Plastic bottle cap multi-station automatic printing detection connection machine

An automatic printing, multi-station technology, applied to printing machines, rotary printing machines, printing, etc., can solve the problems of no automatic detection and rejection of defective products, high labor intensity, low work efficiency, etc. The effects of promotional use, low labor intensity and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. As a part of the present specification, the principles of the present invention will be illustrated by examples. Other aspects, features and advantages of the present invention will become apparent from the detailed description. In the figures to which reference is made, the same reference numerals are used for the same or similar parts in different figures.

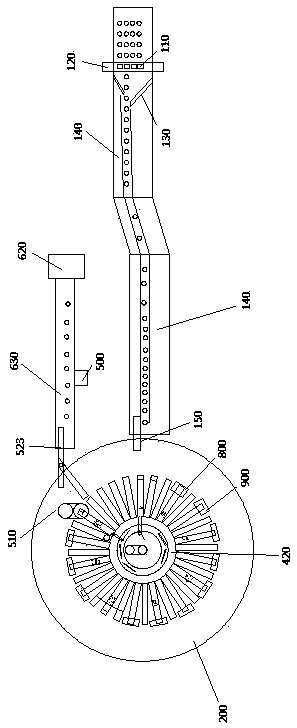

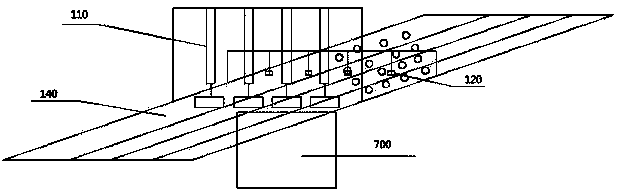

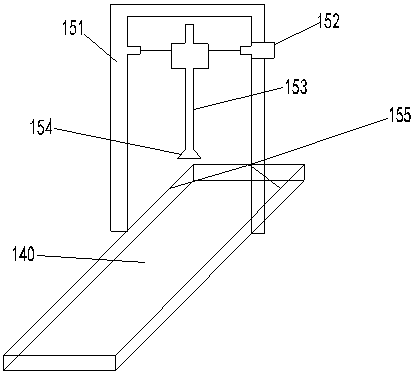

[0025] like figure 1 As shown in the figure, a schematic diagram of the structure of the multi-station automatic printing detection and connection machine for plastic bottle caps according to the preferred embodiment of the present invention, the multi-station automatic printing and detection connection machine for plastic bottle caps according to the preferred embodiment of the present invention includes an automatic capping system 100, multiple The station turntable 200, the bottle cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com