A kind of preparation method of Sn-based microporous molecular sieve Nox-Scr catalyst

A microporous molecular sieve and molecular sieve technology, applied in the fields of environmental protection and air pollution control, to achieve the effects of superior catalytic stability and excellent catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

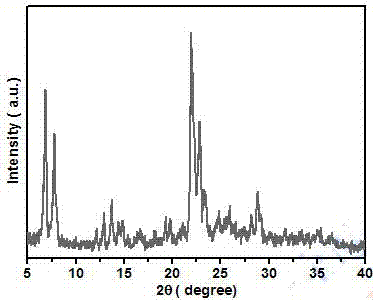

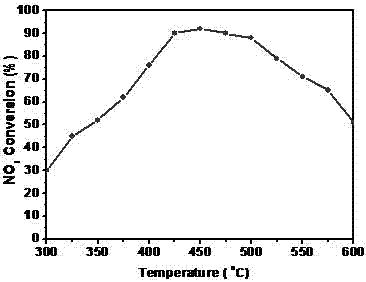

[0022] Tetraethyl orthosilicate, sodium aluminate and tin tetrachloride are used as precursors, tetrapropylammonium hydroxide is used as a template, and the reaction is carried out according to the Sn / Al molar ratio of 2:1, filtered, washed, dried, and 2 o C / min heating rate at 550 o C for 6 h to obtain the example 1 in situ synthesis method Sn-based molecular sieve catalyst sample. 0.1 g of the catalyst prepared at 550 o C under pretreatment for 30 min, then cooled to room temperature, and then 10 o The temperature is programmed at C / min rate, and a mixed reaction gas with a total flow rate of 100 ml / min is introduced, which contains 0.4% CH 4 , 0.6%NO, 6%O 2 , detection 300 – 600 o C temperature range NO x Conversion rate.

Embodiment 2

[0024] Tetraethyl orthosilicate, sodium aluminate and tin tetrachloride were used as precursors, tetrapropylammonium hydroxide was used as a template, and the reaction was carried out according to the Sn / Al molar ratio of 1:1, filtered, washed, dried, and 2 o C / min heating rate at 550 o C for 6 h to obtain the example 2 in situ synthesis method Sn-based molecular sieve catalyst sample. 0.1 g of the catalyst prepared at 550 o C under pretreatment for 30 min, then cooled to room temperature, and then 10 o The temperature is programmed at C / min rate, and a mixed reaction gas with a total flow rate of 100 ml / min is introduced, which contains 0.4% CH 4 , 0.6%NO, 6%O 2 , detection 300 – 600 o C temperature range NO x Conversion rate.

Embodiment 3

[0026] Tetraethyl orthosilicate, sodium aluminate and tin tetrachloride were used as precursors, tetrapropylammonium hydroxide was used as a template, and the reaction was carried out according to the Sn / Al molar ratio of 1:2, filtered, washed, dried, and 2 o C / min heating rate at 550 o C for 6 h to obtain the example 3 in situ synthesis method Sn-based molecular sieve catalyst sample. 0.1 g of the catalyst prepared at 550 oC under pretreatment for 30 min, then cooled to room temperature, and then 10 o The temperature is programmed at C / min rate, and a mixed reaction gas with a total flow rate of 100 ml / min is introduced, which contains 0.4% CH 4 , 0.6%NO, 6%O 2 , detection 300 – 600 o C temperature range NO x Conversion rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com