A kind of natural coir fiber sole and its preparation method and shoes with the sole

A coconut fiber and natural technology, applied in the field of shoe soles and shoe manufacturing, can solve the problems of poor surface flatness, rough manufacturing process, difficult large-scale production, etc., and achieve the effects of maintaining heat conduction balance, avoiding athlete's foot, and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

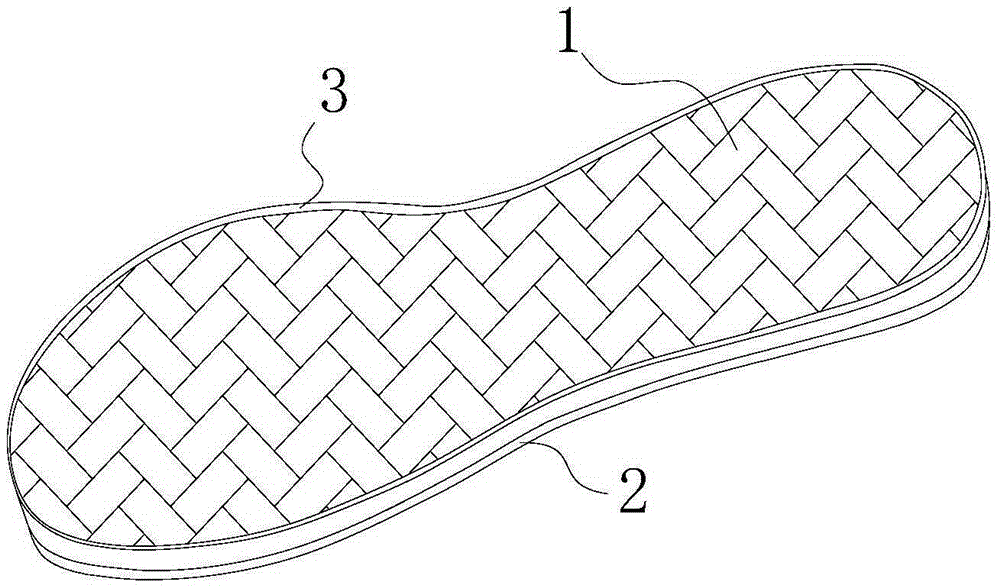

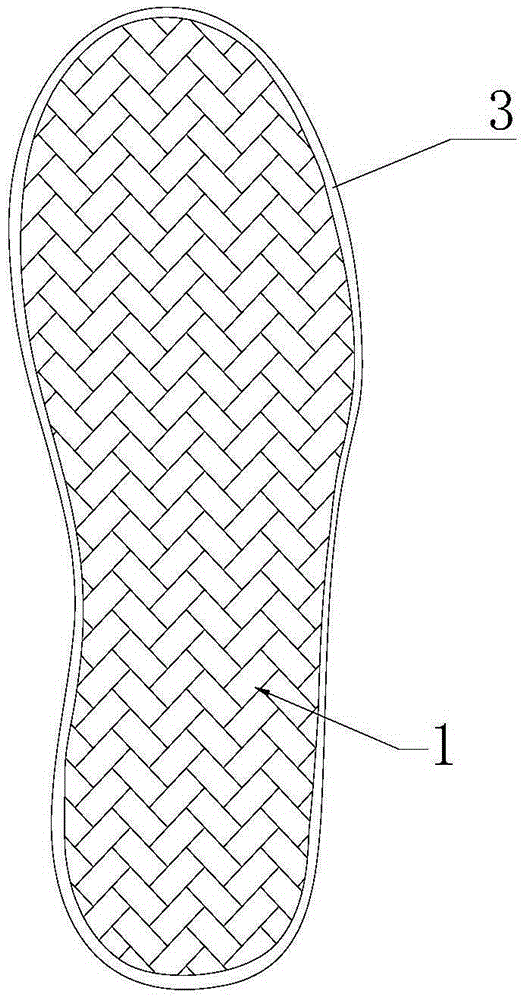

[0044] Such as figure 1 , figure 2 As shown, the natural coir fiber sole of the present invention comprises a large bottom 2 made of natural rubber mixed material and a midsole 1 made of natural coir fiber, and the midsole 1 is attached to the outsole 2, on the side of the midsole 1, a protective edge 3 is pasted along its periphery, and the protective edge is a coarse cloth strip; the natural rubber mixed material is formed by mixing natural rubber and calcium carbonate powder, wherein The mass ratio of natural rubber and calcium carbonate powder is 1:0.5;

[0045] Its preparation method is as follows:

[0046] 1) The production of the midsole is carried out in accordance with the following steps

[0047] Opening and carding: After the coconut shell is soaked in alkaline solution, it is rolled, opened, vacuumed, and carded in turn with a carding machine to remove the uneven coconut shell. After drying, it is combed into silk by a carding machine to obtain coconut shell. ...

Embodiment 2

[0060] Such as figure 1 , figure 2 As shown, the natural coir fiber sole of the present invention comprises a large bottom 2 made of natural rubber mixed material and a midsole 1 made of natural coir fiber, and the midsole 1 is attached to the outsole 2, on the side of the midsole, a protective edge 3 is pasted along its periphery, and the protective edge is a hemp rope; the natural rubber mixed material is formed by mixing natural rubber and calcium carbonate powder, wherein natural The mass ratio of rubber to calcium carbonate powder is 1:1;

[0061] Its preparation method is as follows:

[0062] 1) The production of the midsole is carried out in accordance with the following steps

[0063] Opening and carding: After the coconut shell is soaked in alkaline solution, it is rolled, opened, vacuumed, and carded in turn with a carding machine to remove the uneven coconut shell. After drying, it is combed into silk by a carding machine to obtain coconut shell. Fiber silk; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com