Method for manufacturing release film for chip component manufacturing process and release film obtained therefrom

A manufacturing method and release film technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, coatings, etc., can solve the problem of poor adhesion between the release agent coating layer and the base film, and the release agent coating layer Large contact angle, poor surface flatness and other problems, to achieve the effect of uniform appearance, improved residual bonding rate, and low surface contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

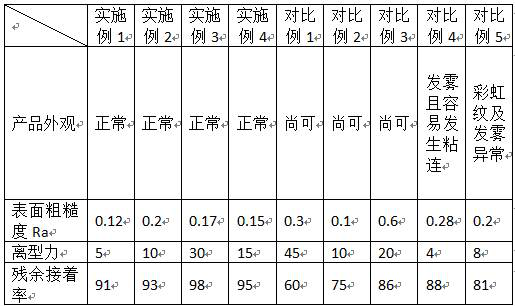

Examples

Embodiment 1

[0031] A method for manufacturing a release film for a chip component manufacturing process, comprising:

[0032] 1. Preparation of PET base film:

[0033] Add 1600ppm of additive particles with a particle size of 500~800nm in the PET chip, and the additive particles can be selected as one or more powder particles such as silicon dioxide, calcium carbonate, magnesium carbonate, barium carbonate, barium sulfate, aluminum oxide, and titanium oxide. First, magnesium carbonate is used in this embodiment, and after mixing evenly, it undergoes high-temperature melting, screw mixing, extrusion casting, stretching (horizontal stretching and longitudinal stretching), slitting and winding to obtain a base film with a thickness of 75 μm;

[0034] 2. Preparation of release agent:

[0035] Mix the components of the release agent according to the following percentages: vinyl-terminated silicone resin 15%, butynol 0.8%, silane coupling agent 0.05%, platinum complex 0.15%, solvent 84%, sti...

Embodiment 2

[0039] A method for manufacturing a release film for a chip component manufacturing process, comprising the following steps:

[0040] 1. Add 1000ppm of additive particles with a particle size of 1000~1500nm to the PET chip. The additive particles can be a mixture of silicon dioxide, barium carbonate, and titanium oxide. The mixing percentage is: silicon dioxide 80%, barium carbonate 10%, Titanium oxide 10%, mixed evenly, through melting, screw mixing, extrusion casting, stretching (horizontal stretching and longitudinal stretching), slitting and winding to obtain a release film base film with a thickness of 50 μm;

[0041] 2. Mix the components of the release agent according to the following percentages: 8% vinyl-terminated silicone resin, 0.5% butynol, 0.05% silane coupling agent, 0.25% platinum complex, 91.2% solvent, and stir Evenly, spare. Wherein, the solvent may be one or more of No. 120 solvent naphtha, butanone, D30 solvent naphtha, ethyl acetate, and isopropanol. In ...

Embodiment 3

[0044] A method for manufacturing a release film for a chip component manufacturing process, comprising the following steps:

[0045] 1. Add 1200ppm of additive particles with a particle size of 800~1200nm to the PET chip. The additive particles can be a mixture of silicon dioxide, barium carbonate and titanium oxide. The mixing percentage is: silicon dioxide 95%, barium carbonate 1%, Titanium oxide 4%, mixed evenly, through melting, screw mixing, extrusion casting, stretching (horizontal stretching and longitudinal stretching), slitting and winding to obtain a release film base film with a thickness of 25 μm;

[0046] 2. Mix the components of the release agent according to the following percentages: 2% vinyl-terminated silicone resin, 0.1% butynol, 0.5% silane coupling agent, 0.4% platinum complex, 97% solvent, and stir Evenly, spare. Among them, the solvent used in this embodiment is a mixed solvent: 30% of No. 120 mineral spirits, 22% of butanone, 15% of D30 mineral spirit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com