A multi-piece glass selection device and a method for multi-piece glass at the cold end of a flat glass production line

A flat glass, sheet glass technology, applied in glass production, glass manufacturing equipment, glass transportation equipment and other directions, can solve the problems of unreasonable displacement or displacement of glass, reduced product quality, long transmission distance, etc., to avoid abnormal The effect of displacement, reducing inconsistencies, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The invention relates to a flat glass production line, mainly the cold end of a float glass production line, provides a device for selecting multiple sheets, and provides a method for realizing glass sheet selection by using the device.

[0036] The technical solution of the present invention will be further described in detail with reference to the accompanying drawings.

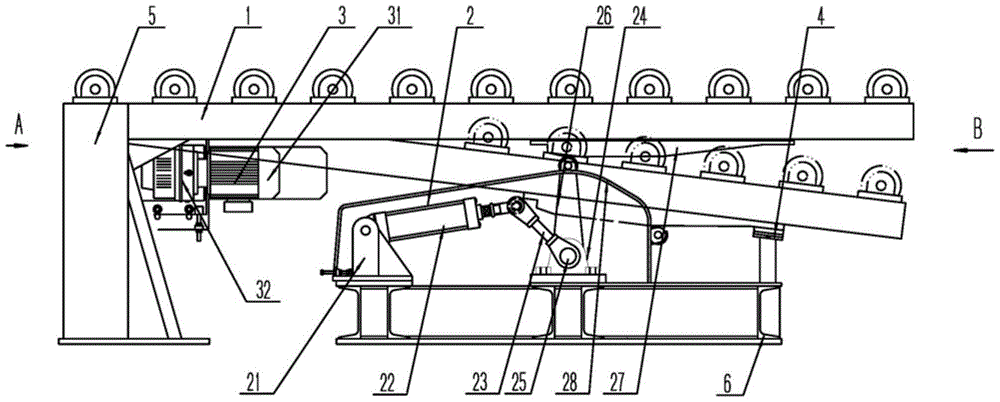

[0037] Such as figure 1 As shown, the device for automatic selection of multiple sheets of flat glass is provided with a suspension roller table 1, a lifting mechanism 2, a transmission mechanism 3, a buffer mechanism 4, a support 5, and a basic platform 6; the following is a detailed description of the composition and interconnection of each part:

[0038] support 5

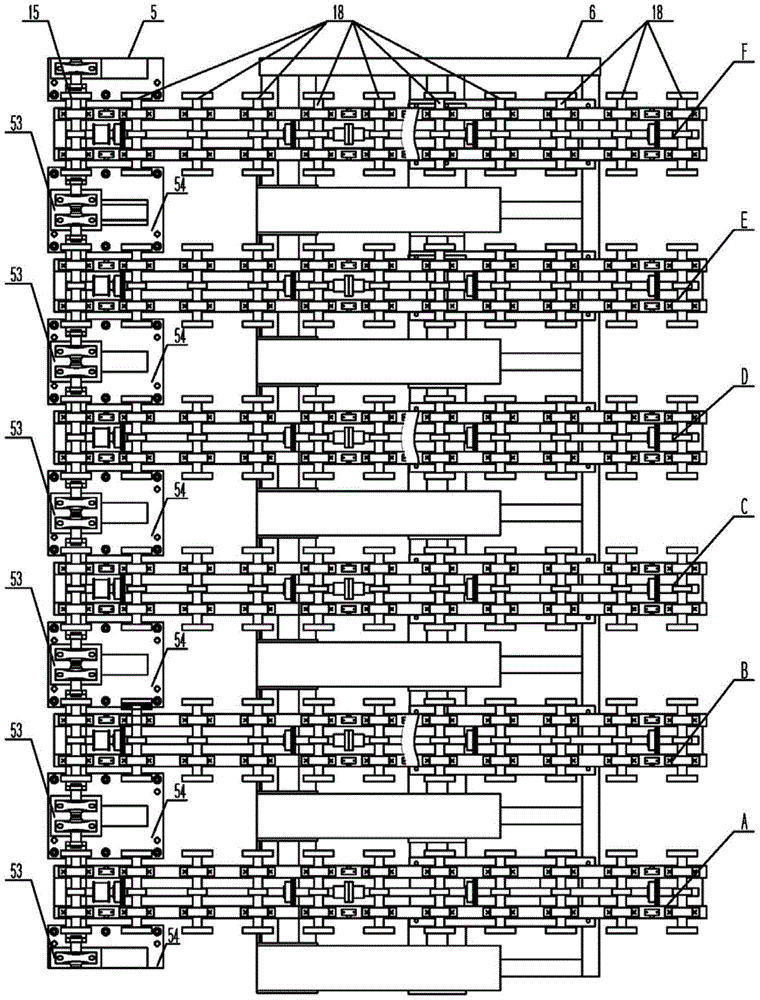

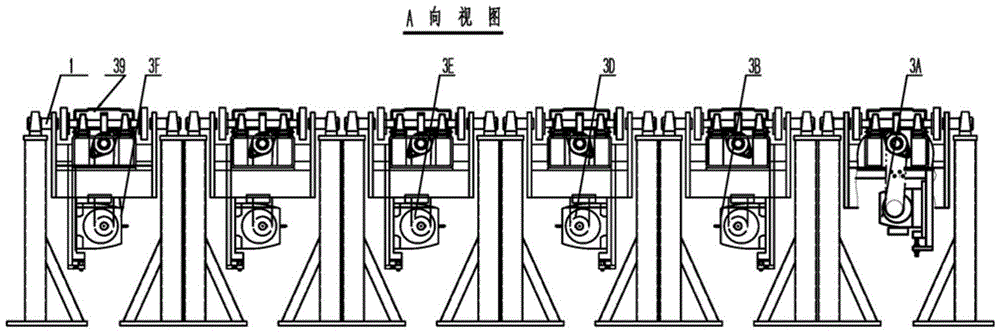

[0039] combine image 3 , Figure 10 As shown, wherein, the support 5 is welded by a rectangular steel vertical beam 51, an oblique support beam 52, and upper and lower steel plates 53, 54 (see A and C), and the upper steel plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com