Sewage treatment method and device by taking zero-valent iron powder as carrier

A sewage treatment method and zero-valent iron technology, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, chemical/physical/physicochemical fixed reactors, etc., can solve the problem of small dispersion distance and low degradation efficiency of organic pollutants and other problems to achieve the effect of avoiding secondary pollution, not easy to rust, and high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

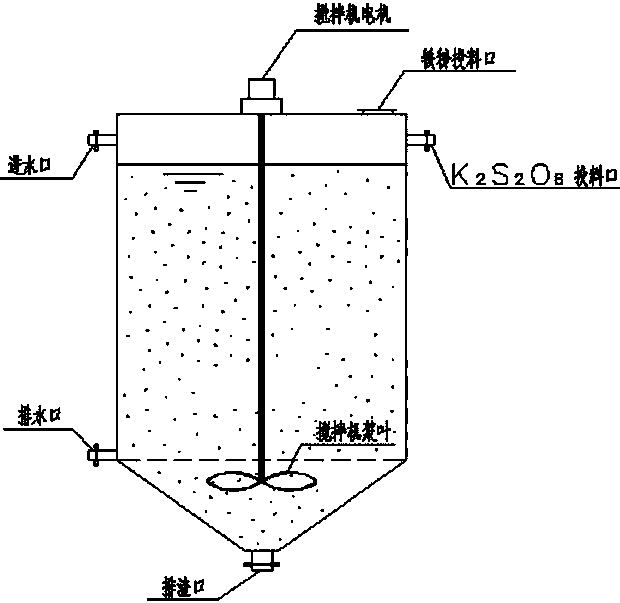

[0027] Example 1: In this example, the volume of the improved sequencing batch reactor is 3.0 L, and sewage is fed in until the volume accounts for 2 / 3 of the reactor capacity. The initial concentration of chloramphenicol (CAP) was 36 mg / L, adding K 2 S 2 o 8 The concentration is 3240 mg / L, and the amount of zero-valent iron powder added is 150 mg. The timing of water intake, feeding, stirring, static settling, drainage and slag discharge is precisely controlled by the time controller. After entering the sewage, add K at the same time 2 S 2 o 8 and zero-valent iron powder, after the addition is completed, start to stir; after stirring for 2 hours, settle for 2 days; discharge slag after draining. The effluent results after operation are: the concentration of CAP in sewage is 0 mg / L, the removal rate of CAP is 100%, and the removal rate of TOC in sewage is 86%.

Embodiment 2

[0028] Example 2: In this example, the volume of the improved sequencing batch reactor is 3.0 L, and sewage is fed until the volume accounts for 7 / 10 of the reactor capacity. The initial concentration of CAP was 40 mg / L, adding K 2 S 2 o 8 The concentration is 6480 mg / L, and the amount of zero-valent iron powder added is 180 mg. The timing of water intake, feeding, stirring, static settling, drainage and slag discharge is precisely controlled by the time controller. After entering the sewage, add K at the same time 2 S 2 o 8 and zero-valent iron powder, after the addition is completed, start stirring; after stirring for 3 hours, settle for 2.5 days; discharge slag after draining. The effluent results after operation are: the concentration of CAP in sewage is 0 mg / L, the removal rate of CAP is 100%, and the removal rate of TOC in sewage is 89%.

Embodiment 3

[0029] Example 3: In this example, the volume of the improved sequencing batch reactor is 3.0 L, and sewage is fed until the volume accounts for 4 / 5 of the reactor capacity. The initial concentration of CAP was 45 mg / L, adding K 2 S 2 o 8 The concentration is 11250 mg / L, and the amount of zero-valent iron powder added is 200 mg. The timing of water intake, feeding, stirring, static settling, drainage and slag discharge is precisely controlled by the time controller. After entering the sewage, add K at the same time 2 S 2 o 8 and zero-valent iron powder, after the addition is completed, start stirring; after stirring for 4 hours, settle for 3 days; drain and discharge slag. The effluent results after operation are: the concentration of CAP in sewage is 0 mg / L, the removal rate of CAP is 100%, and the removal rate of TOC in sewage is 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com