A kind of composite drinking water defluoridation method

A technology for drinking water and raw water, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., to achieve the effect of improving fluorine removal capacity, low turbidity, and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

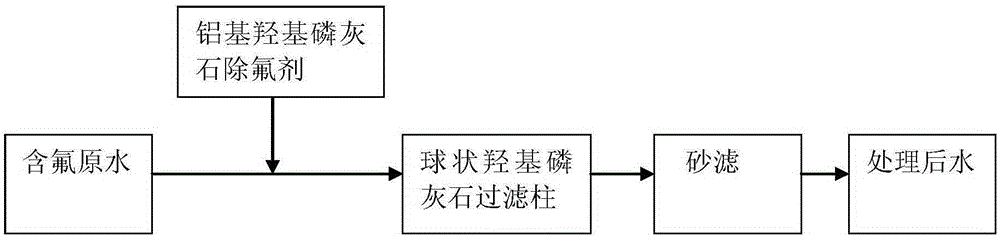

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: If the fluorine content of the raw water is 2.6 mg / L, the treatment process is as follows:

[0017] (1) Add 70ppm of compound hydroxyaluminum phosphorous ash defluoridation agent to the water inlet;

[0018] (2) Filtrate through a filter column with a diameter of 500mm, a height of 1.5m, and a spherical hydroxyapatite filter layer with a height of 1.0m; the filtration rate of the filter column is 15m / hour;

[0019] (4) Filtrate through filter sand with a diameter of 315mm, a height of 1.2m, and a sand layer height of 0.6m;

[0020] (5) Backwash the spherical hydroxyapatite filter column and sand filter every 24 hours.

[0021] Through the above treatment, the fluorine content of the effluent is 0.8mg / L, and the turbidity is <1NTU, which meets the requirements of the corresponding indicators in the national drinking water hygiene standard.

Embodiment 2

[0022] Embodiment 2: If the fluorine content of the raw water is 5 mg / L, the treatment process is as follows:

[0023] (1) Add 150ppm aluminum-based hydroxyapatite defluoridation agent to the water inlet;

[0024] (2) Filter through a filter column with a diameter of 500mm, a height of 1.5m, and a spherical hydroxyapatite filter layer with a height of 1.0m, and the filtration rate of the filter column is 8m / hour;

[0025] (3) Filtrate through filter sand with a diameter of 315mm, a height of 1.2m, and a sand layer height of 0.7m;

[0026] (4) Backwash the spherical hydroxyapatite filter column and sand filter every 24 hours.

[0027] Through the above treatment, the fluorine content of the effluent is 0.7mg / L, and the turbidity is <1NTU, which meets the requirements of the corresponding indicators in the national drinking water hygiene standard.

Embodiment 3

[0028] Embodiment 3: If the fluorine content of the raw water is 10mg / L, the treatment process is as follows:

[0029] (5) Add 300ppm aluminum-based hydroxyapatite defluoridation agent to the water inlet;

[0030] (6) Filter through a filter column with a diameter of 500mm, a height of 2m, and a spherical hydroxyapatite filter layer with a height of 1.8m, and the filtration rate of the filter column is 5m / hour;

[0031] (7) Filter through the filter sand with a diameter of 315mm, a height of 1.2m, and a sand layer height of 0.8m;

[0032] (8) Backwash the spherical hydroxyapatite filter column and sand filter every 24 hours.

[0033] Through the above treatment, the fluorine content of the effluent is 0.8mg / L, and the turbidity is <1NTU, which meets the requirements of the corresponding indicators in the national drinking water hygiene standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com