Special base board for drilling thick copper foil board and preparation method of special base board for drilling thick copper foil board

A technology of thick copper foil plate and backing plate, which is applied in the field of special backing plate for drilling thick copper foil plate and its preparation field, can solve the problems of burr in the drilling of thick copper foil plate and affect the processing quality, etc., and achieve good industrial production value and application prospects, good electrical conductivity, small energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention provides a special backing plate for thick copper foil drilling and its preparation method. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

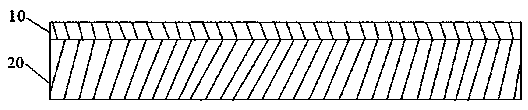

[0020] A method for preparing a special backing plate for drilling thick copper foil boards, wherein the preparation method includes the following steps: mixing the bonding resin and 0-5% by mass fraction of additives evenly, and then applying the roll on the reinforcing material , to make a thick copper foil board special backing plate for drilling holes with the surface layer as the bonding resin layer and the bottom layer as the reinforcing material layer.

[0021] Further, the preparation method of the special backing plate for drilli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com