Preparation method and application of single ion conductor nano-particle reinforced lithium battery diaphragm or polymer electrolyte

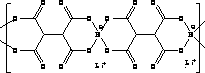

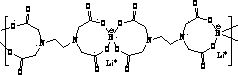

A nanoparticle and polymer technology, applied in the field of lithium battery polymer electrolyte or separator, can solve the problems of poor thermal shrinkage performance, low ionic conductivity, and no single ion conductor nanoparticle coating the electrochemical performance of lithium batteries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 100 g of single-ion conductor (polymerized pentaerythritol borate lithium salt), 50 g of polyvinylidene fluoride dissolved in 2000 g of N,N-dimethylacetamide, and mechanically grind for 3 h to obtain a uniform nano-single ion conductor. Ionic conductor / polyvinylidene fluoride hybrid paste. Take 500 g of the mixed slurry and pour it into the coating tank, use cellulose non-woven fabric as the substrate, and apply the slurry to the cellulose non-woven fabric substrate with a blade thickness of 50 μm and a tensile tension of 15 MPa. The cloth speed is 1500 mm / min, and the drying temperature is 80 °C. A battery separator or electrolyte reinforced with single ion conductor nanoparticles with a thickness of 30 μm was obtained.

Embodiment 2

[0028] Weigh 100 g of single-ion conductor (polybutyrate borate lithium salt), 80 g of polyacrylonitrile dissolved in 200 g of N,N-dimethylacetamide and 800 g of acetone, and mechanically grind for 3 h to obtain Uniform nano single ion conductor / polyacrylonitrile mixed slurry. Take 500 g of the mixed slurry and pour it into the coating tank, use polypropylene non-woven fabric as the substrate, and coat the slurry on the polypropylene substrate, the thickness of the scraper is 35 μm, the tensile tension is 30 MPa, and the coating speed is 2000 mm / min, drying temperature is 80 ℃. A battery separator or electrolyte reinforced by single ion conductor nanoparticles with a thickness of 25 μm is obtained.

Embodiment 3

[0030] Weigh 50 g of single ion conductor (lithium polytartrate borate), 50 g of polyvinylidene fluoride-hexafluoropropylene and dissolve in 500 g of N,N-dimethylformamide and 500 g of N-methylpyrrolidone , after mechanical grinding for 3 h, a uniform nano-single ion conductor / polyvinylidene fluoride-hexafluoropropylene mixed slurry was obtained. Take 500 g of the mixed slurry and pour it into the coating tank, use the polyester non-woven fabric as the substrate, and apply the slurry to the polyester non-woven fabric substrate with a scraper thickness of 40 μm and a tensile tension of 10 MPa. The cloth speed is 1800 mm / min, and the drying temperature is 120 °C. A battery separator or polymer electrolyte coated with single ion conductor nanoparticles with a thickness of 30 μm was obtained. The present invention is not limited to the above embodiments, and can be prepared according to the material ratio, scraper thickness, coating speed and drying temperature to meet the produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com