Sub-boiling distillation method for high-purity hydrochloric acid

A high-purity hydrochloric acid, sub-boiling distillation technology, applied in the field of sub-boiling distillation of high-purity hydrochloric acid, can solve the problem of slow distillation rate and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

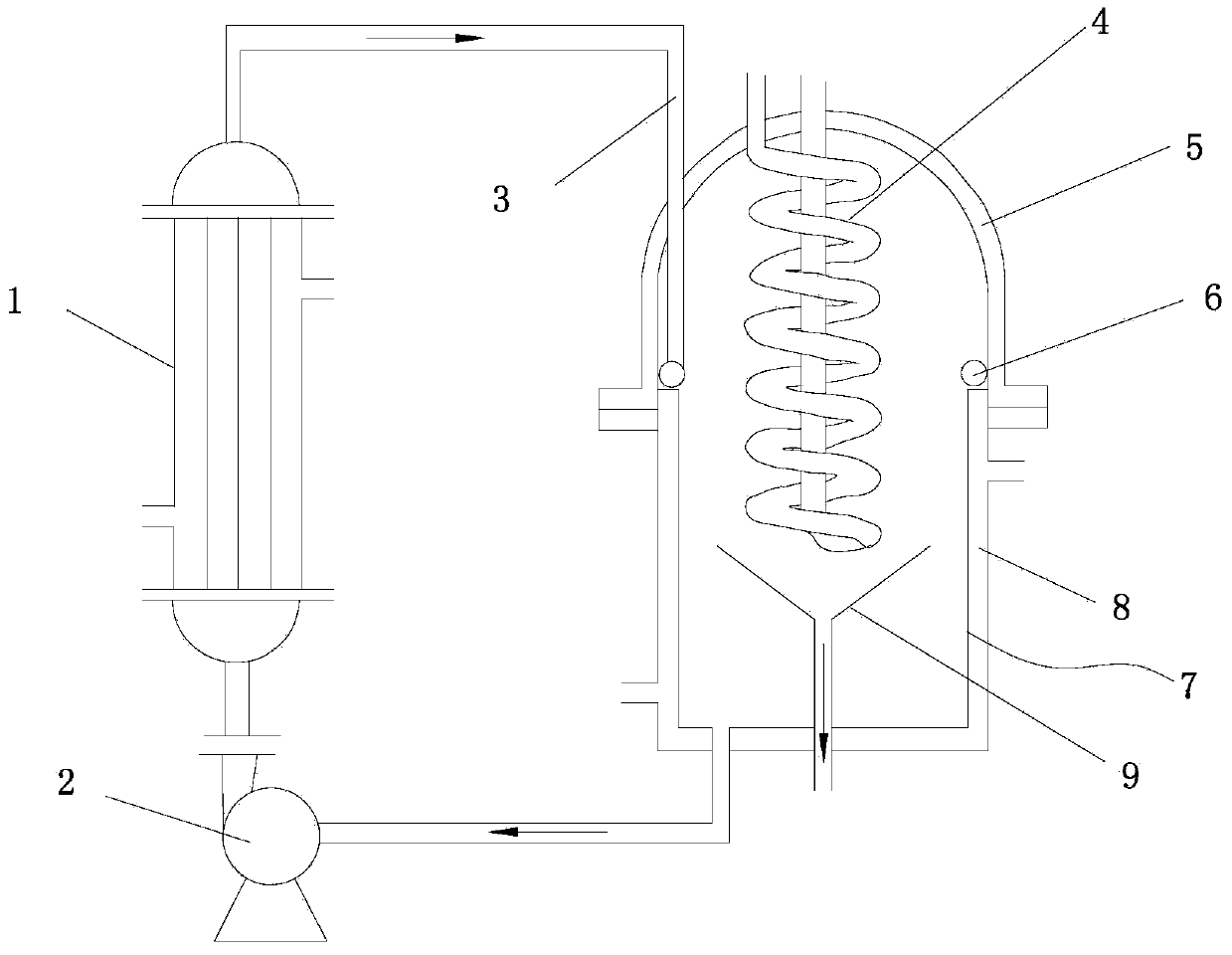

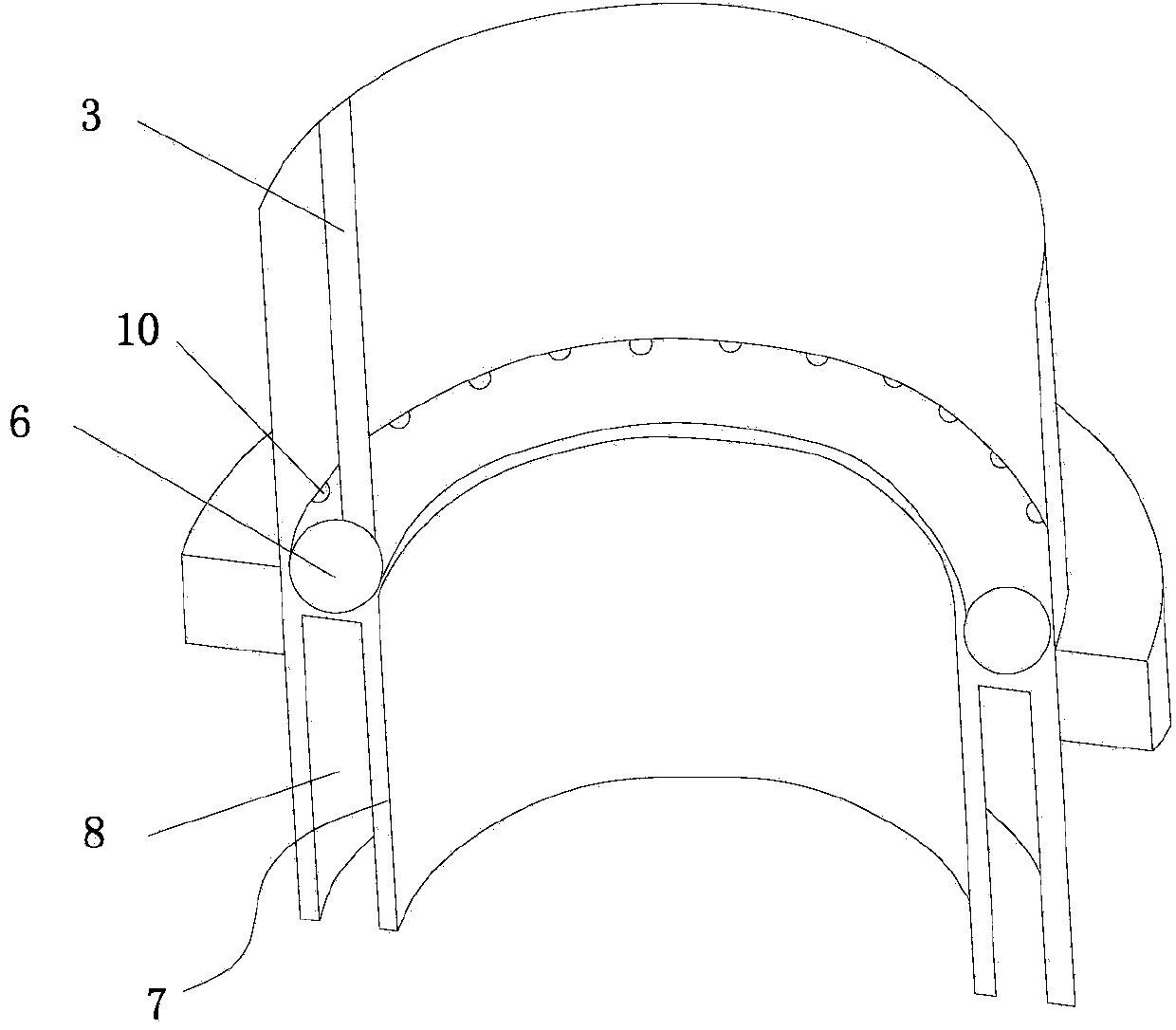

Method used

Image

Examples

Embodiment 1~7

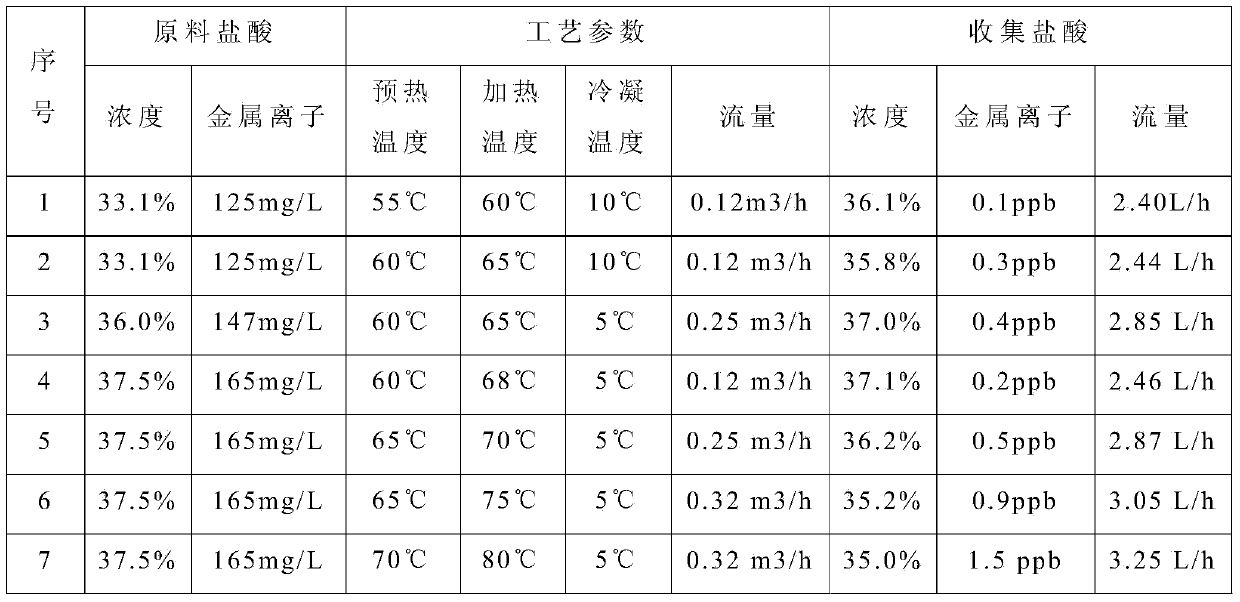

[0031] The raw material hydrochloric acid adopts the hydrochloric acid from the fluorocarbon alkane production plant, the still body 7 internal diameter D=500mm of the distiller that adopts, the height H=800mm of the heating jacket 8, the surface area of the inner side wall of the still body 7 is S=1.256m 2 , the surface area of the inner wall of the still body 7 is the evaporation area. Relevant process parameters are controlled. After a fraction is produced, the collected liquid for the first 2 hours is collected separately, and the subsequent one is used as a formal product. The relevant implementation data are shown in Table 1 below:

[0032] Table 1

[0033]

[0034] As can be seen from the data in the above table, heating temperature, condensation temperature, circulation all have greater influence on the quality and the flow rate of product hydrochloric acid, operate within the implementation process parameter of the present invention, can satisfy hydrochloric a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com