Water soluble compositions incorporating enzymes, and method of making same

An enzyme composition, water-soluble technology, applied in the direction of detergent composition, organic cleaning composition, chemical instruments and methods, etc., can solve the problems of low enzyme activity and reduced storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0136] Colorimetric measurement of protease activity

[0137] The protease used is known to catalyze N,N-dimethylcasein (DMC). By hydrolysis of peptide bonds, carboxylic acids and primary amines are produced. The resulting amine reacts with trinitrobenzenesulfonic acid (TNBS) under basic conditions to form a colored complex. Colored complexes are detected at 405nm. The reaction between primary amines and TNB is assumed to be faster than the cleavage of DMC. Therefore, the reaction in the presence of excess substrate can be assumed to be a function of enzyme concentration only.

[0138] Protease activity was determined relative to enzyme standards. A standard is a sample of the raw material protease composition used to prepare the membrane composition according to the examples herein. Results are reported in convenient units of enzyme activity such as catal (Eur. J. Biochemistry, Vol. 97, 319-320, 1979). Using enzymes of known activity, prepare a set of standards by seri...

example 1

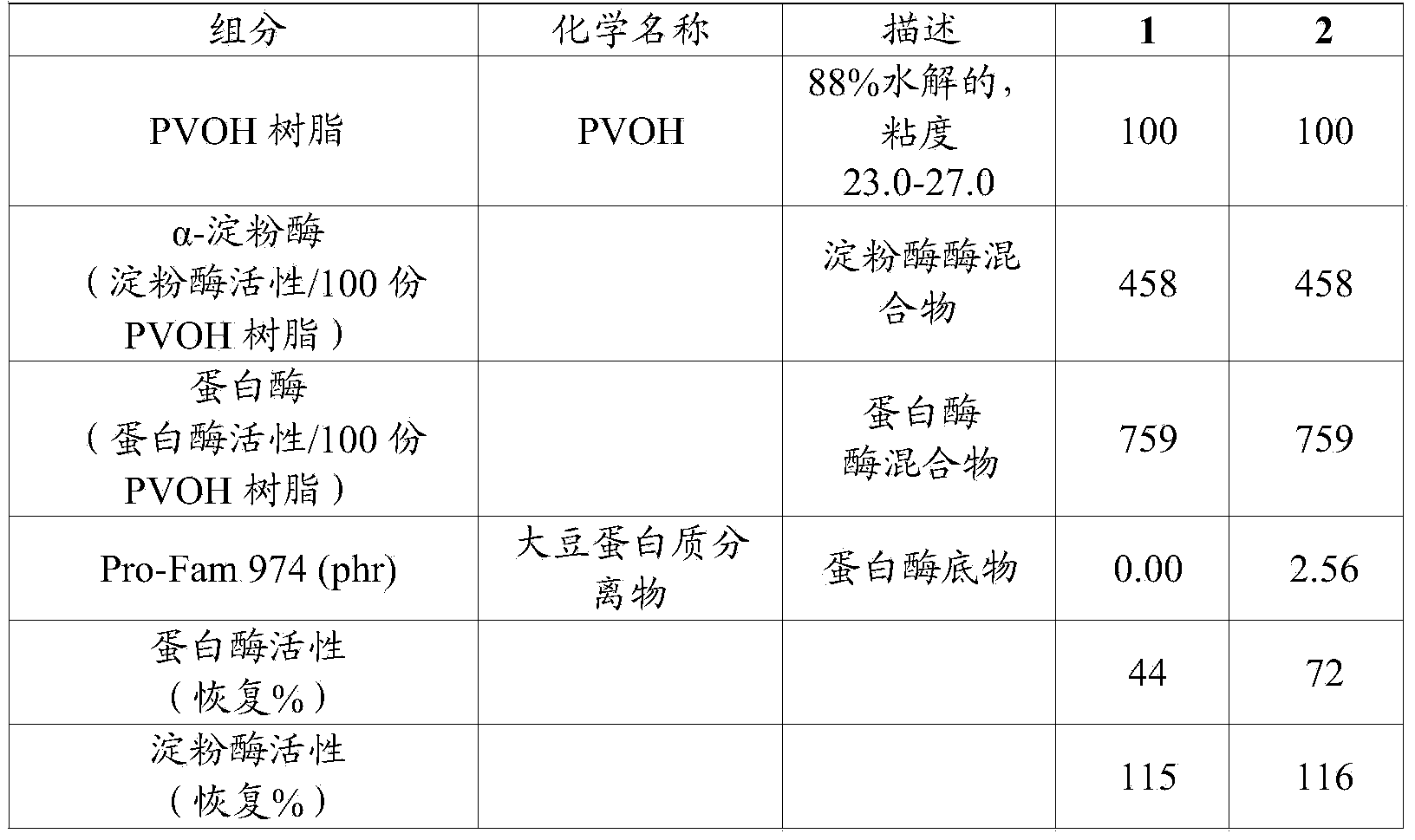

[0146] Using the ingredients identified in the table below and in the instructions, a set of water soluble films was prepared in the amounts indicated. Amounts are expressed in phr unless otherwise stated.

[0147]

[0148] Each membrane also includes about 35phr plasticizer, 390phr water and small amounts of one or more processing aids which are not considered to interfere with enzyme recovery, such as antiblocking agents, surfactants, caustic soda, membrane Forming agents, anti-foaming agents, anti-yellowing agents, etc., in amounts totaling less than about 2.5 phr. A water soluble film according to Formulation 1 was prepared as follows. In a beaker, the processing aid and water were agitated for 10 minutes. A water-soluble resin is added to the mixture, and the mixture is heated. The solution was boiled for 30 minutes. The solution was degassed overnight in an oven at 65 °C. The enzyme, plasticizer and additional water are mixed into the solution at a temperature no...

example 2

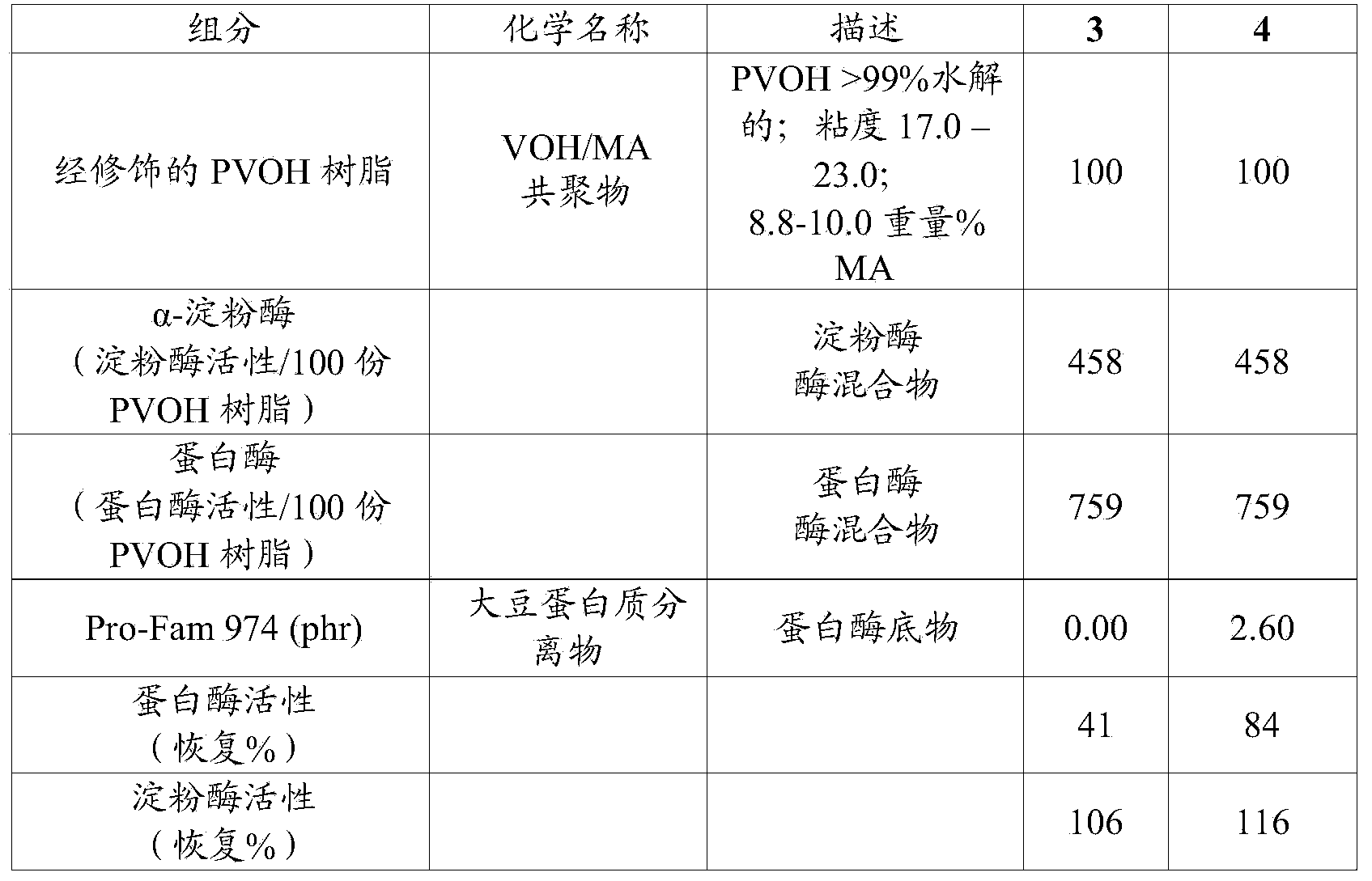

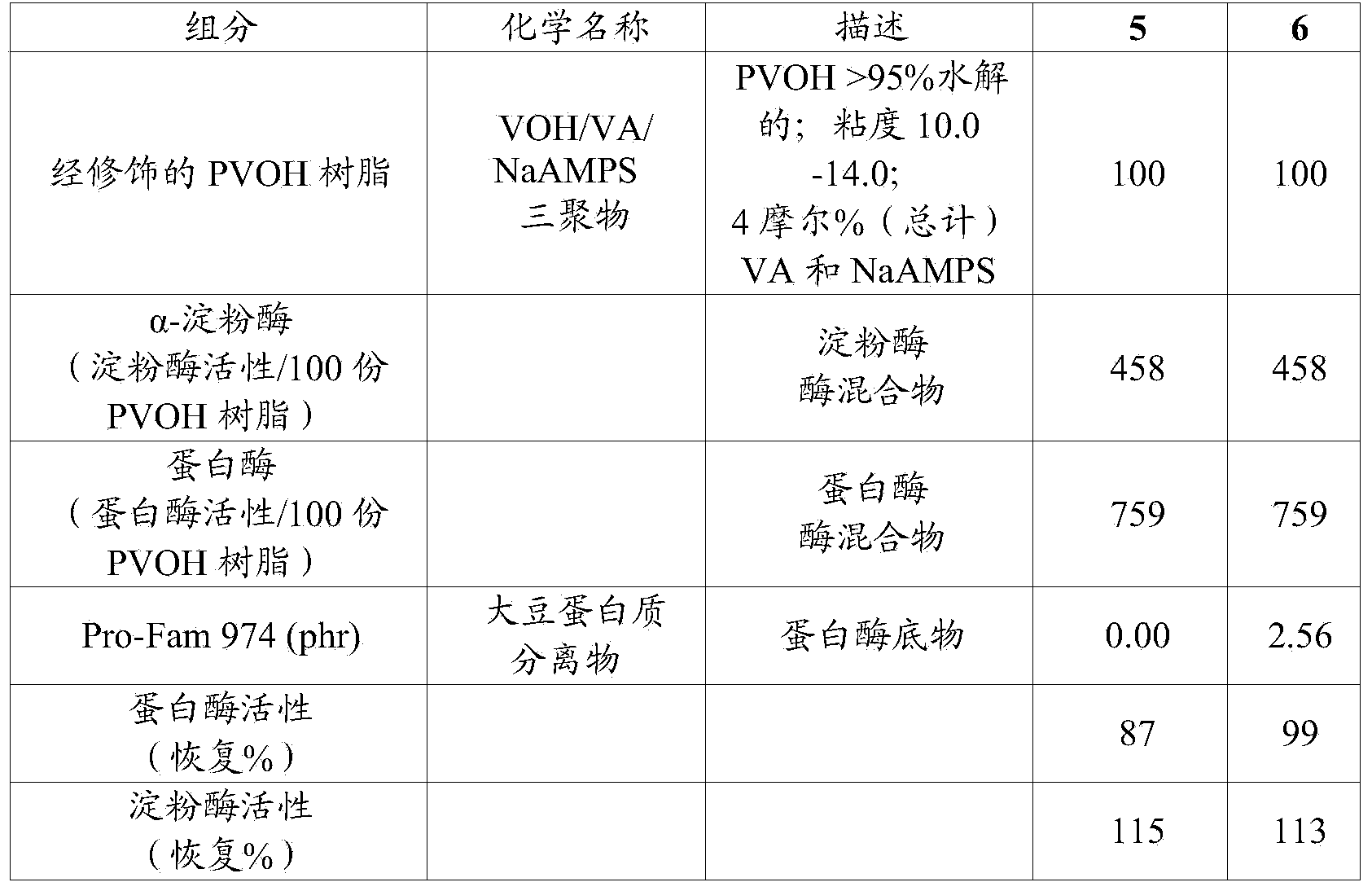

[0152] Using the ingredients identified in the table below and in the instructions, a set of water soluble films was prepared in the amounts indicated. Amounts are expressed in phr unless otherwise stated.

[0153]

[0154] Each membrane also includes approximately 35phr plasticizer, 400phr water and small amounts of one or more processing aids which are not considered to interfere with enzyme recovery, such as antiblocking agents, surfactants, caustic soda, membrane Forming agents, defoamers, anti-yellowing agents, etc., in amounts totaling less than about 6 phr. Follow the operation of Example 1. The percent recovery of enzyme activity in water-soluble films based on vinyl alcohol / methyl acrylate copolymers was determined as follows. The water soluble membrane without enzyme substrate, Membrane 3, demonstrated 41% recovery of protease activity. The water soluble membrane containing the protease substrate, membrane 4, demonstrated 84% recovery of protease activity. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com