Heat pipe heat transfer system at low-temperature end of low-temperature refrigerator

A low-temperature refrigerator and heat transfer system technology, applied in the field of heat pipe heat transfer system, can solve the problems of fan motor bearing oil lubrication failure, large heat leakage of low-temperature refrigerator box, complex structure, etc., to eliminate the risk of clogging, reduce weight, The effect of efficient heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

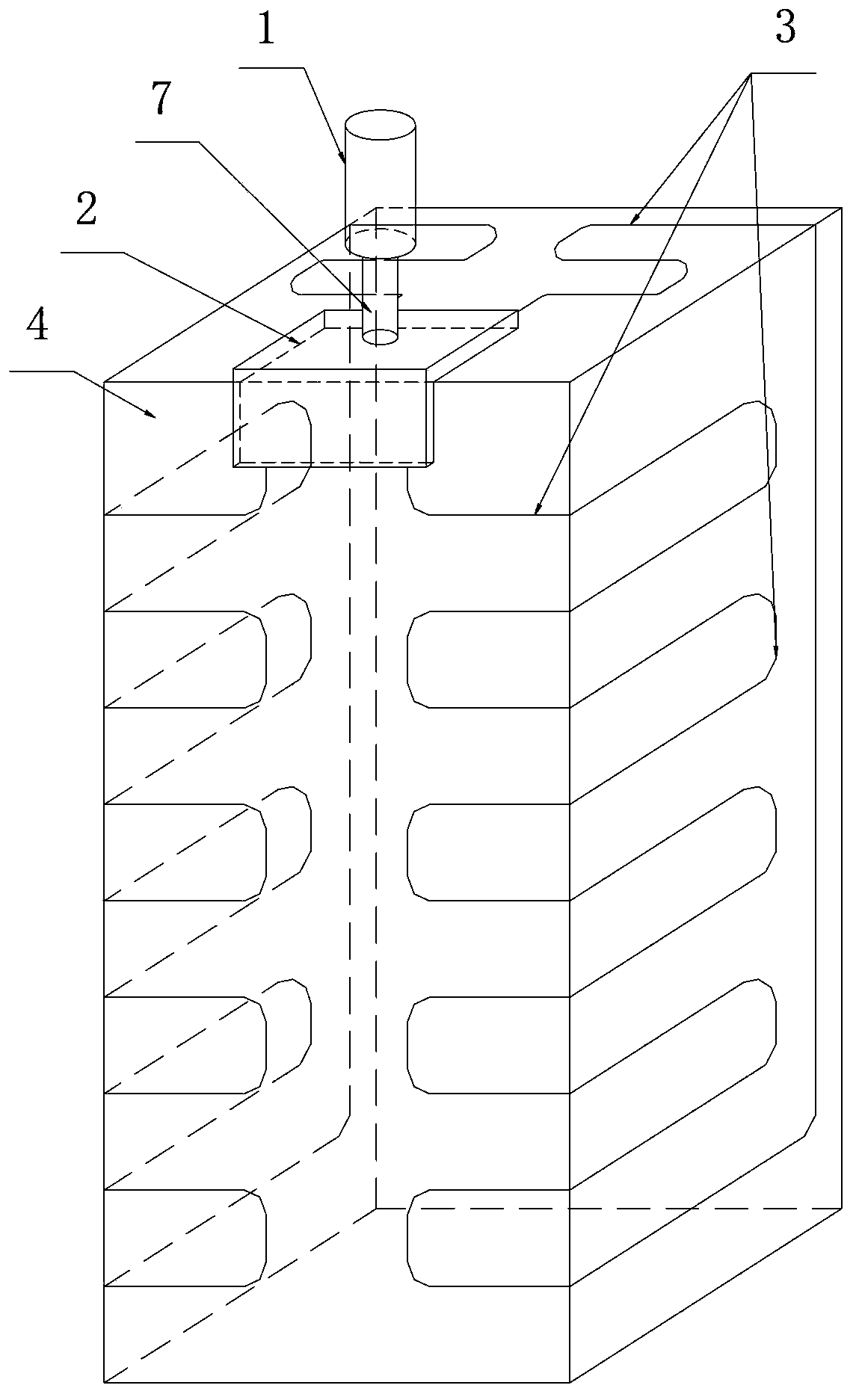

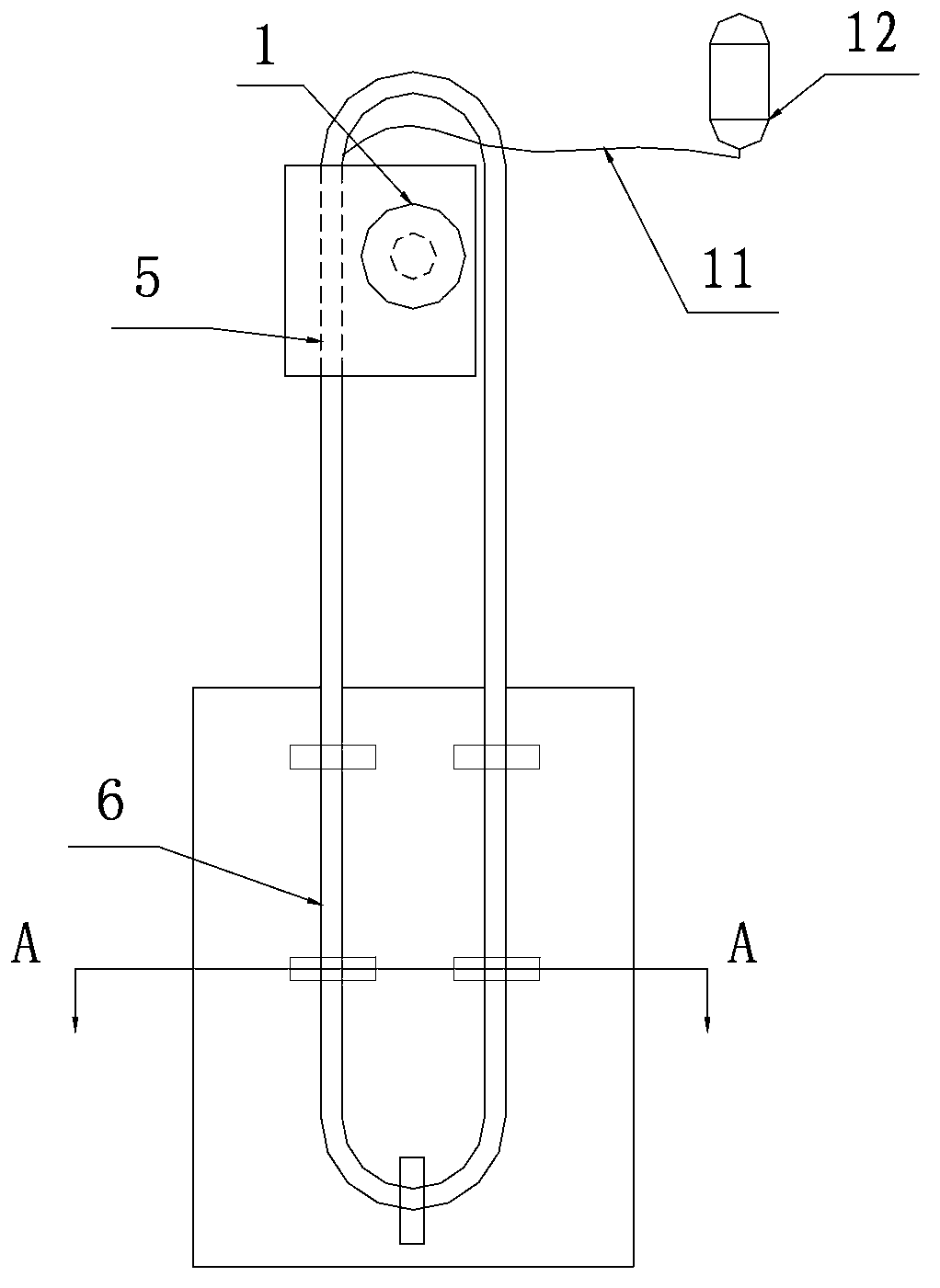

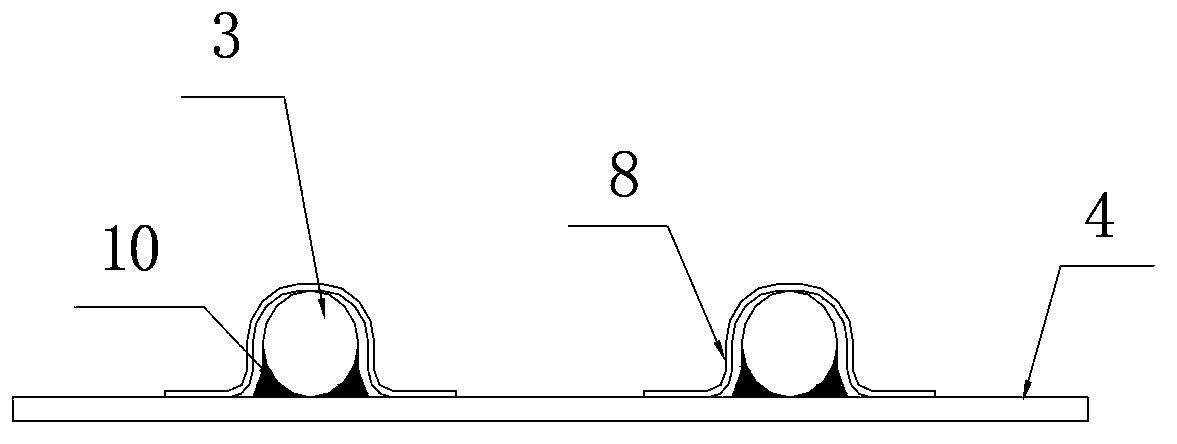

[0045] Such as figure 1 As shown, the heat exchange block 2 in this embodiment is connected to two heat pipes 3, and the two heat pipes 3 are evenly distributed on the inner container 4 of the low-temperature refrigerator. The condensation section 5 of each heat pipe 3 is connected to the heat exchange block 2, and each The evaporating section 6 of the heat pipe 3 is connected with the liner 4 of the low-temperature refrigerator.

Embodiment 2

[0047] In this embodiment, the heat exchange block 2 is connected to four heat pipes 3, and the four heat pipes 3 are evenly distributed on the inner container 4 of the low-temperature refrigerator, that is, one heat pipe 3 is arranged on each side of the inner container of the low-temperature refrigerator, and each heat pipe 3 The condensing section 5 of each heat pipe 3 is connected with the heat exchange block 2, and the evaporating section 6 of each heat pipe 3 is connected with the inner container 4 of the low-temperature refrigerator. In this way, the 90-degree corners of the heat pipe 3 can be reduced, and the processing technology is simple.

Embodiment 3

[0049] In this embodiment, the inner tank of the low-temperature refrigerator has a larger size, and the number of heat pipes 3 will be more. However, the density between the heat pipes should be controlled. Generally, the distance should be around 60mm or 100mm or 120mm. It is preferable to set them symmetrically to ensure heat exchange efficiency and balance heat exchange in all directions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com