Composite large-diameter monofilament with variable cross section and skin core structure as well as manufacturing method and application thereof

A composite monofilament, skin-core structure technology, applied in the direction of conjugated synthetic polymer rayon, filament/thread forming, textile and paper making, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

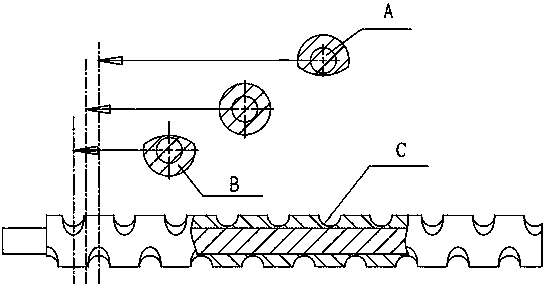

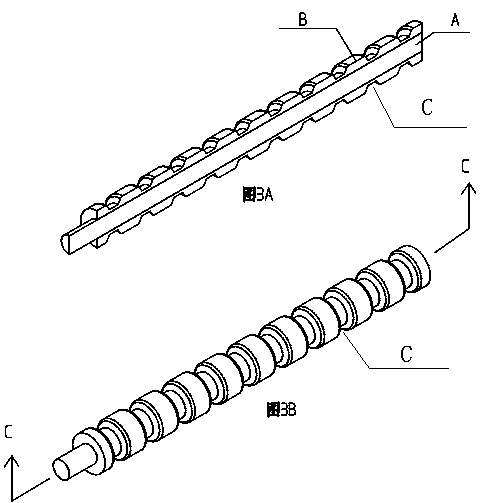

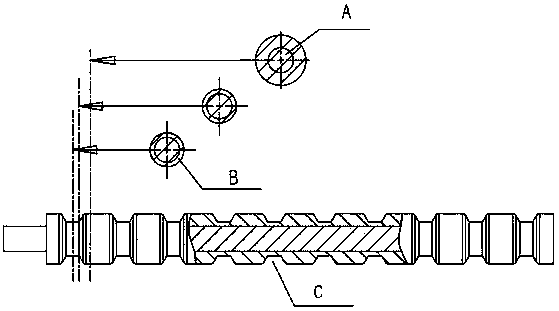

[0040] In order to describe in detail the technical content, structural features, achieved objectives and effects of the present invention, the following is a detailed description in conjunction with the embodiments and accompanying drawings.

[0041] The composite monofilament with a large diameter skin-core structure with varying cross-sections, the core of the composite monofilament is a pre-drawn polyester (PET) resin monofilament with a draft ratio of 2-6 times. The outer part of the core is uniformly covered with a thermoplastic resin skin layer, and the radial cross-sectional area of the monofilament changes periodically.

[0042] The high tensile strength of polyester (PET) resin monofilament enables the composite monofilament to have higher tensile strength and provide basic mechanical properties for the monofilament. The outer thermoplastic resin coating layer gives the composite filament the required chemical resistance , Hydrolysis resistance or other unique propertie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com