Release film used for casting MLCC (Multiplayer Ceramic Chip Capacitor)

A release film and release layer technology, used in coatings, layered products, synthetic resin layered products, etc., can solve the problem of non-wetting of the release film, improve the residual adhesion rate, improve the antistatic performance, The effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

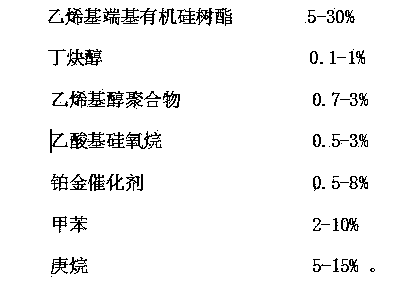

Embodiment 1

[0019] A release film for MLCC casting, comprising a film base layer and an undercoat layer, an antistatic layer and a release layer coated on the film base layer in sequence, an adhesive is coated on the undercoat layer, and an antistatic layer is coated on the base layer Anti-static liquid is coated, and release agent is coated on the release layer. The film used for the base layer of the film is PET film, and the thickness of the base layer of the film is 250um. Among them, the release agent is composed of the following components in mass percentage: 30% vinyl-terminated silicone resin, 1% butynol, 3% vinyl alcohol polymer, 3% acetoxysiloxane, platinum catalyst 8%, toluene 10%, ethyl acetate 5%, heptane 15%. The concentration of the release agent is 5%, and the thickness is 0.5 μm. The binder is polyvinyl butyral, with silica particles with a particle size of 0.1-0.2 μm inside. In order to have sufficient adhesion without affecting the haze of the film, the thickness of th...

Embodiment 2

[0021] A release film for MLCC casting, comprising a film base layer and an undercoat layer, an antistatic layer and a release layer coated on the film base layer in sequence, an adhesive is coated on the undercoat layer, and an antistatic layer is coated on the base layer Anti-static liquid is coated, and release agent is coated on the release layer. The film used for the base layer of the film is a PBT film, and the thickness of the base layer of the film is 25um. Among them, the release agent is composed of the following components in mass percentage: vinyl-terminated silicone resin 5%, butynol 0.3%, vinyl alcohol polymer 0.7%, acetate siloxane 0.5%, platinum catalyst 1.5%, toluene 2%, ethyl acetate 80%, heptane 5-15%. The concentration of the release agent is 8%, and the thickness is 0.1 μm. The binder is polyvinyl butyral, and silica particles with a particle size of 0.05 μm are added inside. In order to have sufficient adhesion without affecting the haze of the film, th...

Embodiment 3

[0023] A release film for MLCC casting, comprising a film base layer and an undercoat layer, an antistatic layer and a release layer coated on the film base layer in sequence, an adhesive is coated on the undercoat layer, and an antistatic layer is coated on the base layer Anti-static liquid is coated, and release agent is coated on the release layer. The film used for the base layer is PENT film, and the thickness of the base layer is 150um. Among them, the release agent is composed of the following components in mass percentage: vinyl-terminated silicone resin 25%, butynol 0.3%, vinyl alcohol polymer 0.7%, acetate siloxane 0.5%, platinum catalyst 1.5%, toluene 2%, ethyl acetate 80%, heptane 10%. The concentration of the release agent is 10%, and the thickness is 1.0 μm. The binder is polyvinyl butyral, with silica particles with a particle size of 0.01-0.15 μm inside. In order to have sufficient adhesion without affecting the haze of the film, the thickness of the primer la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com