Lattice distributing type anode platform columns obtained by electroreduction metal deposition

A distributed, anode technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of slow processing speed, unsatisfactory efficiency, complex printing equipment, etc., and achieve the effect of high work efficiency, compact and reasonable structure and layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

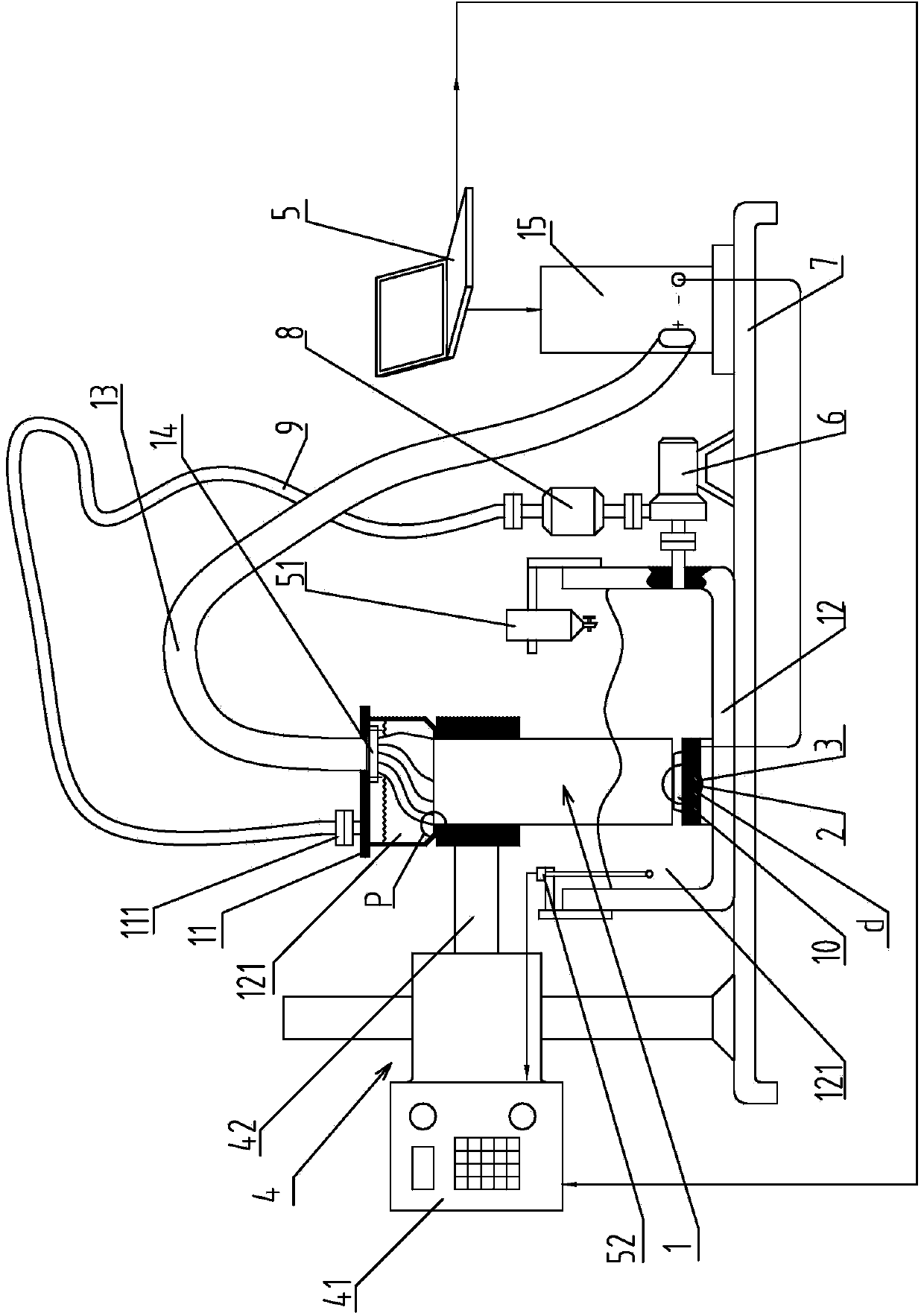

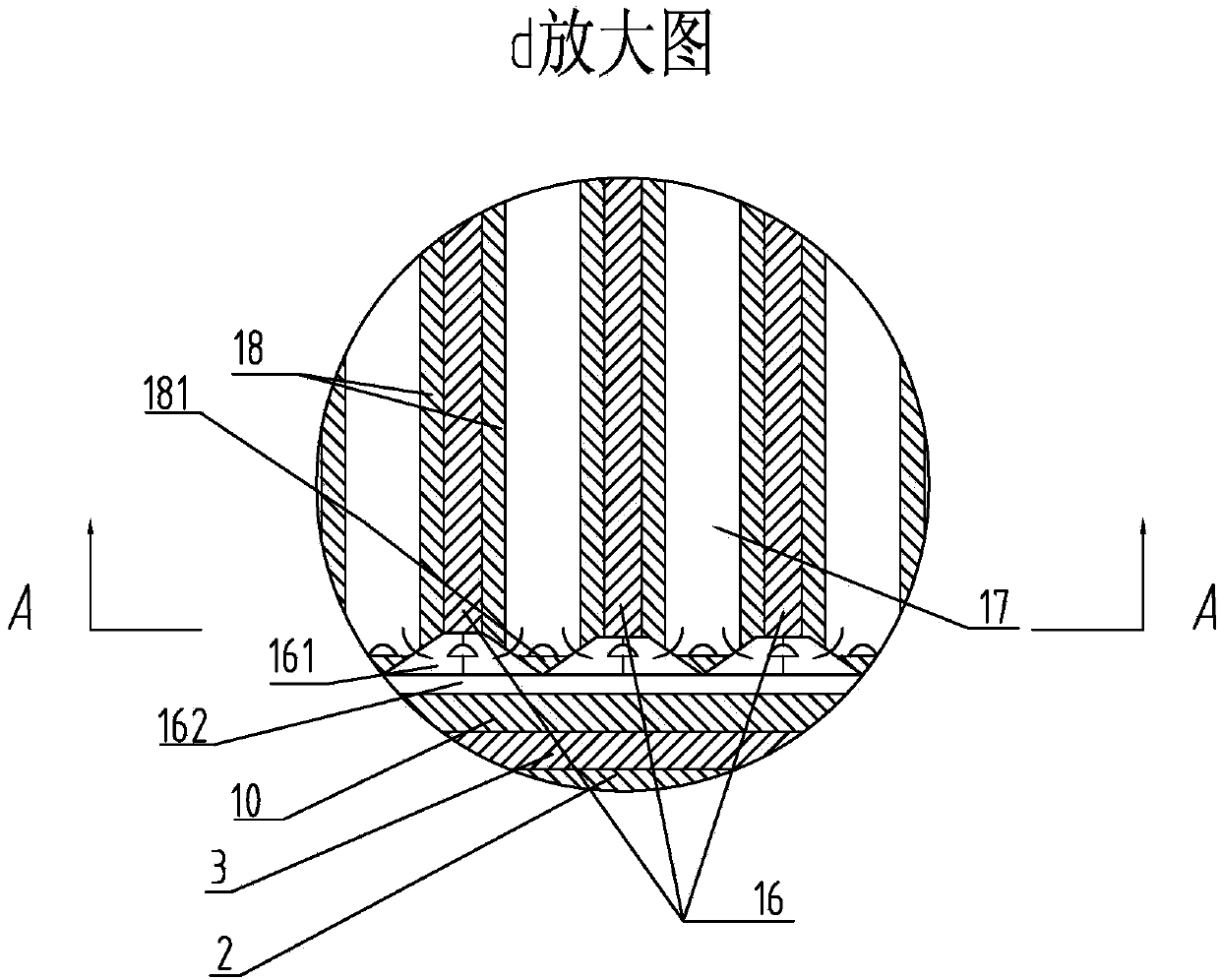

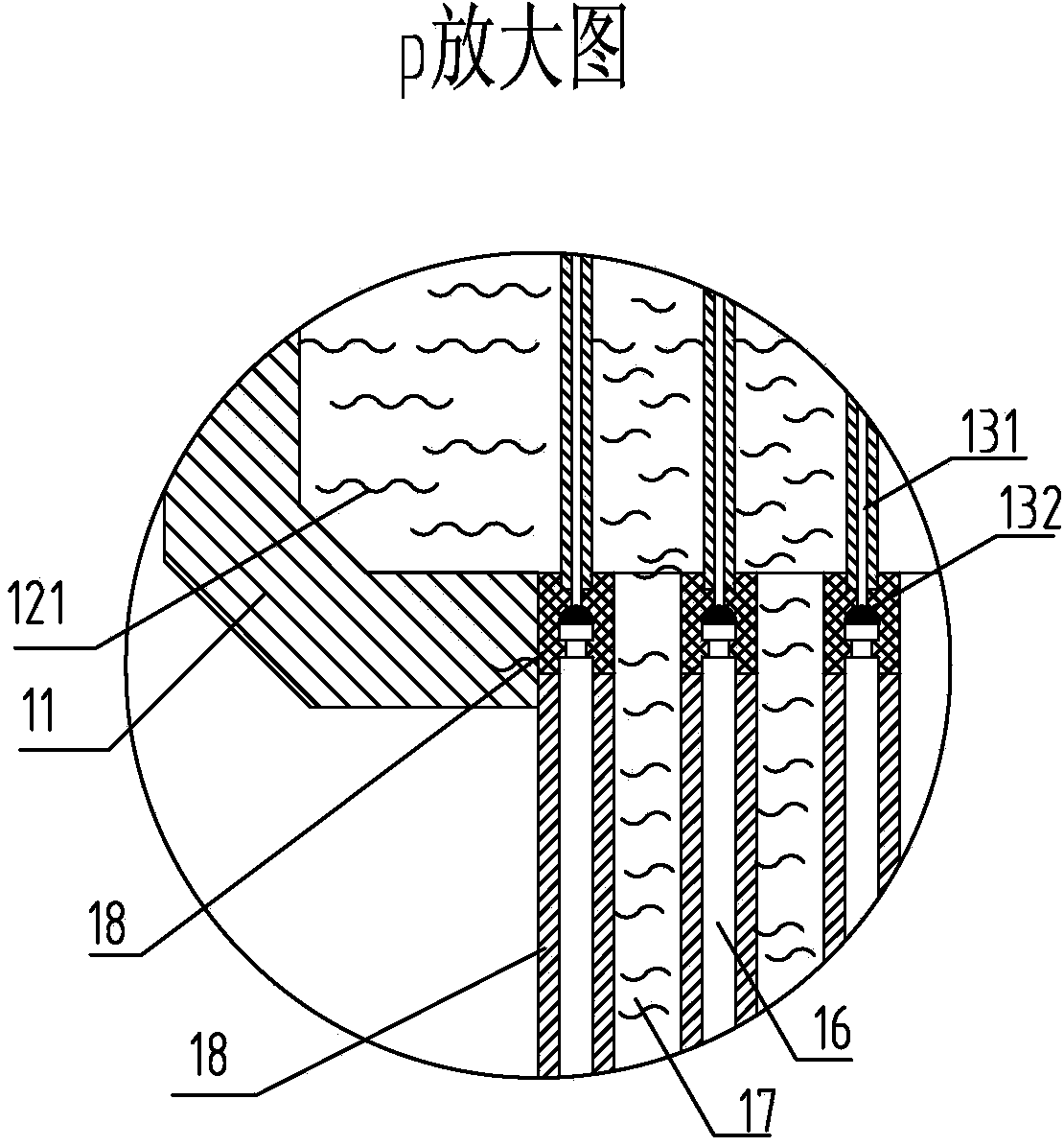

[0023]As shown in the figure, the application equipment related to the embodiment of the present invention, that is, the lattice anode electroreduction metal deposition parts 3D printing equipment includes a computer numerical control system 5, an equipment base 7, an anode numerical control vertical lifting mechanism 4, and an electrodeposition system. The electrodeposition system includes an anode 16, a metal ion solution working tank 12, an electrochemical power supply 151, a circulation pump 6, a filter 8, a cathode 2, and a working substrate 3 that forms a conductive connection during operation. Wherein metal ion solution 121, metal ion solution working tank 12, metal ion solution delivery tank 11, metal ion solution circulating pump 6, pressure delivery pipe 9 and filter 8 are also used as metal ion solution delivery under pressure The device transports the metal ion solution to the anode infusion channels 17 distributed in dot matrix. In addition, it is also possible to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com