Cyclone purification method and device for cooling water of purification loop of reactor pit of a pressurized water reactor nuclear power plant

A technology for pressurized water reactor nuclear power plants and purification circuits, applied in chemical instruments and methods, separation methods, filter circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Removing Solid Particle Impurities Using Micro-Swirl Flow Separation Package in Purification Circuit of Reactor Pool

[0059] 1. Implementation process

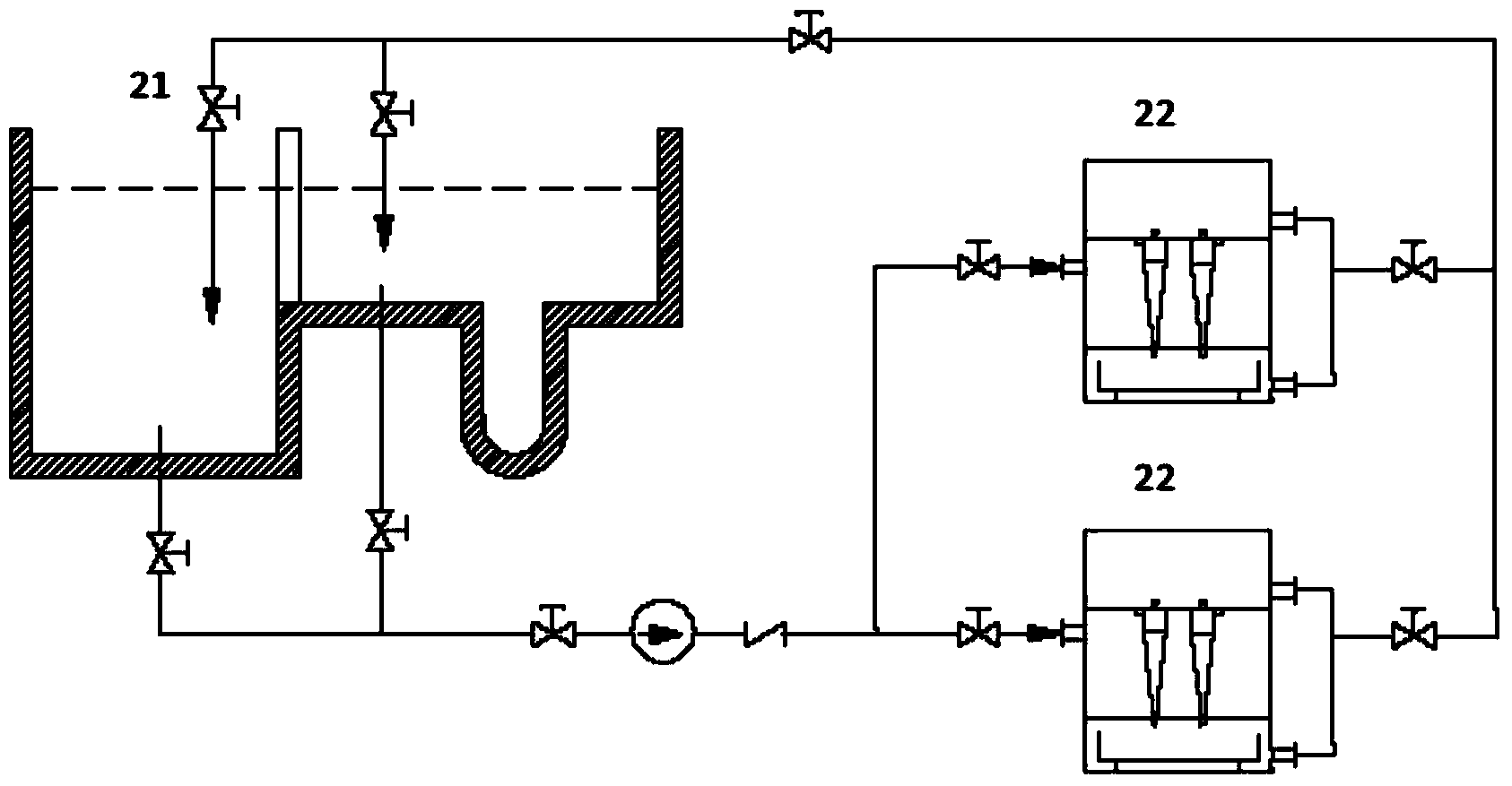

[0060] Such as figure 2 shown.

[0061] 2. Key equipment

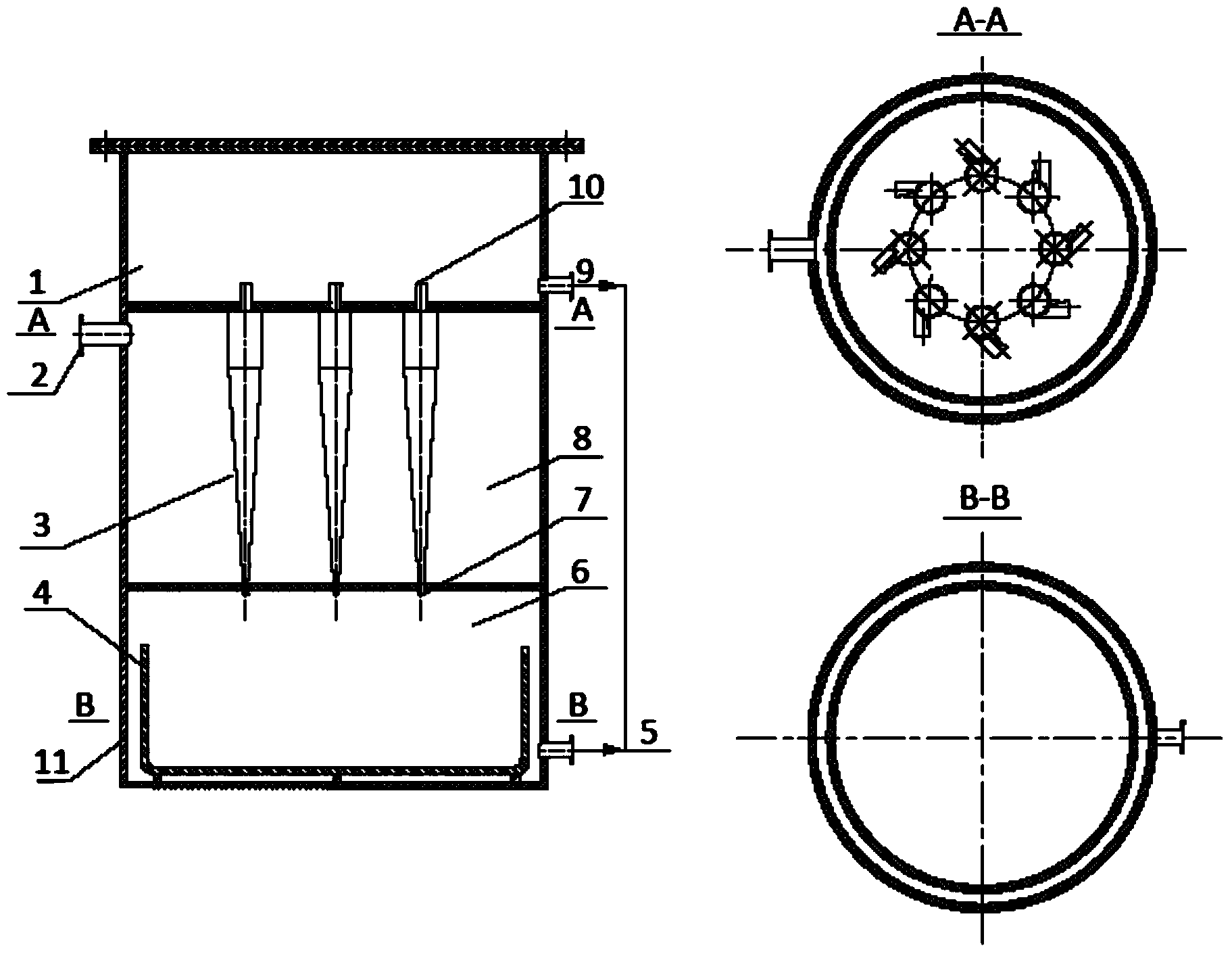

[0062] The key equipment in this technological process is a complete set of micro-swirl separation device coupled with a micro-swirl core tube and a filter ash hopper. Among them, the side-by-side vertical micro-swirl core tube assembly is placed in the micro-swirl separation device, and the filter ash hopper is placed at the bottom of the micro-swirl separation device to connect with the bottom flow of the micro-swirl core tube. The processing capacity of the equipment is 10m 3 / h, the external dimension is Φ600×2400. The top is closed with a tube plate type, and the movable ash hopper is used to facilitate the subsequent replacement of the ash hopper.

[0063] 3. Control

[0064] Under full load conditions, the circulation flow of the process is 10m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap