Preparation and regeneration method of water treatment defluoridation material

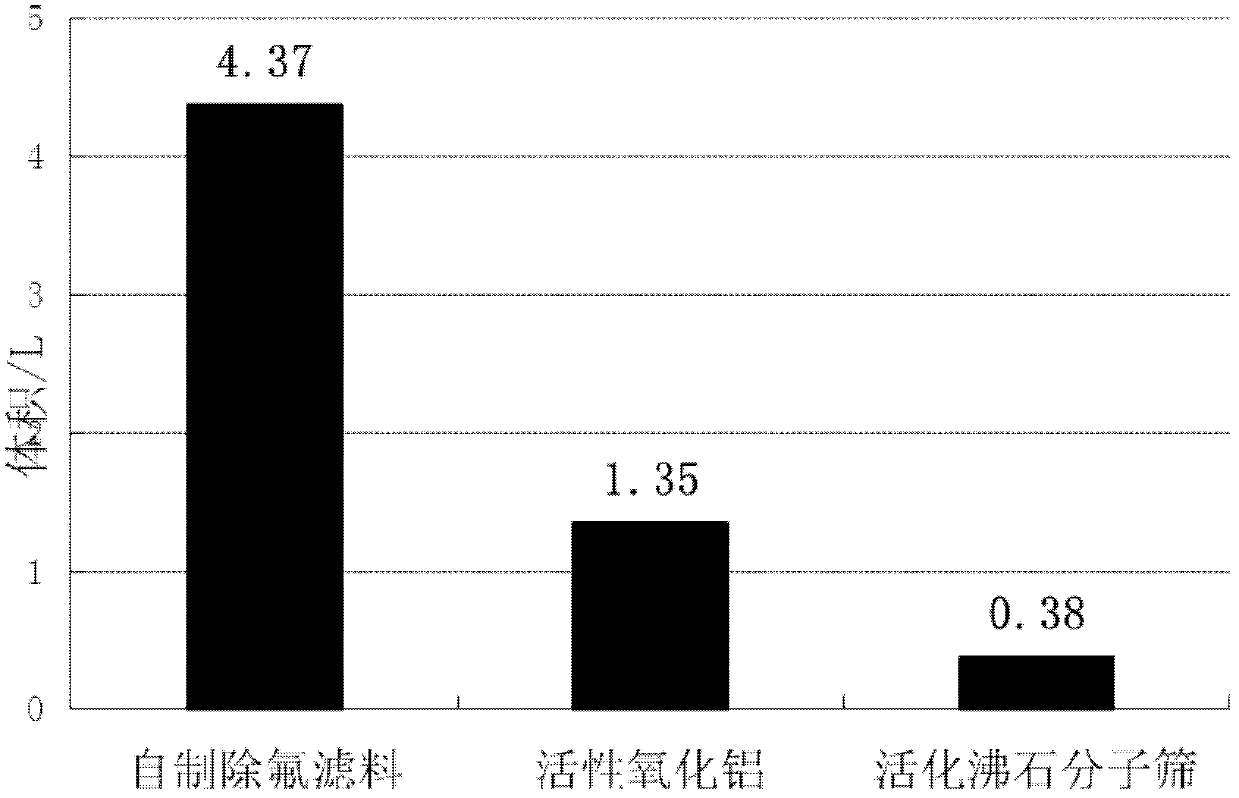

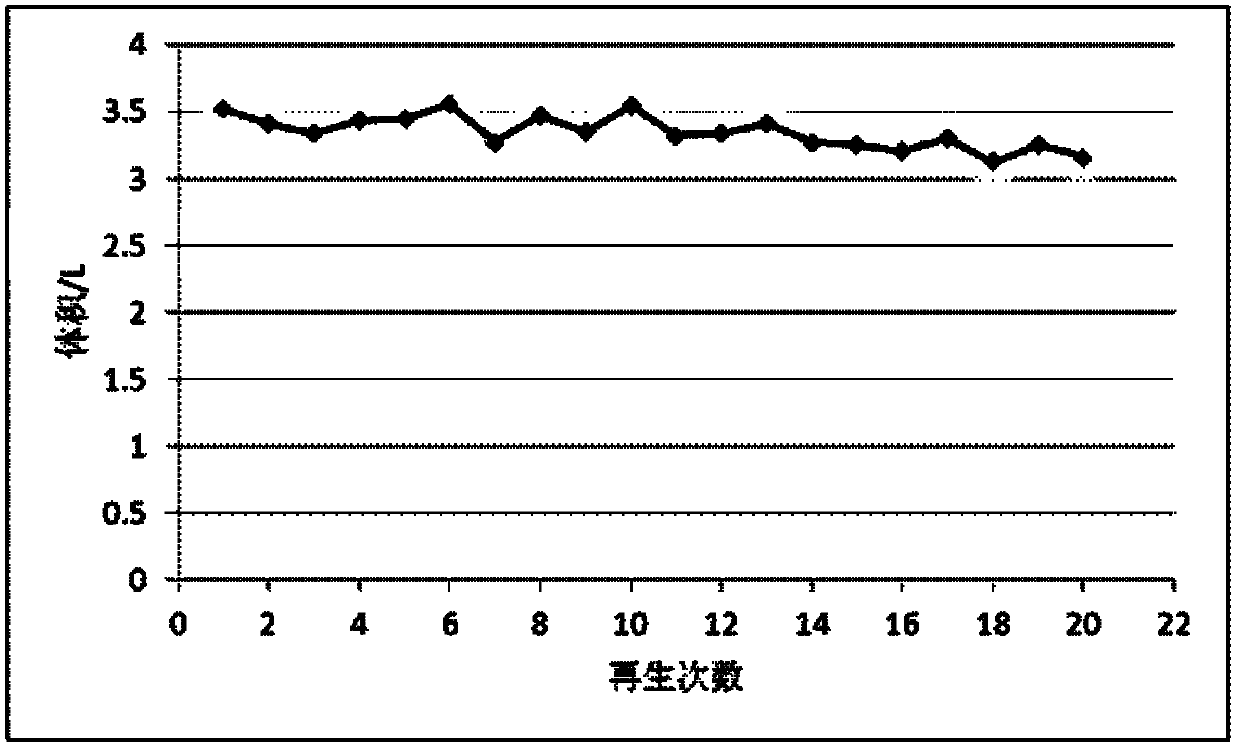

A filter material and raw material technology, which is applied in the regeneration of water treatment defluorination filter material and the preparation of water treatment defluorination filter material, and achieves the effect of good defluorination effect, good application prospect and good reproducibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of preparation method of the defluoridation filter material based on natural mineral, its steps are:

[0033] 1. Raw material selection, using natural calcium and magnesium minerals dolomite;

[0034] 2. Crushing, crushing the raw materials in step 1 and then sieving to obtain particles with a size of about 0.5 or 0.7 or 0.9 or 1.3 or 1.5 or 1.8 or 2.0mm without calcining;

[0035] 3. acid reaction, the granules obtained are placed in the reaction tank, and the phosphoric acid (H 3 PO 4 ) Soak raw materials, raw materials: phosphoric acid (H3 PO 4 ) with a mass volume ratio of 1:0.5, let stand for 2h or 4h or 6h, and remove the acid solution after the treatment;

[0036] 4. Alkali reaction, after the step 3 acid reaction, the particles are then soaked in 4% w / v sodium hydroxide (NaOH) solution for 4h or 6h or 8h, raw material: the quality of sodium hydroxide (NaOH) or potassium hydroxide (KOH) The volume ratio is 1:0.3. After the treatment, the alkali solutio...

Embodiment 2

[0042] A kind of preparation method of the defluoridation filter material based on natural mineral, its steps are:

[0043] 1. Raw material selection, using natural calcium and magnesium mineral calcite;

[0044] 2. Crushing, crushing the raw materials in step 1 and sieving to obtain particles with a size of about 0.8mm or 1.0mm or 1.2mm or 1.4mm;

[0045] 3. Calcination, put the material obtained in step 2 into a furnace (electric furnace or muffle furnace) for calcination, ensure that the raw materials in the furnace are evenly heated at 250°C or 270°C, and under the closed condition of normal pressure 0.1MPa, keep warm for 60 or 80 or Take out the material after 90 or 120 minutes, and wait for it to cool naturally to 5°C or 15°C or 20°C or 24°C or 28°C;

[0046] 4. acid reaction, the particle obtained is placed in the reaction tank, injects the phosphoric acid (H 3 PO 4 ) Soak raw materials, raw materials: phosphoric acid (H 3 PO 4 ) with a mass volume ratio of 1:0.8, ...

Embodiment 3

[0053] A kind of preparation method of the defluoridation filter material based on natural mineral, its steps are:

[0054] 1. Raw material selection, using natural calcium and magnesium minerals dolomite;

[0055] 2. Crushing, crushing the raw materials in step 1 and sieving to obtain particles with a size of about 1.5mm or 1.8mm or 2.0mm;

[0056] 3. Calcination, put the material obtained in step 2 into a furnace (electric furnace or muffle furnace) for calcination to ensure that the raw materials in the furnace are heated evenly at 300°C or 310°C or 330°C or 350°C or 400°C or 420°C, at normal pressure Under the closed condition of 0.1MPa, take out the material after holding the heat for 80 or 100 minutes, and wait for it to cool naturally to 25°C or 29°C or 32°C;

[0057] 4. acid reaction, the particle obtained is placed in the reaction tank, injects the phosphoric acid (H 3 PO 4 ) Soak raw materials, raw materials: phosphoric acid (H 3 PO 4 ) with a mass volume ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com