Antique brick and production method thereof

A production method and technology of antique bricks, which are applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as unfavorable energy saving and consumption reduction, and achieve excellent freeze-thaw resistance, pollution prevention, and compression resistance. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

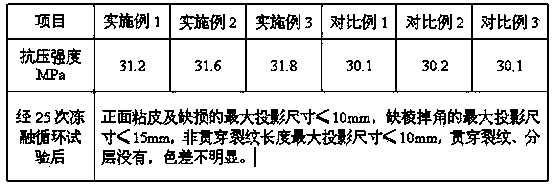

Examples

Embodiment 1

[0032] The raw materials of antique bricks include at least the following materials in parts by weight: 290 parts of cement, 1100 parts of fly ash, 280 parts of corundum, CaCl 2 3.8 parts of early strength agent, 390 parts of slag, 20.5 parts of anti-pressure auxiliary agent, 0.5 parts by weight of iron black, and the anti-pressure auxiliary agent is made of the following materials in parts by weight: 1 part of polyvinyl alcohol, 3.5 parts of styrene-butadiene rubber , 7 parts of propyl p-hydroxybenzoate, and described archaized brick is obtained through the following steps:

[0033] 1) Mix the raw materials according to the ratio, add water, stir evenly, and make a mixture with a moisture content of 0.6wt%;

[0034] 2) Put the mixture into a 2l6×l05×43mm steel mold, and form it by 25Mpa static pressure

[0035] 3) demoulding;

[0036] 4) Curing for 28 days after release from the mold.

Embodiment 2

[0038] The raw materials of antique bricks include at least the following materials in parts by weight: 305 parts of cement, 960 parts of fly ash, 300 parts of quartz sand, CaCl 2 4.2 parts of early strength agent, 370 parts of steel slag, 19.5 parts by weight of anti-pressure auxiliary agent, and 0.8 parts by weight of iron black. The anti-pressure auxiliary agent is made of the following parts by weight: 4 parts of polyvinyl alcohol, 2 part, 5 parts of propyl p-hydroxybenzoate, and described archaized brick is obtained through the following steps:

[0039] 1) Mix the raw materials according to the ratio, add water, stir evenly, and make a mixture with a moisture content of 1.0wt%;

[0040] 2) Put the mixture into a steel mold with 15 pieces / mold, each piece has a size of 2l6×l05×43mm, pressurize and vibrate under a pressure of 21Mpa;

[0041] 3) demoulding;

[0042] 4) Curing for 28 days after release from the mold.

Embodiment 3

[0044] The raw materials of antique bricks include at least the following materials in parts by weight: 300 parts of cement, 1020 parts of fly ash, 150 parts of corundum, 140 parts of quartz sand, CaCl 2 4 parts of early strength agent, 190 parts of slag, 190 parts of steel slag, 20 parts of anti-pressure auxiliary agent, 0.6 part of iron black, and the anti-pressure auxiliary agent is made of the following materials in parts by weight: 2.5 parts of polyvinyl alcohol, styrene-butadiene 2.7 parts of glue, 6 parts of propyl p-hydroxybenzoate, the antique brick is made through the following steps:

[0045] 1) Mix the raw materials according to the ratio, add water, stir evenly, and make a mixture with a moisture content of 0.8wt%;

[0046] 2) Put the mixture into a steel mold with 15 pieces / mold, each piece has a size of 2l6×l05×43mm, pressurize and vibrate under a pressure of 23Mpa;

[0047] 3) demoulding;

[0048] 4) Curing for 28 days after release from the mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com