Laser cutting machine with automatic positioning function

A laser cutting machine, automatic positioning technology, applied in the field of mechanical processing and manufacturing, to achieve the effect of simple control, convenient human-machine dialogue and friendly interaction, and no cumulative error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but the content protected by the present invention is not limited to the following description.

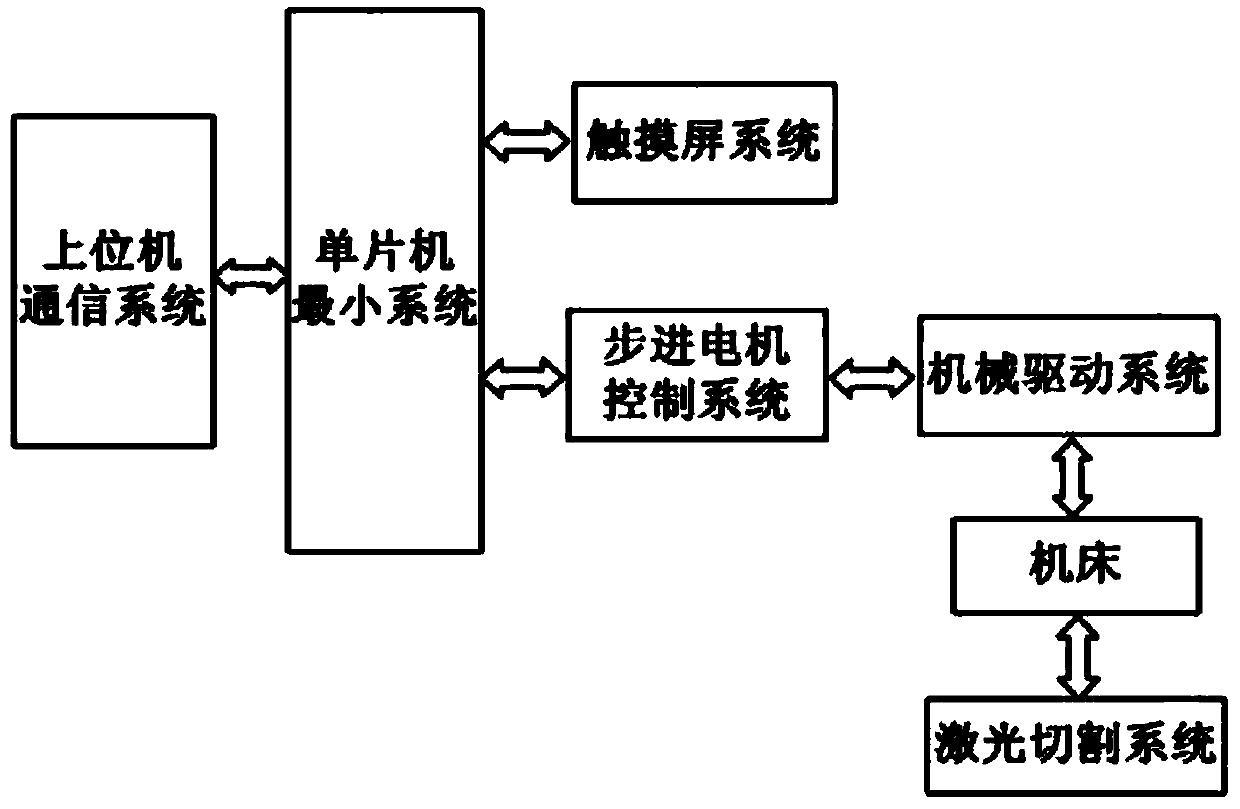

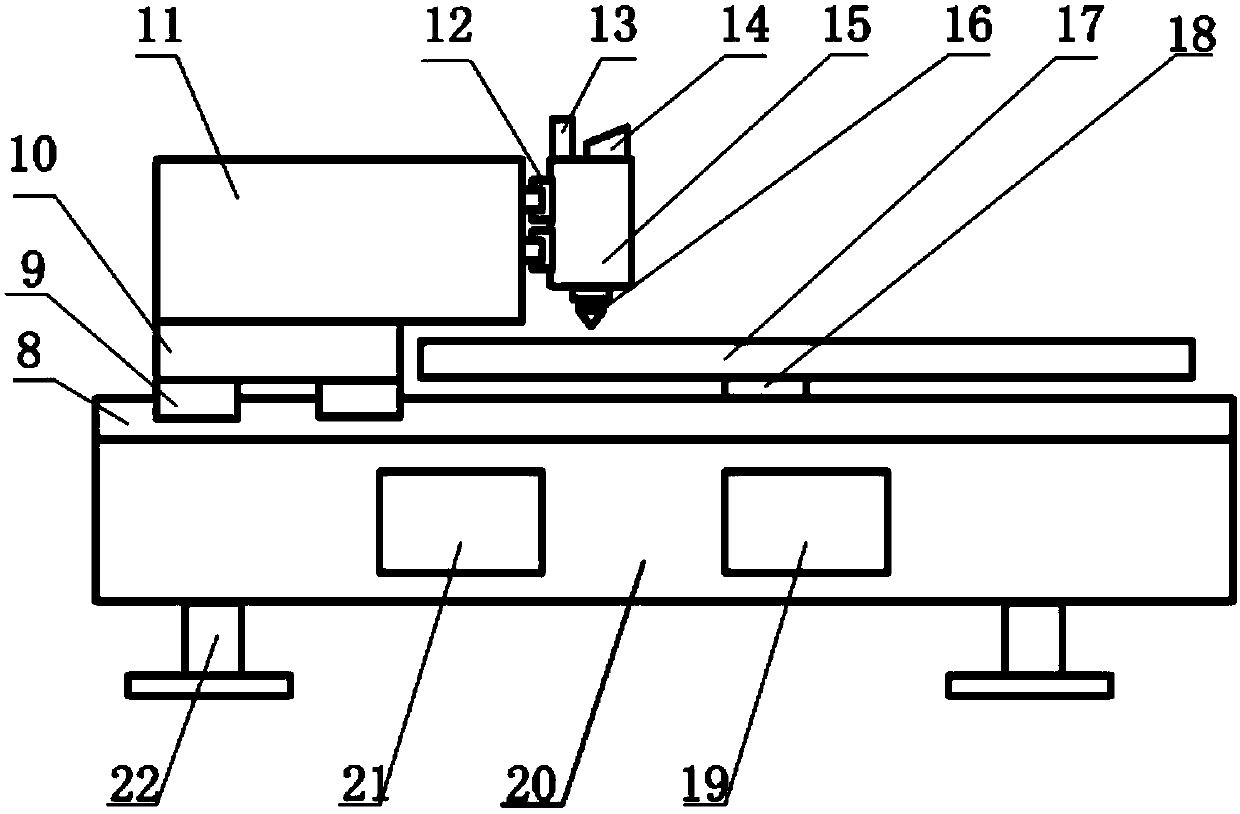

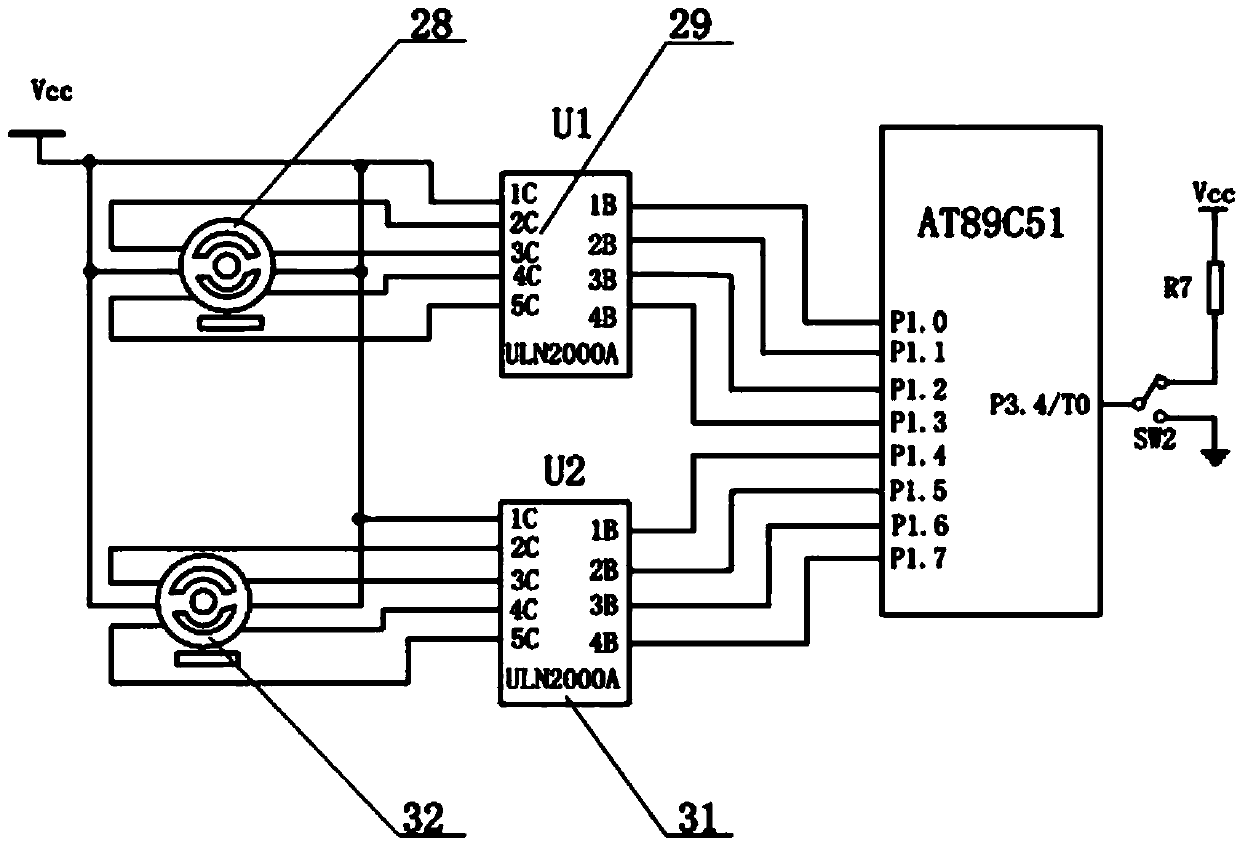

[0032] Such as figure 1 , figure 2As shown, a laser cutting machine with automatic positioning function includes a host computer communication system, a minimum single-chip microcomputer system, a touch screen system, a stepping motor control system, a mechanical drive system, a machine tool and a laser cutting machine system. The machine tool includes a machine bed 20 And the machine tool guide rail 8, the machine tool guide rail 8 is installed on the machine tool bed 20, the machine tool bed 20 is placed on the ground through the machine tool base 22, the touch screen system is installed on the touch screen console 19 of the machine tool bed 20 side, and the laser cutting system is installed on the On the bed 20 of the machine tool, the mechanic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com