Thermal regeneration method and device of activated carbon

A technology of activated carbon and thermal regeneration, applied in separation methods, filter regeneration, chemical instruments and methods, etc., can solve the problems of low utilization efficiency, low economic value, and unreasonable utilization of flue gas or waste gas heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

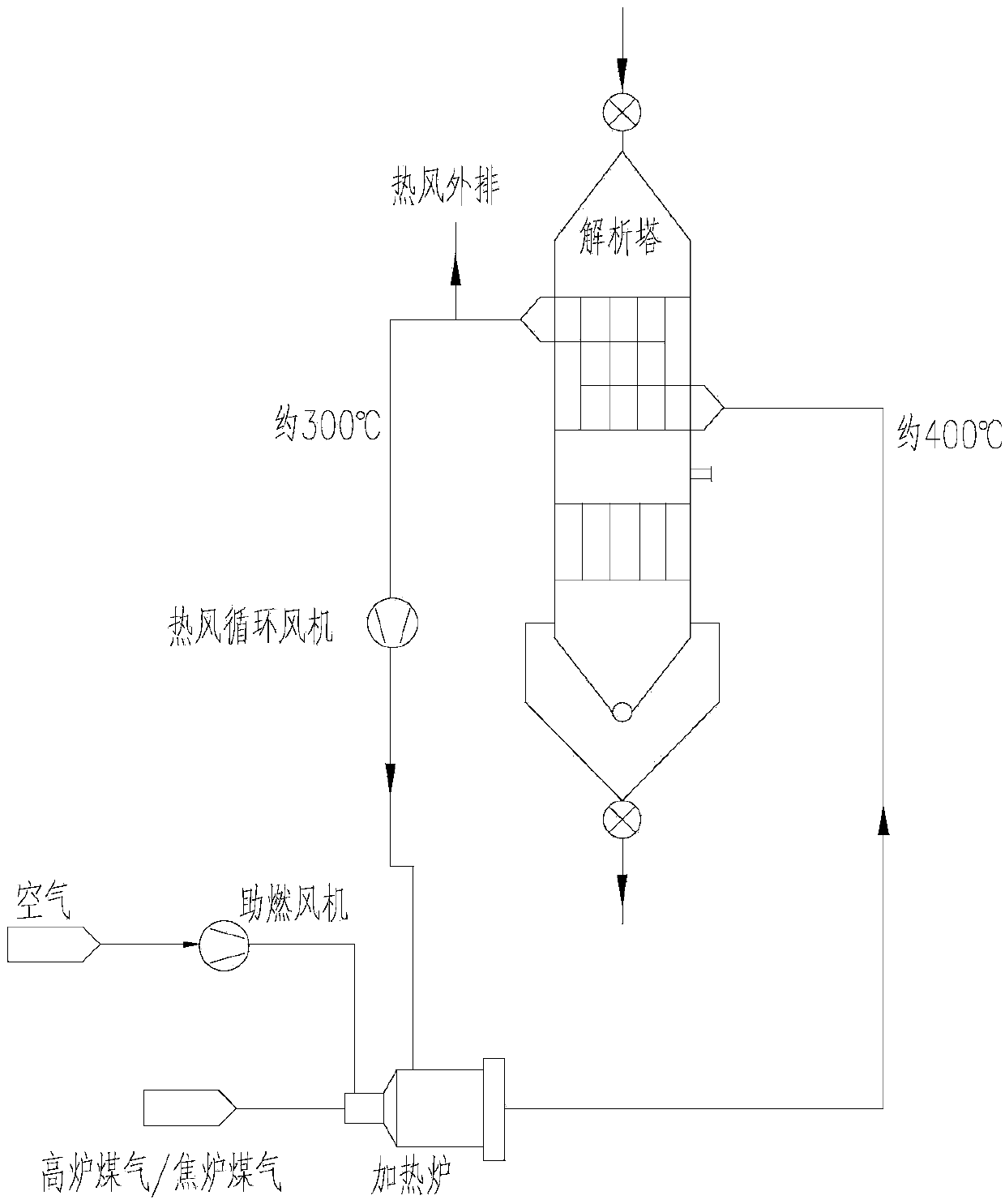

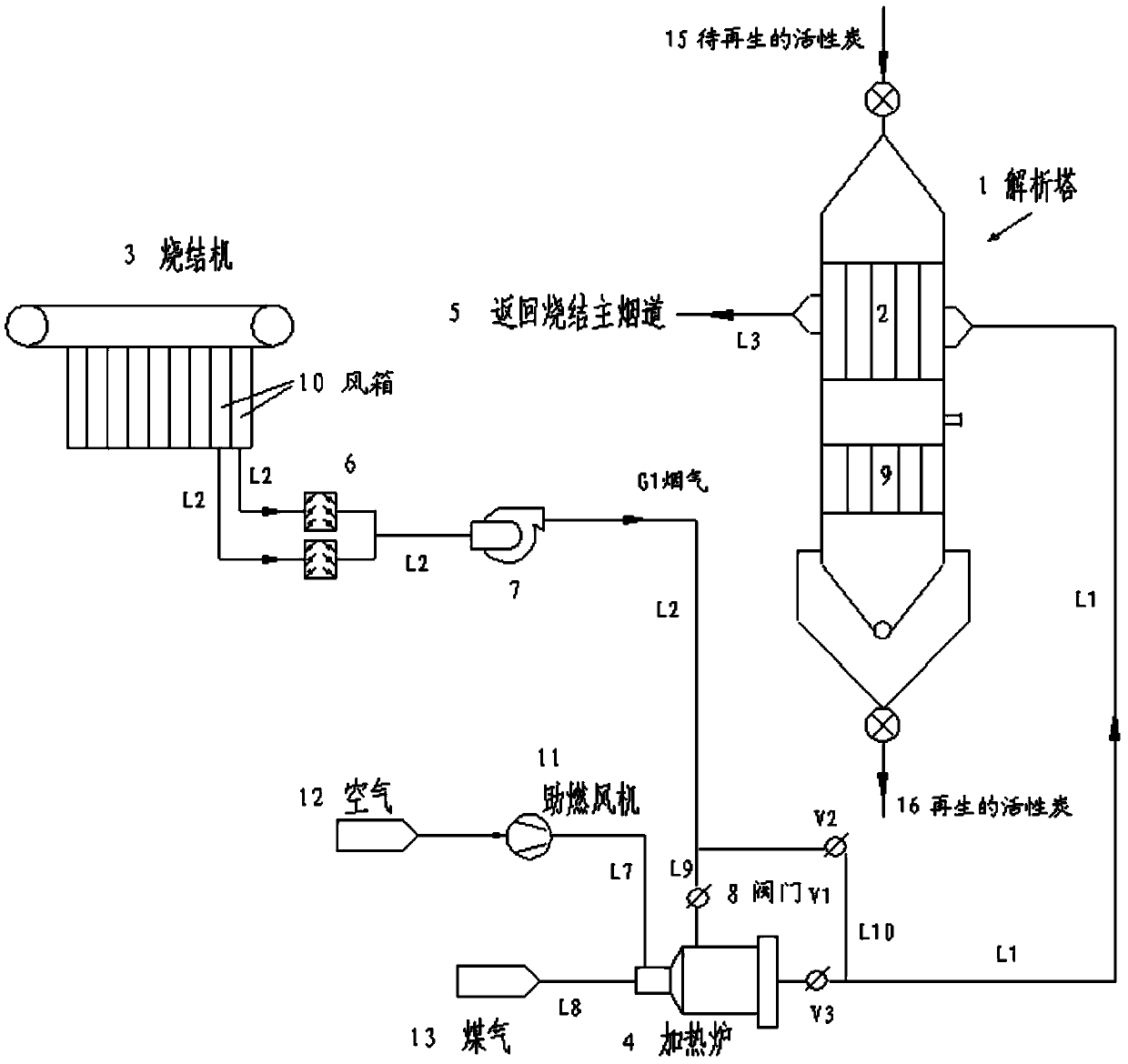

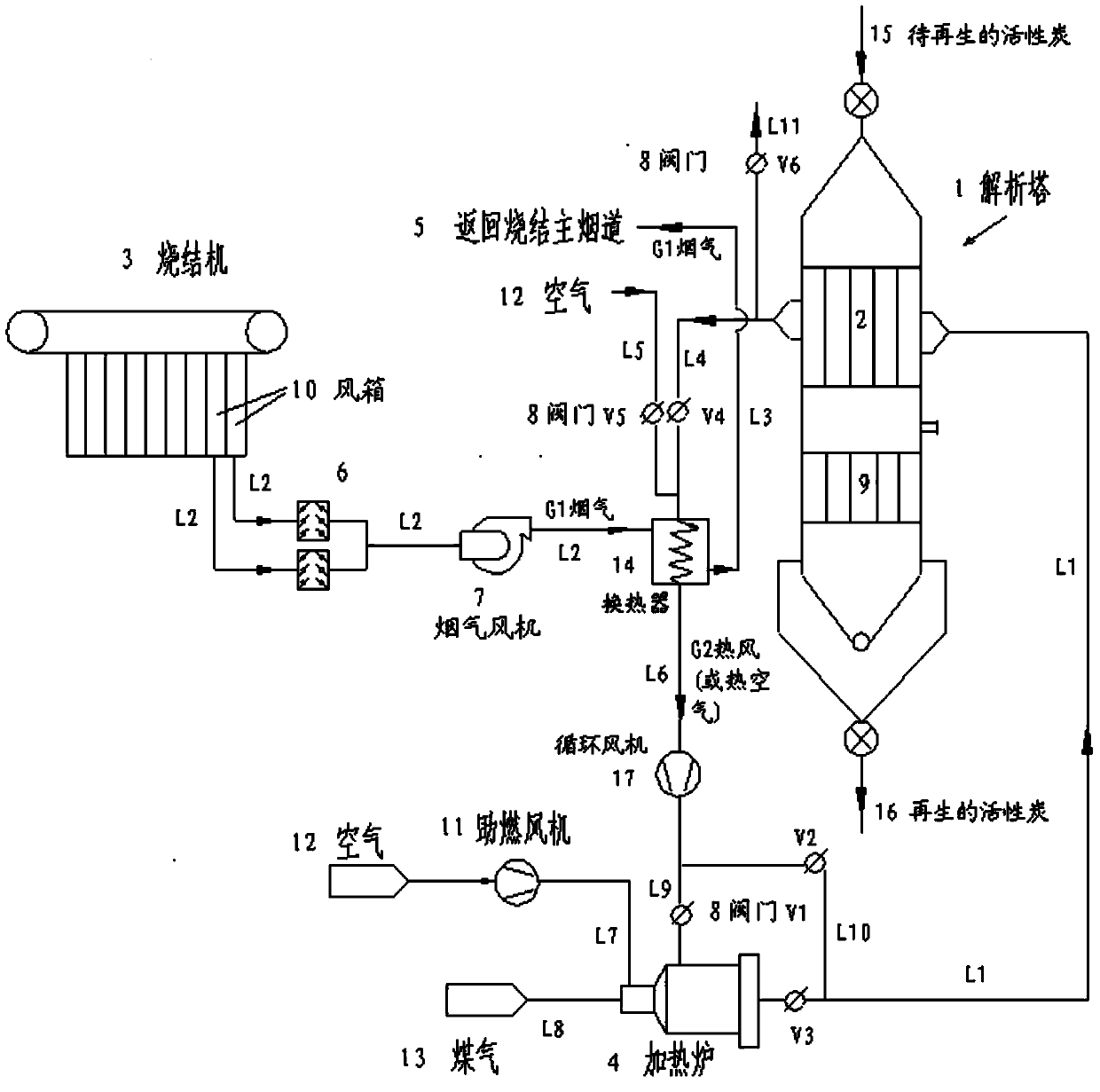

[0008] According to a first embodiment of the present invention, a kind of thermal regeneration method of activated carbon is provided, the method comprises:

[0009] 1) Transfer the activated carbon that has adsorbed pollutants including sulfur oxides, nitrogen oxides and dioxins from the flue gas or sintering flue gas in the activated carbon adsorption tower of the desulfurization and denitrification device to the activated carbon from the bottom of the adsorption tower In the heating zone of the desorption tower, the desulfurization and denitrification devices include activated carbon adsorption tower and desorption tower; and

[0010] 2) In the heating zone of the desorption tower, the activated carbon and the heating gas input into the heating zone undergo indirect heat exchange and are heated or raised to the activated carbon regeneration temperature (or activated carbon desorption temperature) T1, resulting in desorption and regeneration of the activated carbon at the T1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com