Treatment method of cupriferous sludge

A treatment method and technology for copper metal, applied in the field of treatment of copper-containing metal sludge, can solve the problems of air pollution, high cost, and high energy consumption, and achieve the effect of high recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

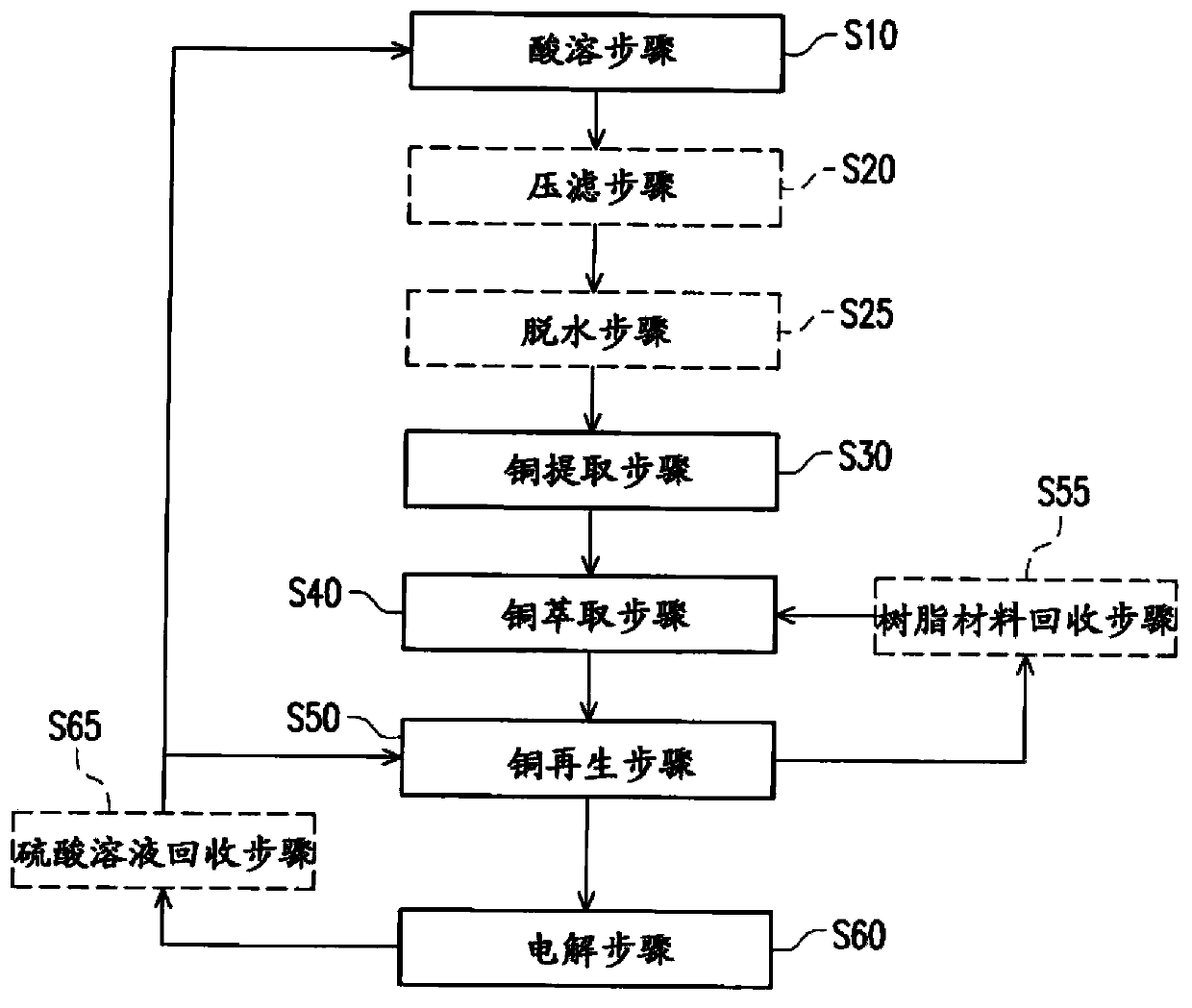

[0021] figure 1 It is a flowchart of a method for treating copper-containing metal sludge according to an embodiment of the present invention. Please refer to figure 1 , in one embodiment, the step S10 of acid-dissolving the copper-containing metal sludge is firstly carried out in, for example, an acidification tank. In the acid dissolution step S10 , the copper-containing metal sludge is dissolved in a sulfuric acid solution to form a first mixture including copper-containing acidified sludge. Copper-containing metal sludge is, for example, sludge produced after an industrial manufacturing process, and substances in the copper-containing metal sludge include copper, iron, nickel, aluminum and other metal substances and other impurities. Therefore, copper sulfate compounds, iron sulfate compounds, nickel sulfate compounds, and aluminum sulfate compounds may be formed after the copper-containing metal sludge reacts with sulfate radicals in sulfuric acid solution. The sulfuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com