Room-temperature self-crosslinking wood lacquer emulsion and preparation method thereof

A technology of self-crosslinking and wood varnish, applied in the direction of coating, etc., can solve problems such as poor hardness, falling off, low crosslinking density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

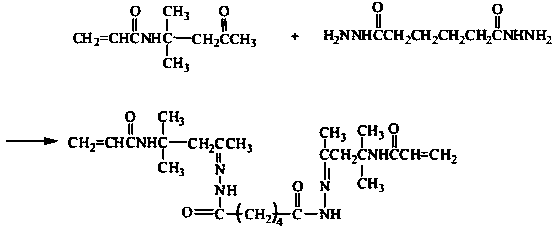

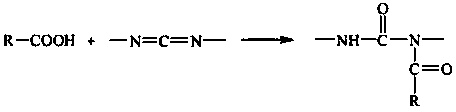

Method used

Image

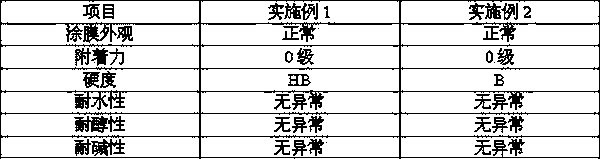

Examples

Embodiment 1

[0026] A preparation method of room temperature self-crosslinking wood paint emulsion, comprising the following steps:

[0027] (1) Add 3.75g of emulsifier (SR-10) and 200g of deionized water into a 1000 mL four-neck flask equipped with a stirring device, a thermometer and nitrogen protection in sequence, stir, raise the temperature to 75°C, and stop heating;

[0028] (2) In an emulsification kettle, dissolve 4.5g of emulsifier (SR-10), 3.5g of sodium styrene sulfonate in 150g of deionized water, then dissolve 98g of methyl methacrylate, 100g of styrene, and 96g of butyl acrylate , 11g of glycidyl methacrylate, 5.6g of methacrylic acid, 8g of diacetone acrylamide, and 0.8g of tert-dodecylmercaptan were added to the emulsifier aqueous solution in a high-speed dispersion state, and stirred for 30-40min to prepare Obtain monomer pre-emulsion;

[0029] (3) Add 5% monomer pre-emulsion to the reaction kettle, add 0.6g sodium persulfate (dissolved in 5g deionized water) aqueous solu...

Embodiment 2

[0034] A preparation method of room temperature self-crosslinking wood paint emulsion, comprising the following steps:

[0035] (1) Add 3.5g SR-10 and 200g deionized water to a 1000mL four-necked flask equipped with a stirring device, a thermometer and nitrogen protection in sequence, stir, raise the temperature to 75°C, and stop heating;

[0036] (2) In an emulsification kettle, dissolve 8.25g SR-10 in 150g deionized water, then mix 93.8g methyl methacrylate, 80g styrene, 102g butyl acrylate, 9g glycidyl methacrylate, 5.9g Add methacrylic acid, 9 grams of diacetone acrylamide, and 1 g of n-dodecyl mercaptan to the emulsifier aqueous solution in a high-speed dispersion state, and stir for 30-40 minutes to obtain a monomer pre-emulsion;

[0037] (3) Add 5% monomer pre-emulsion to the reaction kettle, add 0.5g sodium persulfate (dissolved in 5g deionized water) aqueous solution, and keep warm for 15 minutes.

[0038] (4) When the temperature of the reactor reaches 80°C, add the...

Embodiment 3

[0042] Preparation of water-based wood lacquer: Add 160g of synthetic emulsion into the dispersion kettle, add 1g of pH adjuster AMP-95 under stirring, adjust the pH to 8-9, add 0.8g of defoamer BYK-093, 0.8g Thickener PU337, disperse at 1500 r / min for 15 minutes, add 8g diethylene glycol butyl ether, 8g dipropylene glycol butyl ether, disperse at 1000 r / min for 10 minutes, then add 1.2g H140 substrate wetting agent, 0.2g BYK -028, adjust the viscosity with water, disperse at 1000 r / min for 15 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com