Preparation method of novel water-proof, mildew-proof, fragrant and shading door curtain fabric

A mildew-proof and fragrant technology, applied in the field of textile fabrics, can solve the problems of hard feel, no sound insulation, poor environmental protection performance, etc., and achieve the effect of improving shading performance and increasing tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

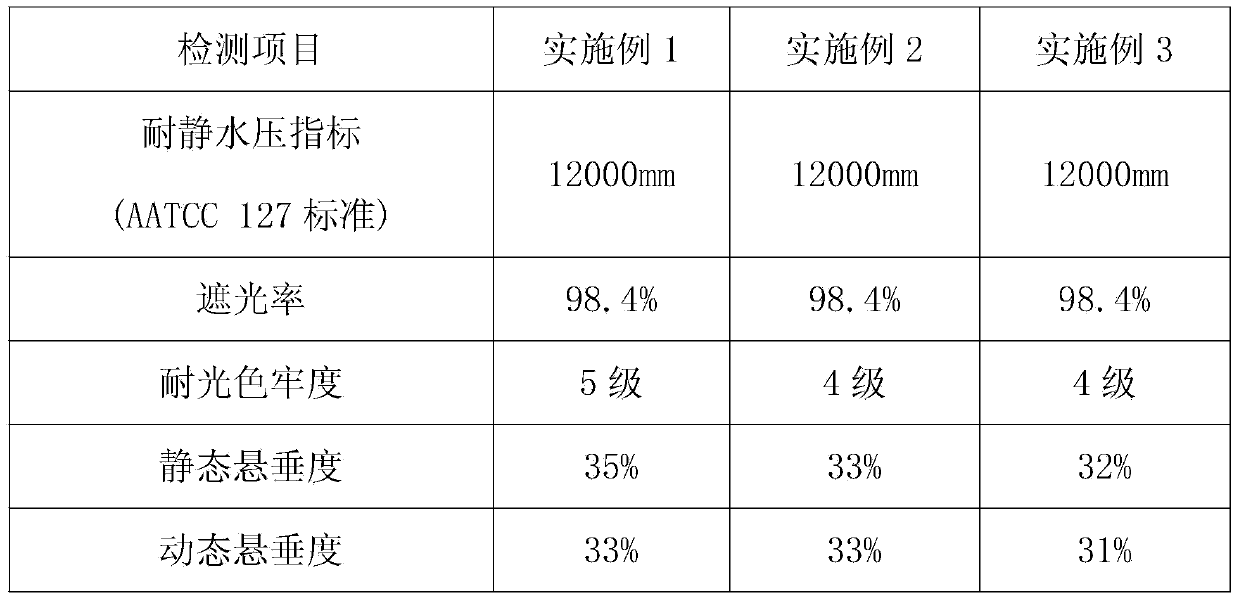

Embodiment 1

[0050] A method for preparing a novel waterproof, mildew-proof, aromatic blackout door curtain fabric, comprising the following steps:

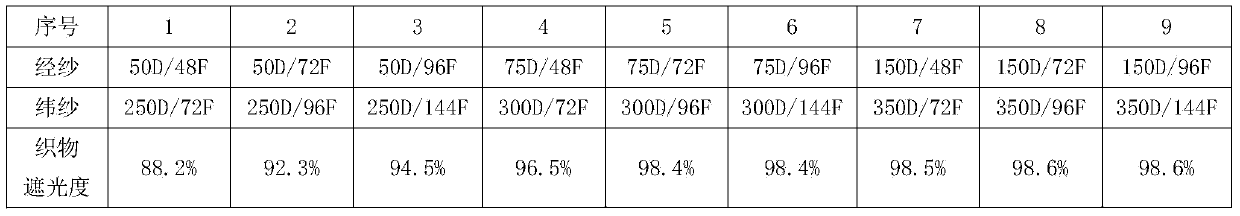

[0051] A. Weaving: Use polyester matte low-elasticity yarn as the warp yarn, and weft yarn is made of polyester low-elasticity black silk raw material. The fabric design adopts double weave, eight pieces of satin, and uses a water-jet loom to make gray cloth; Warp polyester matte low elastic yarn is 75D / 72F, weft polyester low elastic black yarn is 300D / 96F, and the machine density is 800 * 320 / 10cm;

[0052] B, sizing and oiling: the greige cloth prepared in step A is subjected to sizing and oiling treatment; the sizing uses chemical slurry PVA1799;

[0053] C. Desizing and refining: use a low bath ratio high-pressure jet overflow machine for desizing and refining treatment. The process prescription and conditions are as follows: the pH value of the desizing bath is 10, the oxidative desizing agent TF-127A: 3g / L, and a strong degreasing ag...

Embodiment 2

[0060] A method for preparing a novel waterproof, mildew-proof, aromatic blackout door curtain fabric, comprising the following steps:

[0061] A. Weaving: Use polyester matte low-elasticity yarn as the warp yarn, and weft yarn is made of polyester low-elasticity black silk raw material. The fabric design adopts double weave, eight pieces of satin, and uses a water-jet loom to make gray cloth; Warp polyester matte low elastic yarn is 75D / 72F, weft polyester low elastic black yarn is 300D / 96F, and the machine density is 800 * 320 / 10cm;

[0062] B, sizing and oiling: the greige cloth prepared in step A is subjected to sizing and oiling treatment; the sizing uses chemical slurry PVA1799;

[0063] C. Desizing and refining: use low liquor ratio high pressure jet overflow machine for desizing and refining treatment, the process prescription and conditions are as follows: desizing bath PH value 11, oxidation desizing agent TF-127A: 2g / L, strong degreasing agent TF-1158: 3g / L, NaOH...

Embodiment 3

[0070] A method for preparing a novel waterproof, mildew-proof, aromatic blackout door curtain fabric, comprising the following steps:

[0071] A. Weaving: Use polyester matte low-elasticity yarn as warp yarn, weft yarn is polyester low-elasticity black silk raw material, fabric design adopts warp double weave, adopts eight satin weaves, and uses water jet loom to make gray cloth; Warp polyester matte low elastic yarn is 75D / 72F, weft polyester low elastic black yarn is 300D / 96F, and the machine density is 800 * 320 / 10cm;

[0072] B, sizing and oiling: the greige cloth prepared in step A is subjected to sizing and oiling treatment; the sizing uses chemical slurry PVA1799;

[0073] C. Desizing and refining: use low liquor ratio high pressure jet overflow machine for desizing and refining treatment, the process prescription and conditions are as follows: desizing bath PH value 10.5, oxidation desizing agent TF-127A: 1g / L, strong degreasing agent TF-1158: 1g / L, NaOH: 2%, liquo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com