A built-in block anaerobic reactor for organic wastewater

An anaerobic reactor and organic wastewater technology, applied in the field of water treatment, can solve the problems of difficulty in proliferation, poor dominance of sludge flora, poor hydrolysis effect, etc., and achieve the effect of improving reaction efficiency and reaction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

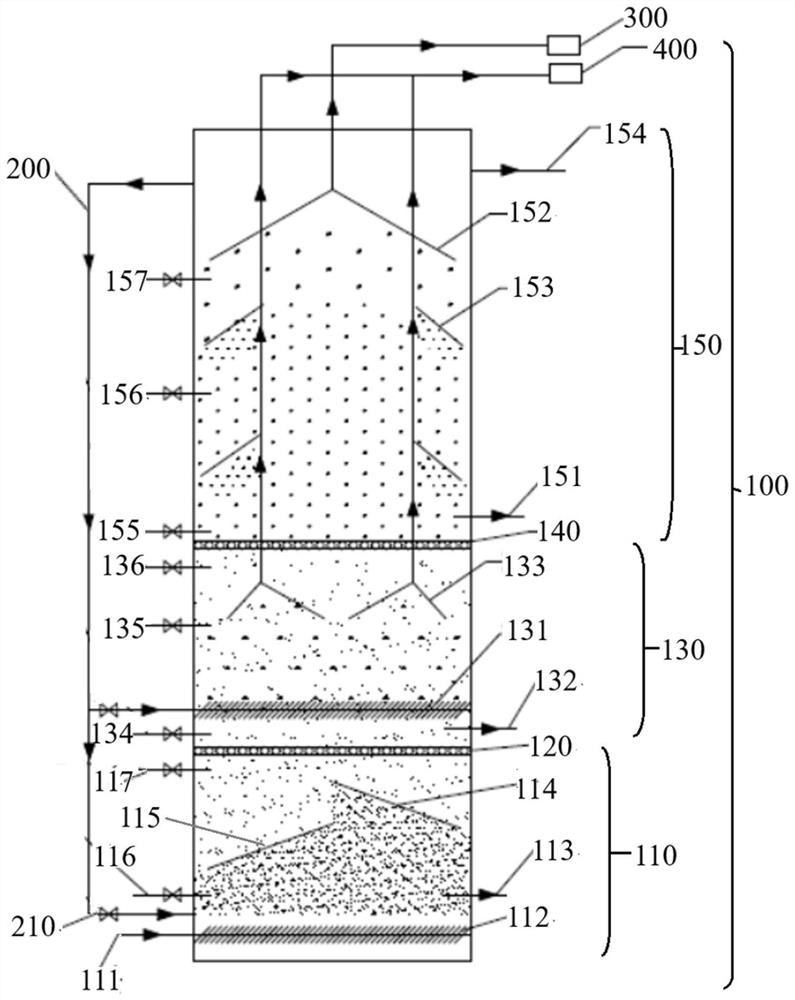

[0060] Such as figure 1 As shown, in this embodiment, the above-mentioned high-concentration organic wastewater built-in block anaerobic reactor is used to treat the wastewater in the fermentation pharmaceutical industry, and the treated water volume is 100m 3 / d, the total residence time is 24h, and the influent and effluent water quality are shown in Table 1 below.

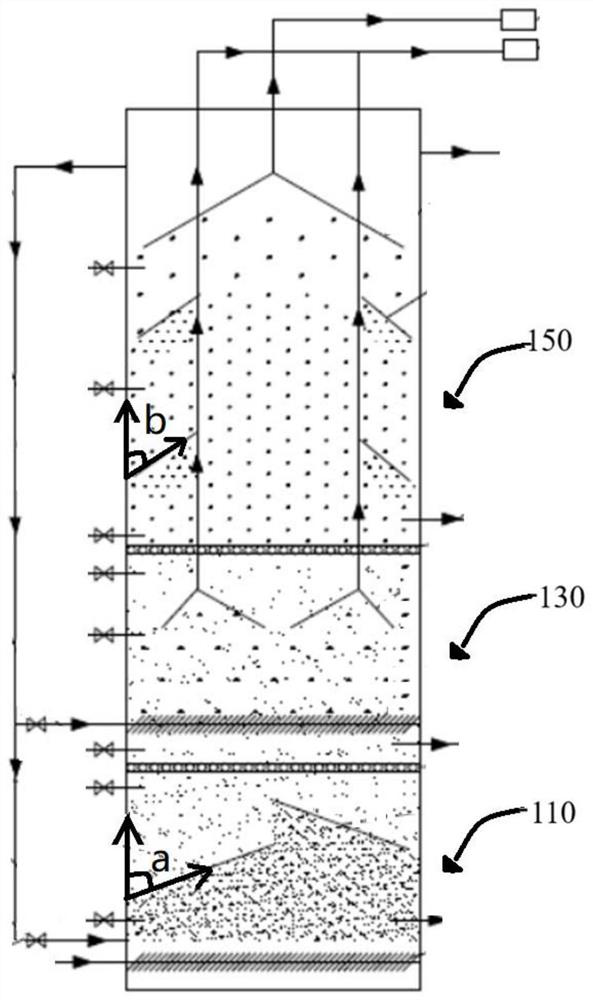

[0061] In the reactor 100 in this embodiment, a flocculent sludge zone 110, a transition zone 130, and a granular sludge zone 150 are arranged inside the reactor 100. The bottom of the flocculent sludge zone 110 is provided with a bottom water distributor 112, and the bottom of the transition zone 130 is provided with a transition zone. Water distributor 131 in the transition zone. The effluent from the upper part of the granular sludge area 150 can be optionally returned to the flocculent sludge area 110 and / or the transition area 130 through the circulation pipe 200; the transition area 130 is provided with t...

Embodiment 2

[0076] In this embodiment, the reactor 100 mainly treats the high-sugar wastewater produced in the food processing industry, the initial COD concentration is 20000mg / L, and the treated water volume is 50m 3 / d for a total residence time of 36 hours.

[0077] The high-concentration organic wastewater built-in block anaerobic reactor structure in this embodiment is basically the same as that of Embodiment 1, the only difference is that the effective volume of the reactor 100 is 75m 3 . The diameter of the designed reactor 100 is 3.5m, the effective height is 8m, and the total height is 10m. The effective height of the flocculent sludge zone 110 is 1.5m, the effective height of the transition zone 130 is 1m, and the effective height of the granular sludge zone 150 is 7.5m. The amount of water returned from the circulation pipeline 200 to the flocculent sludge area 110 is 2.1m 3 / h, the amount of water flowing back to the transition zone 130 is 37.5m 3 / h.

[0078] Such as ...

Embodiment 3

[0090] In this embodiment, the reactor 100 mainly treats wastewater from the biological fermentation industry, and the treated water volume is 600m 3 / d, which is 25m 3 / h, the initial COD concentration is 8050mg / L, and the total residence time is 20h.

[0091] The structure of the high-concentration organic wastewater built-in block anaerobic reactor in this embodiment is basically the same as in Embodiment 1, the only difference is that the effective volume of the reactor 100 is 500m 3 . The diameter of the designed reactor 100 is 7m, the effective height is 13m, and the total height is 15m. The effective height of the flocculent sludge zone 110 is 3m, the effective height of the transition zone 130 is 2m, and the effective height of the granular sludge zone 150 is 10m. The amount of water flowing back from the circulation pipeline 200 to the transition zone 130 is 150m 3 / h, the circulation pipeline 200 no longer returns to the flocculent sludge zone 130.

[0092] Such...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com