Liquid phase chemical deposition modified natural zeolite and method for removing fluorine from water

A natural zeolite, chemical deposition technology, applied in chemical instruments and methods, inorganic chemistry, molecular sieves and alkali exchange compounds, etc., can solve the problem that ion exchange reagents cannot fully remove impurities in pores, increase zeolite porosity and specific surface area, zeolite Adsorption performance can not be fully exerted, etc., to achieve the effect of good defluorination effect, high porosity, and high defluorination capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Weigh 2.92g NaCl into a beaker, add deionized water and stir until dissolved, then transfer to a 250ml volumetric flask to constant volume to obtain a 0.2mol / L NaCl solution. The solution was transferred to a reagent bottle, and hydrochloric acid was added dropwise to adjust the pH of the solution to 2.

[0023] (2) Weigh ZrOCl 2 ·8H 2 O 16.11g, placed in a beaker, added deionized water and stirred until completely dissolved, transferred to a 250ml volumetric flask to constant volume, to obtain 0.2mol / L of ZrOCl 2 solution, into a reagent bottle.

[0024] (3) Weigh 50 g of natural zeolite, rinse it with tap water for 3 times, and place it in an oven to fully dry it.

[0025] (4) Put the zeolite obtained in (3) into a beaker, add 150ml of 0.2mol / L NaCl solution to make the solid-liquid ratio 1:3, and soak for 12h. Stir from time to time during the soaking process to make the solid-liquid contact fully and the adsorption fully proceed.

[0026] (5) The zeolite ob...

Embodiment 2

[0036] The preparation process steps are the same as in Example 1, except that in (1), 7.31 g of NaCl is weighed to prepare a solution with a concentration of 0.5 mol / L, and the pH is adjusted to 2.5. In the (2), weigh ZrOCl 2 ·8H 2 O 40.3g, prepared into a solution with a concentration of 0.5mol / L. In (3), rinse 4 times with tap water. In (4), 100 ml of 0.5 mol / L NaCl solution was added to make the solid-liquid ratio 1:2, and soaked for 18 hours. Add 0.5mol / L ZrOCl in the (6) 2 Solution 100mL, solid-liquid ratio 1:2, soak for 18h. 1N ammonia water was added to (7), and the pH of the solid-liquid mixture was adjusted to 8.

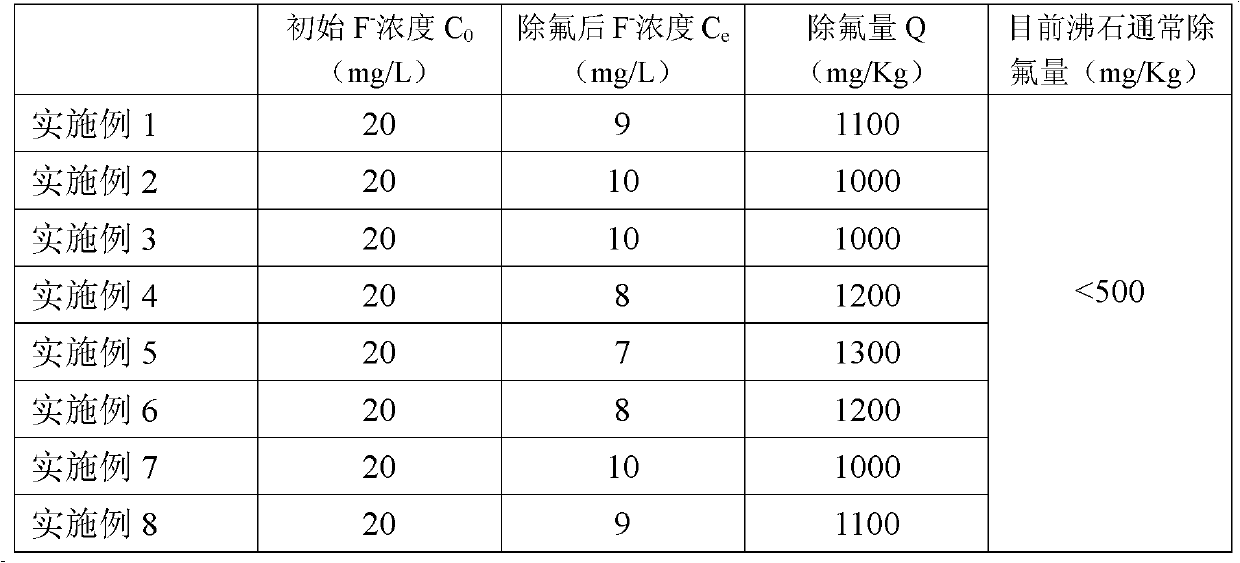

[0037] Fluoride removal capacity see table 1

Embodiment 3

[0039] The preparation process steps are the same as in Example 1, except that in (1), 14.62 g of NaCl is weighed to prepare a solution with a concentration of 1.0 mol / L, and the pH=3 is adjusted. In the (2), weigh ZrOCl 2 ·8H 2 O 80.6g, prepared into a solution with a concentration of 1.0mol / L. In (4), 67 ml of 1.0 mol / L NaCl solution was added to make the solid-liquid ratio 3:4, and soaked for 24 hours. Add 1.0mol / L ZrOCl in the (6) 2 Solution 67mL, solid-liquid ratio 3:4, soak for 24h. 1N ammonia water was added to (7), and the pH of the solid-liquid mixture was adjusted to 9.

[0040] Fluoride removal capacity see table 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com