Diesel engine exhaust particulate matter trap and trapping method thereof

A technology for particle traps and diesel engines, which is applied to exhaust devices, machines/engines, mechanical equipment, etc., can solve the problems of low trapping efficiency and increase the pore size of the filter element, so as to improve the trapping efficiency and reduce the The effect of air velocity and particle distribution uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

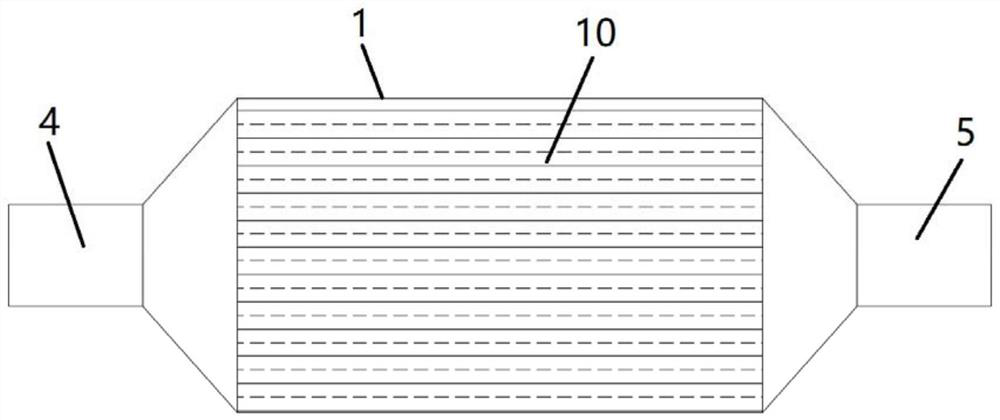

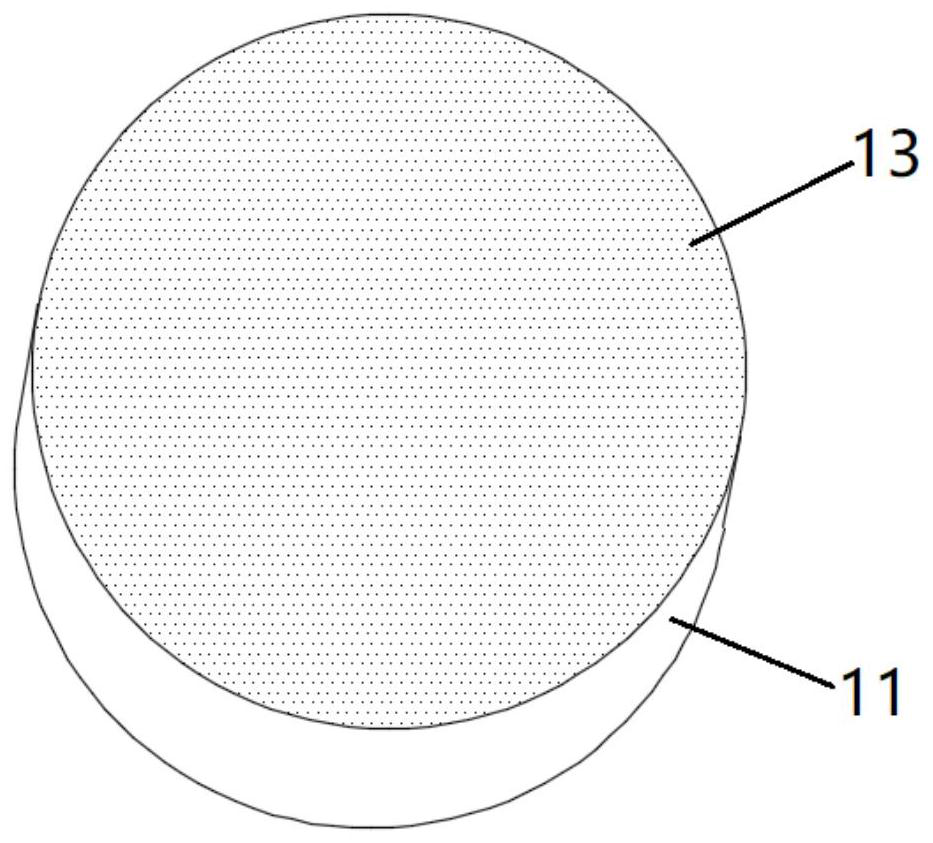

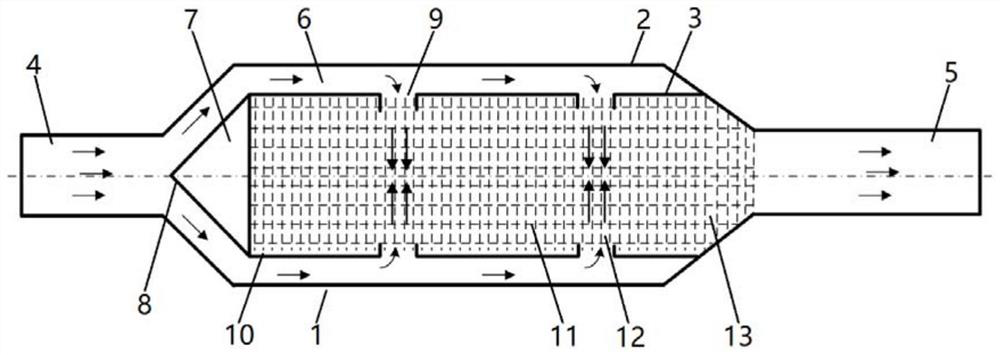

[0039] see image 3 and Figure 4 , the diesel engine exhaust particulate matter trap of this embodiment includes a trap housing that allows engine exhaust to pass through and a particulate trapping device 10 encapsulated in the trap housing, wherein the trap housing is The double-layer housing 1 , the particle trapping device 10 is a filter element 11 with a plurality of radial openings 12 .

[0040] The shape of the trap housing is basically the same as that of a traditional trap, and its basic structure is also tapered at both ends and cylindrical in the middle. One end of the trap housing is the air inlet 4, and the other end is Airflow outlet 5, the exhaust airflow generated by exhaust gas also enters through airflow inlet 4, and after being filtered by particulate trapping device 10, it is discharged from airflow outlet 5. The design of this structure upgrades the existing traditional traps on the market Because the trap of the present invention does not need to carry ...

Embodiment 2

[0051] Image 6 is a flow chart of the method for capturing particulate matter in diesel engine exhaust in the embodiment of the present invention, please refer to Image 6 As shown, the method of this embodiment is applied to the diesel exhaust particulate matter trap of Embodiment 1.

[0052] The method for capturing diesel exhaust particulate matter in this embodiment includes the following steps:

[0053] When the exhaust gas in the airflow inlet 4 passes through the particle trapping device 10 in the collector housing, the axially flowing airflow is changed to the radially flowing airflow by using the oppositely arranged counter-punching holes 9, and radial hedging occurs. The collision produces a condensation effect, and the two columns of particles collide with each other due to the collision of the gas-solid two-phase air flow, reverse phase infiltration, and settle and trap the particles.

[0054] The change of the axial flow air flow to the radial flow air flow can...

Embodiment 3

[0057] The embodiment of the present invention is basically the same as the embodiment 1, and the difference lies in that an automobile according to the embodiment of the present invention includes a diesel engine. The diesel engine is a kind of engine. The collector is the diesel exhaust particulate matter collector provided in Example 1.

[0058] When the diesel engine of the automobile is started, the exhaust gas generated by the exhaust pipe of the diesel engine is discharged into the diesel engine exhaust particulate matter trap in Example 1 of the present invention, so that the exhaust gas flowing in the axial direction of the diesel engine is split and generated along the counter-punching hole 9 The radial hedging collision produces a condensation effect, which can reduce the speed of the exhaust gas flow in the trap, prolong the trapping time, and improve the trapping rate for the sedimentation and trapping of particulate matter; the two-phase airflow hedging with exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com