A kind of preparation method of the composite fluoride removal material applied to the electrolytic zinc sulfate solution to remove fluorine

A technology of zinc sulfate solution and sulfuric acid solution, which is applied in the direction of electrolysis process, electrolysis components, chemical instruments and methods, etc., and can solve the problems of precipitation and redissolution, increase of antimony content in solution, increase of fluorine concentration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

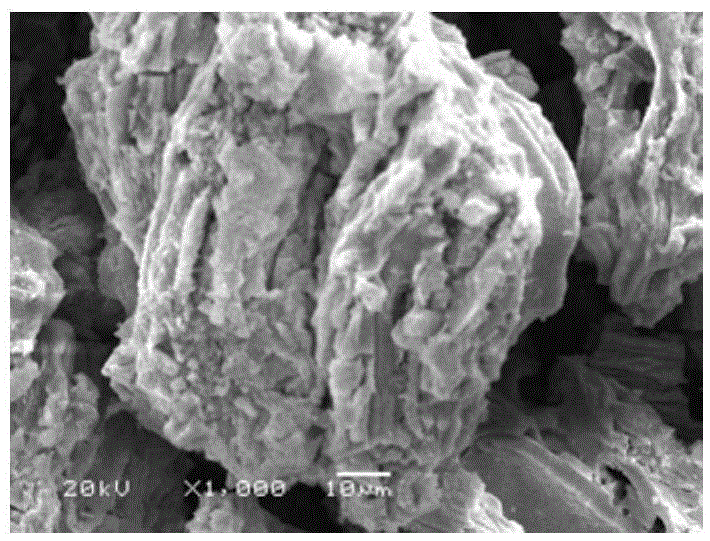

Image

Examples

Embodiment 1

[0027] (1) After the bamboo charcoal is crushed, 2kg of 100-120 mesh bamboo charcoal is sieved, heated to 400°C in an air furnace, and kept for 8 hours;

[0028] (2) Take 1L of sulfuric acid to treat the heat-treated bamboo charcoal according to the solid-to-liquid ratio of 2kg / L. The treatment temperature is 80°C, then wash with a large amount of deionized water until the pH is close to 7, and dry at 60°C after filtration for 24 hours;

[0029] (3) Prepare 1 L of aluminum sulfate solution with a concentration of 2 mol / L, add pretreated bamboo charcoal, and soak for 10 h at a temperature of 50°C. Bamboo charcoal was dried in an oven at 120°C for 12 hours after impregnation;

[0030] (4) Further use 1 L concentration of 20% by mass sodium hydroxide solution for impregnation treatment, stir evenly and let it stand for 24 hours, wash with a large amount of deionized water until the liquid is clarified, filter, and dry at 70°C for 24 hours to obtain the aluminum-loaded bamboo char...

Embodiment 2

[0033] (1) After the bamboo charcoal is crushed, take 2kg of 150-200 mesh bamboo charcoal, heat it to 400°C in an air furnace, and keep it warm for 5 hours;

[0034] (2) Take 2L of sulfuric acid to treat the heat-treated bamboo charcoal at a solid-to-liquid ratio of 1kg / L. The treatment temperature is 80°C, then wash with a large amount of deionized water until the pH is close to 7, and dry at 60°C after filtration for 24 hours;

[0035] (3) Prepare 1 L of aluminum sulfate solution with a concentration of 2 mol / L, add pretreated bamboo charcoal, and soak for 10 hours at a temperature of 50 degrees Celsius. Bamboo charcoal was dried in an oven at 120°C for 12 hours after impregnation;

[0036] (4) Further use 1 L concentration of 20% by mass sodium hydroxide solution for impregnation treatment, stir evenly and let it stand for 24 hours, wash with a large amount of deionized water until the liquid is clarified, filter, and dry at 70°C for 24 hours to obtain the aluminum-loaded b...

Embodiment 3

[0039] (1) After the bamboo charcoal is broken, sieve 2kg of 100-120 mesh bamboo charcoal, heat it to 400°C in an air furnace, and keep it warm for 3 hours;

[0040] (2) Take 1L of sulfuric acid to treat the heat-treated bamboo charcoal according to the solid-to-liquid ratio of 2kg / L. The treatment temperature is 80°C, then wash with a large amount of deionized water until the pH is close to 7, and dry at 60°C after filtration for 24 hours;

[0041] (3) Prepare 1 L of aluminum sulfate solution with a concentration of 2 mol / L, add pretreated bamboo charcoal, and soak for 8 hours at a temperature of 45 degrees Celsius. Bamboo charcoal was dried in an oven at 120°C for 12 hours after impregnation;

[0042] (4) Further use 1 L concentration of 20% by mass sodium hydroxide solution for impregnation treatment, stir evenly and let stand for 24 hours, wash with a large amount of deionized water until the liquid is clarified, filter, and dry at 70° C. for 24 hours to obtain bamboo char...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com