Natural coir sole and production method thereof and shoes with soles

A coconut fiber and natural technology, applied in the field of shoe soles and shoe manufacturing, can solve the problems of rough manufacturing process, poor sole wear resistance, poor surface flatness, etc., and achieve the effect of maintaining heat conduction balance, avoiding athlete's foot, and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

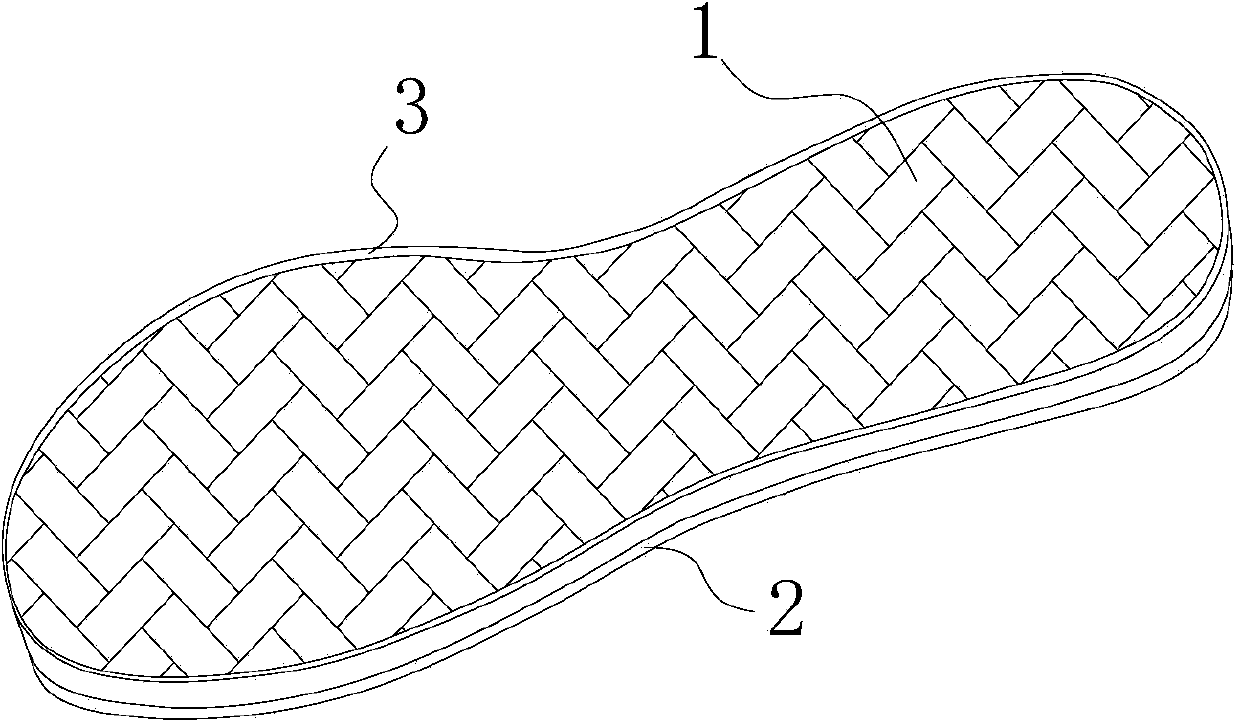

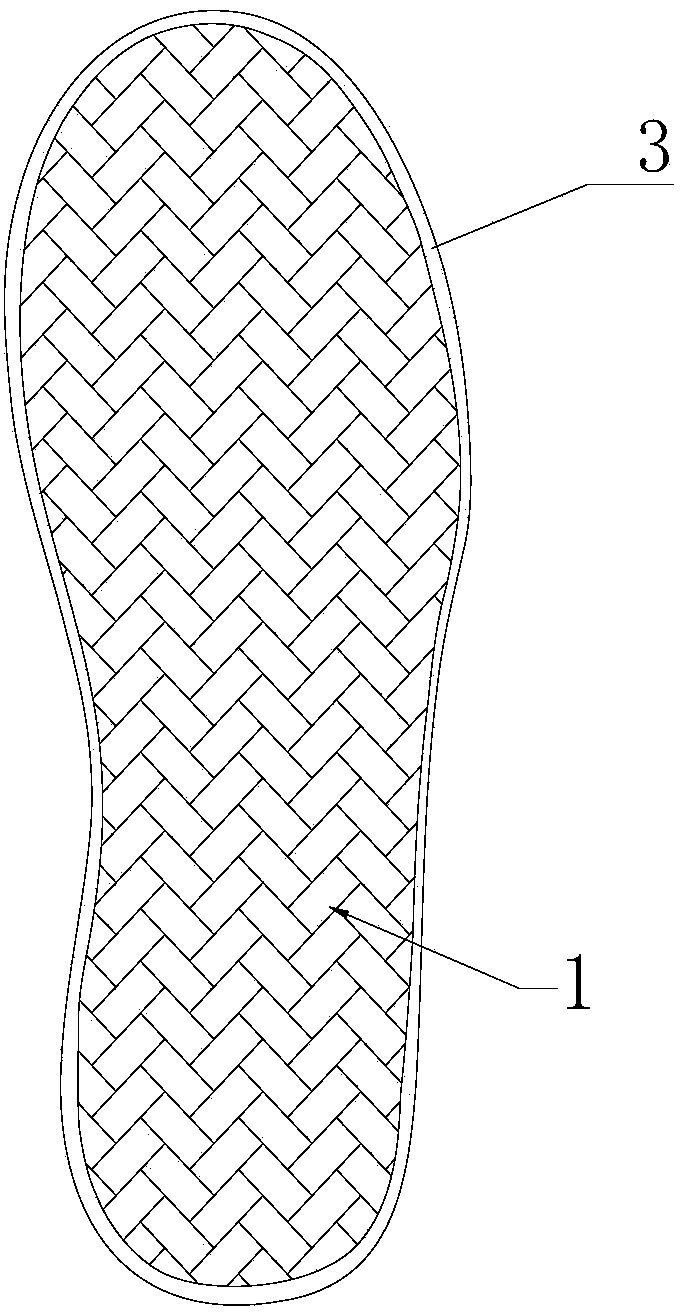

[0044] Such as figure 1 , figure 2 As shown, the natural coir fiber sole of the present invention comprises a large bottom 2 made of natural rubber mixed material and a midsole 1 made of natural coir fiber, and the midsole 1 is attached to the outsole 2, on the side of the midsole 1, a protective edge 3 is pasted along its periphery, and the protective edge is a coarse cloth strip; the natural rubber mixed material is formed by mixing natural rubber and calcium carbonate powder, wherein The mass ratio of natural rubber and calcium carbonate powder is 1:0.5;

[0045] Its preparation method is as follows:

[0046] 1) The production of the midsole is carried out in accordance with the following steps

[0047] Opening and carding: After the coconut shell is soaked in alkaline solution, it is rolled, opened, vacuumed, and carded in turn with a carding machine to remove the uneven coconut shell. After drying, it is combed into silk by a carding machine to obtain coconut shell. ...

Embodiment 2

[0060] Such as figure 1 , figure 2 As shown, the natural coir fiber sole of the present invention comprises a large bottom 2 made of natural rubber mixed material and a midsole 1 made of natural coir fiber, and the midsole 1 is attached to the outsole 2, on the side of the midsole, a protective edge 3 is pasted along its periphery, and the protective edge is a hemp rope; the natural rubber mixed material is formed by mixing natural rubber and calcium carbonate powder, wherein natural The mass ratio of rubber to calcium carbonate powder is 1:1;

[0061] Its preparation method is as follows:

[0062] 1) The production of the midsole is carried out in accordance with the following steps

[0063] Opening and carding: After the coconut shell is soaked in alkaline solution, it is rolled, opened, vacuumed, and carded in turn with a carding machine to remove the uneven coconut shell. After drying, it is combed into silk by a carding machine to obtain coconut shell. Fiber silk; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com