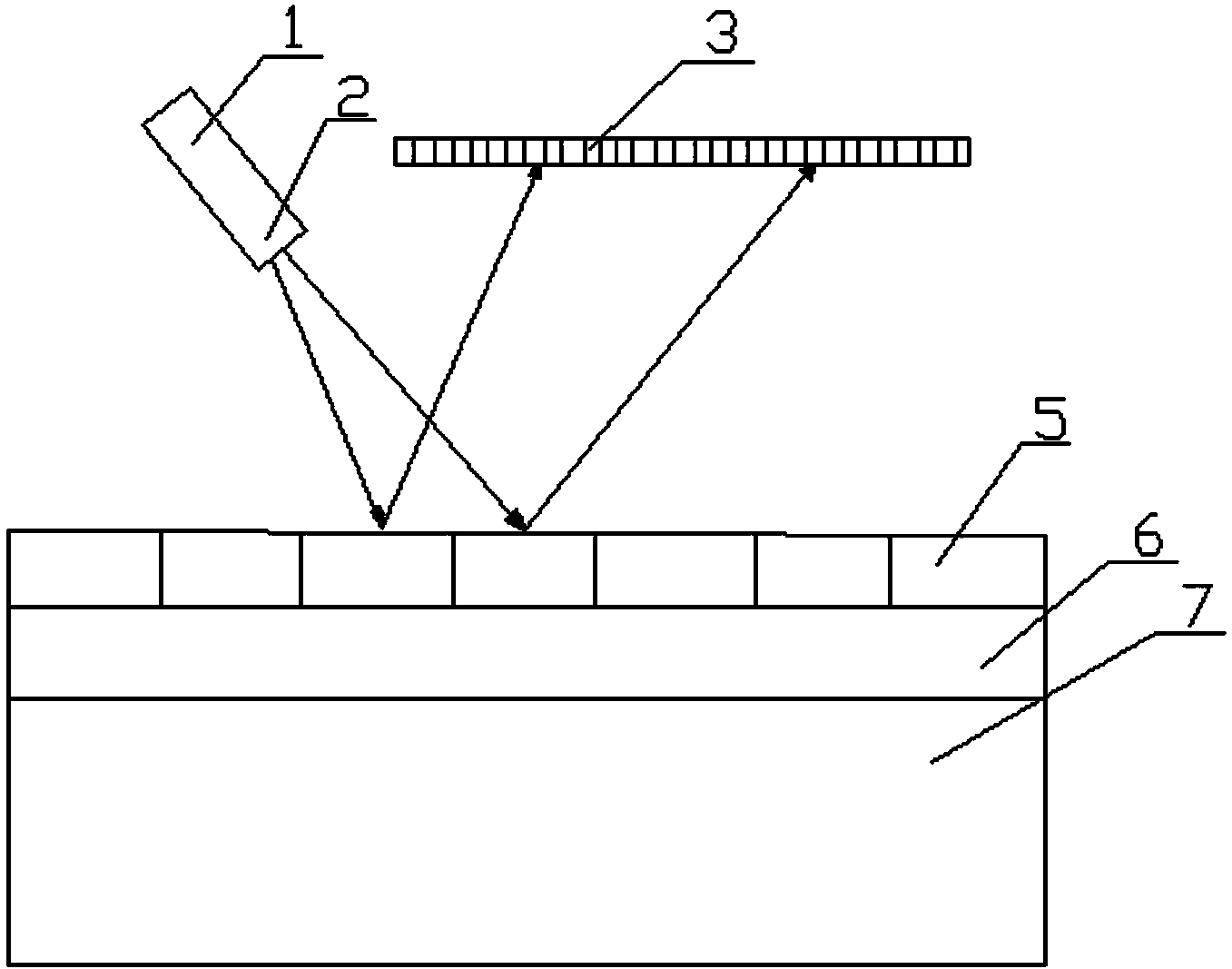

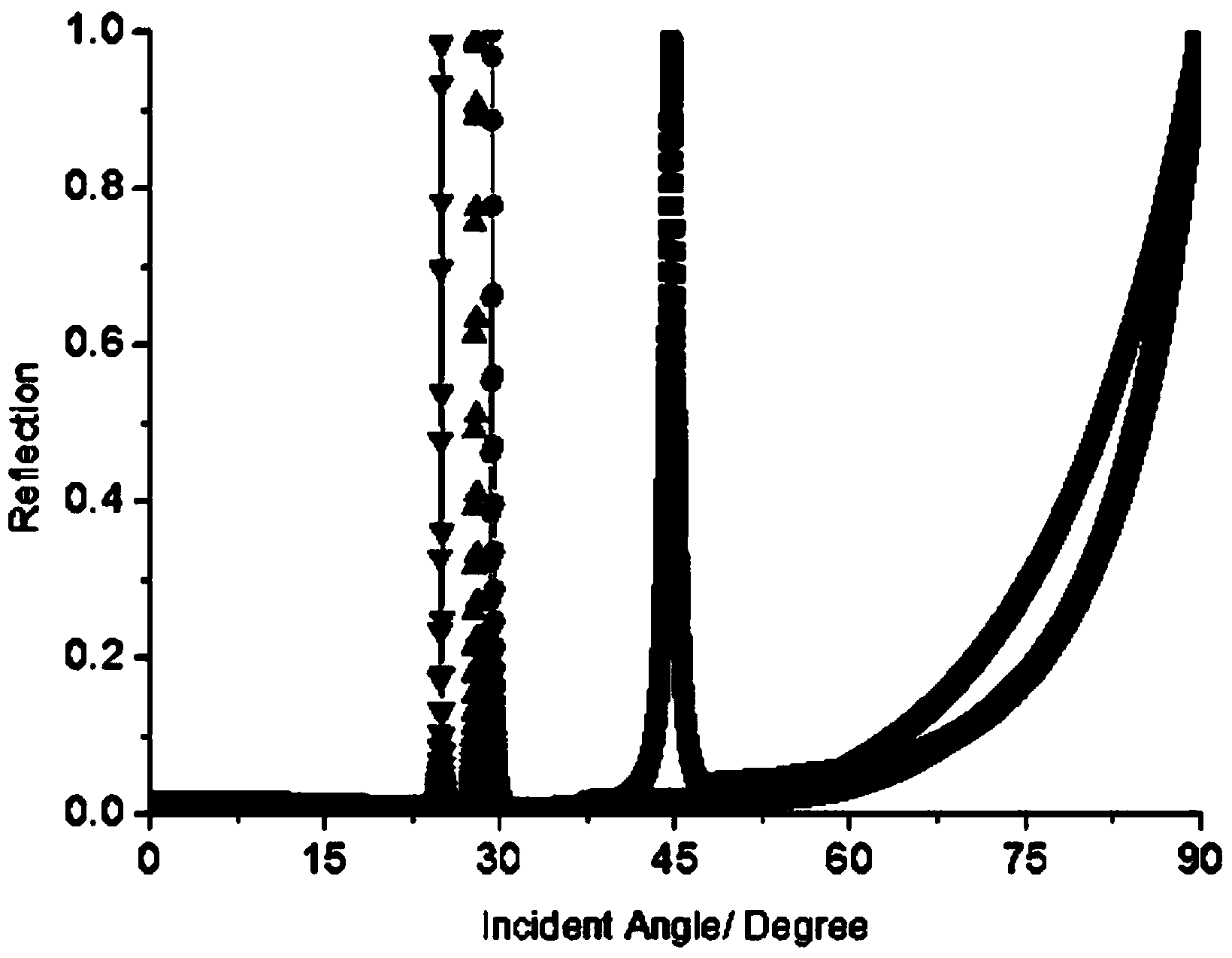

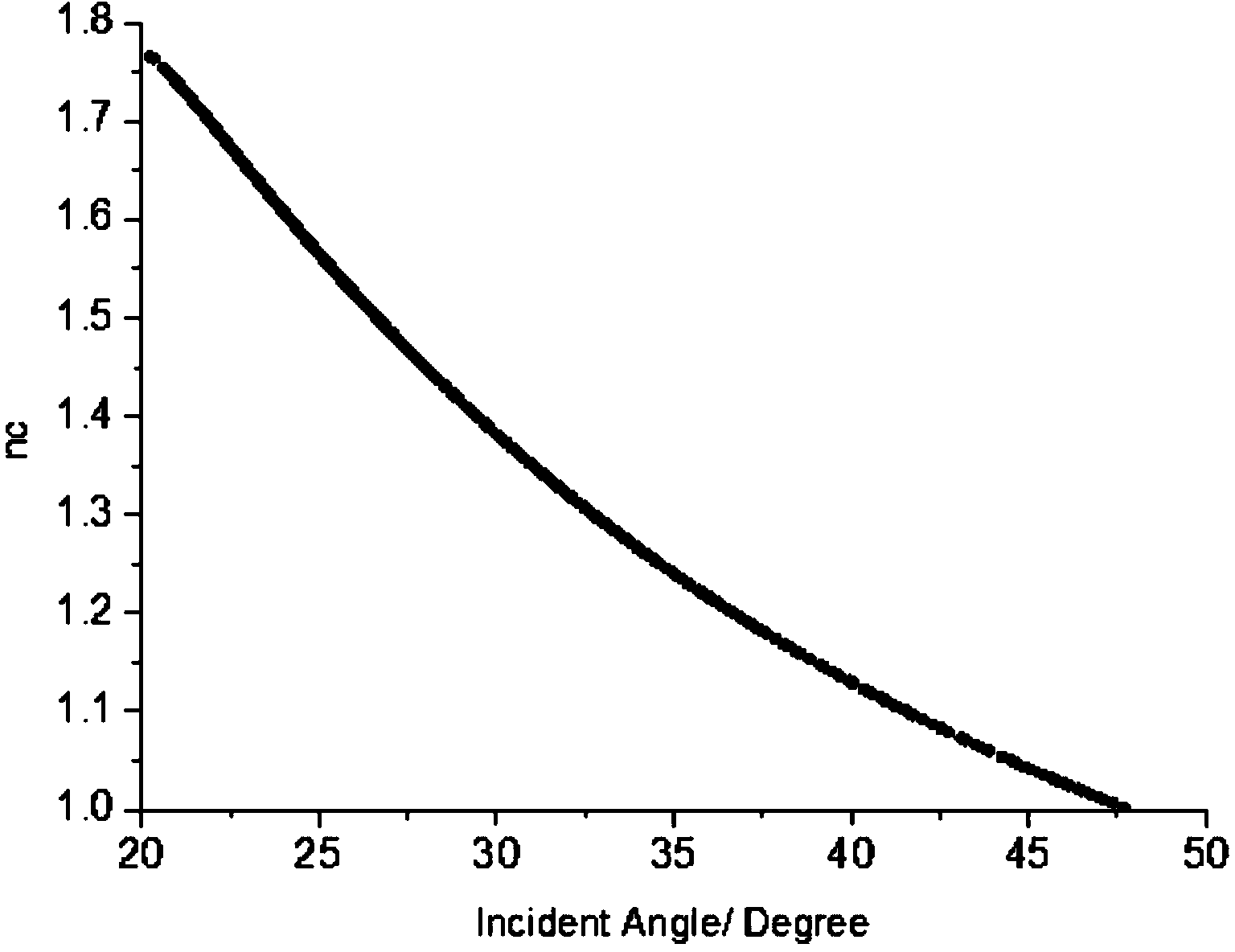

[0019] 1) Turn on the switch of the incident light source component, the guided mode resonant grating sensor and the detection optical component; 2) The laser light source 1 generates the incident light, which is obliquely incident on the grating layer 5 of the guided mode resonant grating sensor through the beam expander group 2, and then passes through Guided mode resonance is generated after the waveguide layer 6 and the substrate 7; 3) The air with a refractive index of 1 is closely combined with the guided mode resonant grating sensor, and the CCD line array 3 detects the laser signal at a resonance angle position of 44.68°.

Embodiment 2

[0021] 1) Turn on the switch of the incident light source component, the guided mode resonant grating sensor and the detection optical component; 2) The laser light source 1 generates the incident light, which is obliquely incident on the grating layer 5 of the guided mode resonant grating sensor through the beam expander group 2, and then passes through Guided mode resonance is generated after the waveguide layer 6 and the substrate 7; 3) The water with a refractive index of 1.333 is closely combined with the guided mode resonant grating sensor, and the CCD line array 3 detects the laser signal at a resonance angle position of 30.22°.

Embodiment 3

[0023] 1) Turn on the switch of the incident light source component, the guided mode resonant grating sensor and the detection optical component; 2) The laser light source 1 generates the incident light, which is obliquely incident on the grating layer 5 of the guided mode resonant grating sensor through the beam expander group 2, and then passes through Guided mode resonance is generated after the waveguide layer 6 and the substrate 7; 3) Isopropanol with a refractive index of 1.377 is closely combined with the guided mode resonant grating sensor, and the CCD linear array 3 detects the resonance angle position of the laser signal at 28.63°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com