Programming-free welding robot and control method

A technology of welding robots and encoders, which is applied in the direction of program control manipulators, welding equipment, auxiliary welding equipment, etc., can solve problems such as unintelligible programming and affect the promotion and use of robots, so as to reduce the influence of human factors and improve work efficiency , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

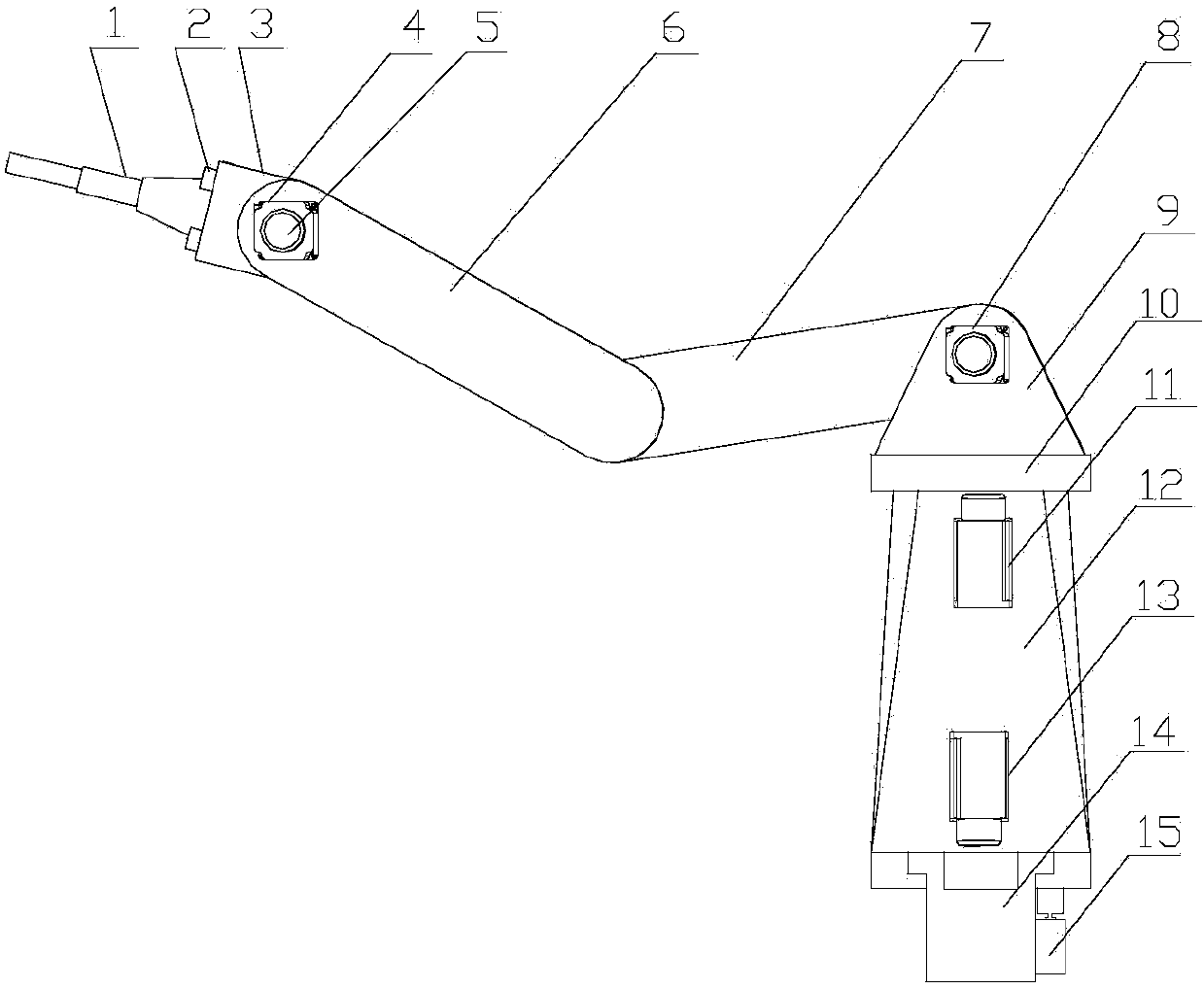

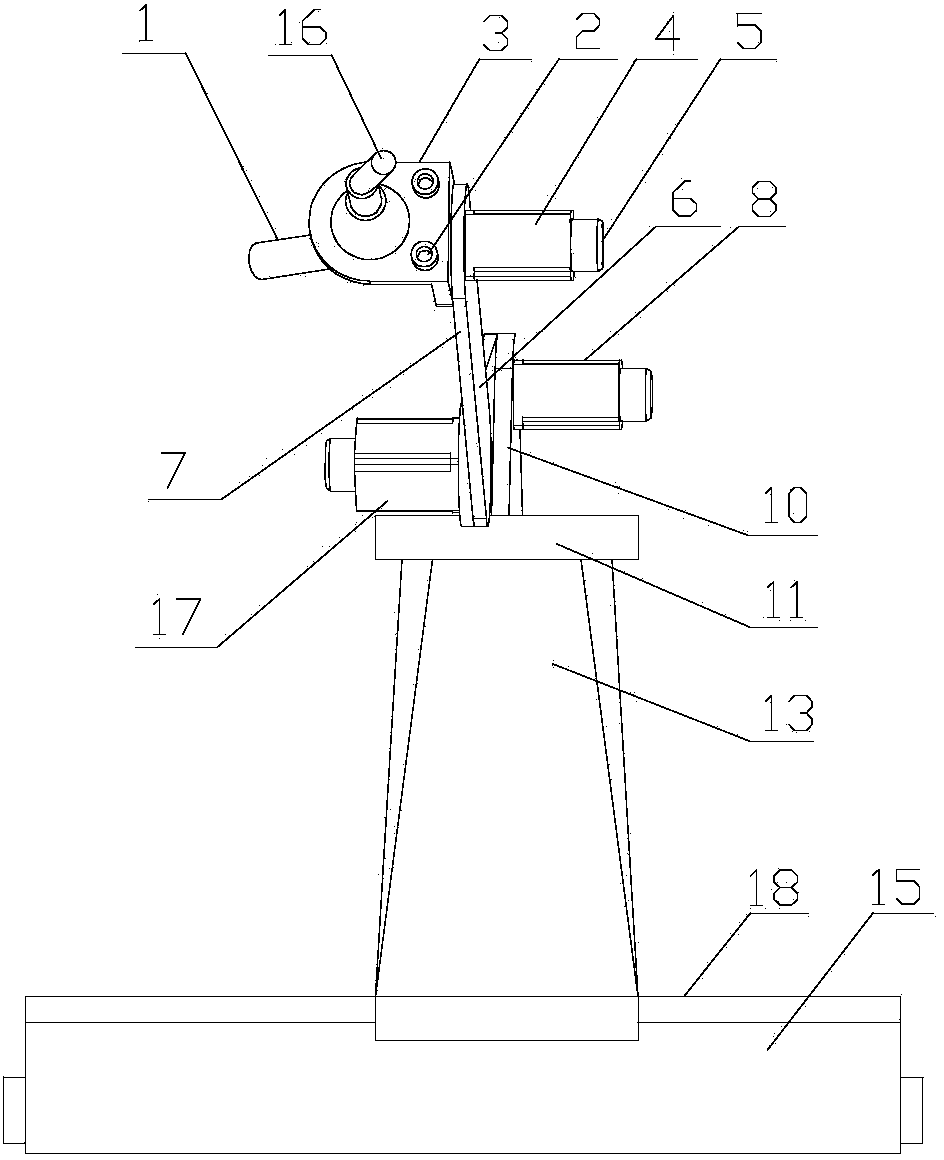

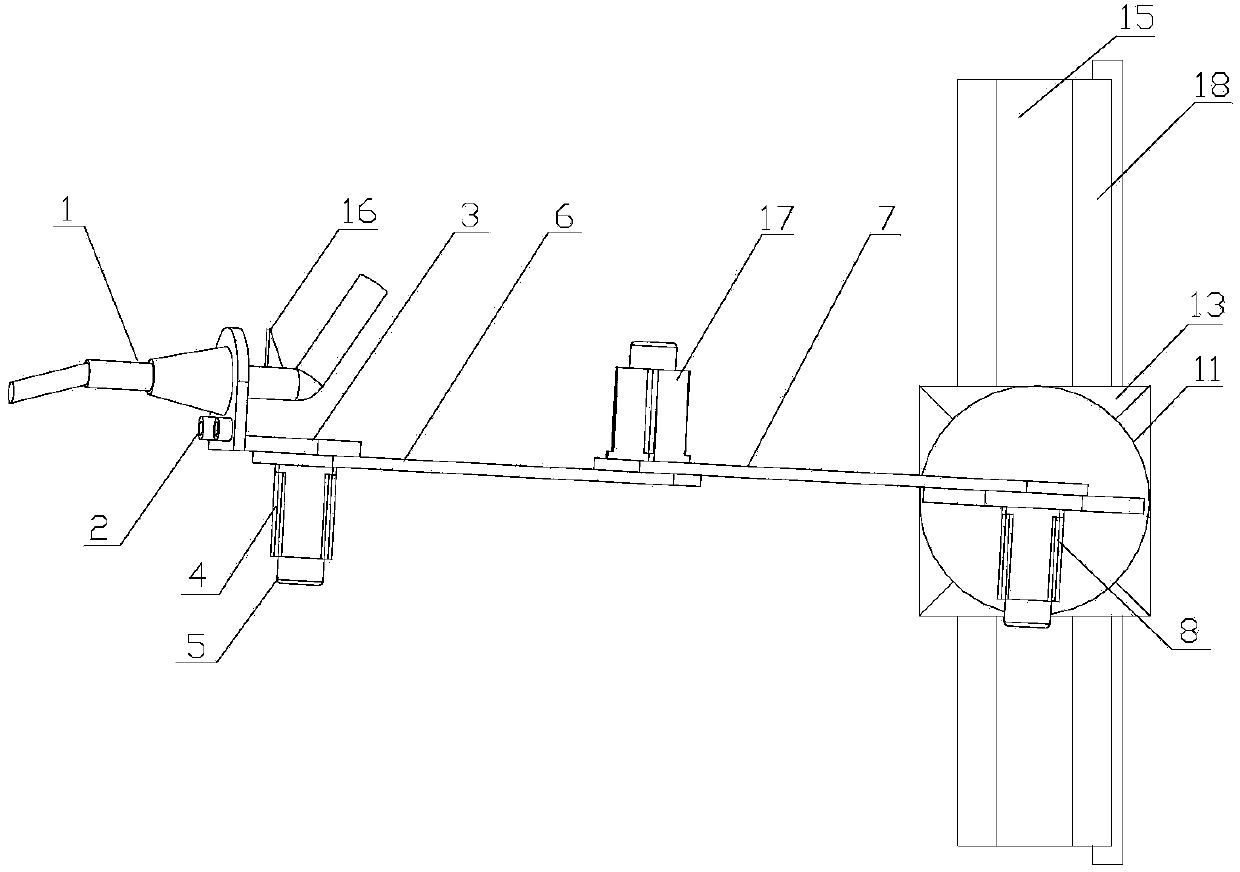

[0021] Depend on figure 1 , 2 , 3, it can be seen that the programming-free welding robot of the present invention is mainly composed of a welding torch 1, a light emitter 2, a wrist 3, a servo motor Ⅰ 4, an encoder 5, a small arm 6, a large arm 7, a servo motor Ⅲ 8, a machine base 9, and a turntable 10. Servo motor Ⅳ11, column 12, servo motor Ⅴ13, base 14, grating ruler 15, optical switch 16, servo motor Ⅱ17, rack 18, driver Ⅰ19, driver Ⅱ20, computer 21, driver Ⅲ22, driver Ⅳ23, cable 24, The driver V25 is composed.

[0022] A servomotor V13 is arranged in the bottom of the column 12, and a gear is connected to the shaft of the servomotor V13. A grating ruler 15 is also installed on one side of the base 14 , and the grating ruler 15 is connected with a computer 21 . Servo motor IV11 is housed inside the top of column 12, and the upper end of column 12 is movably connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com