A lime digestion steam treatment device

A technology of processing device and steam, applied in chemical instruments and methods, separation of dispersed particles, use of liquid separating agent, etc., can solve the problems of jumping into lime discharge device, polluting the surrounding environment, caking and blocking of discharge device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

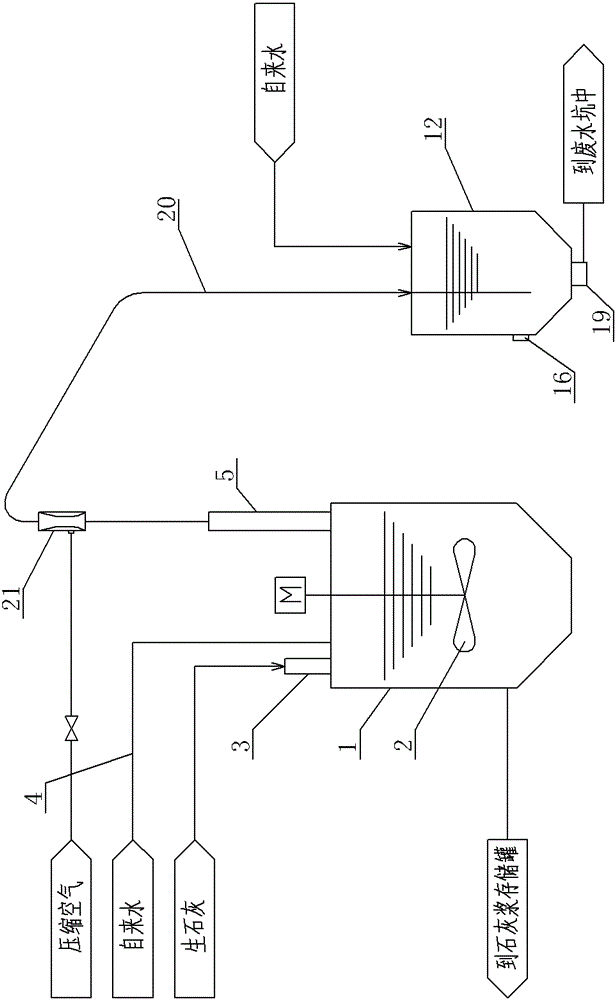

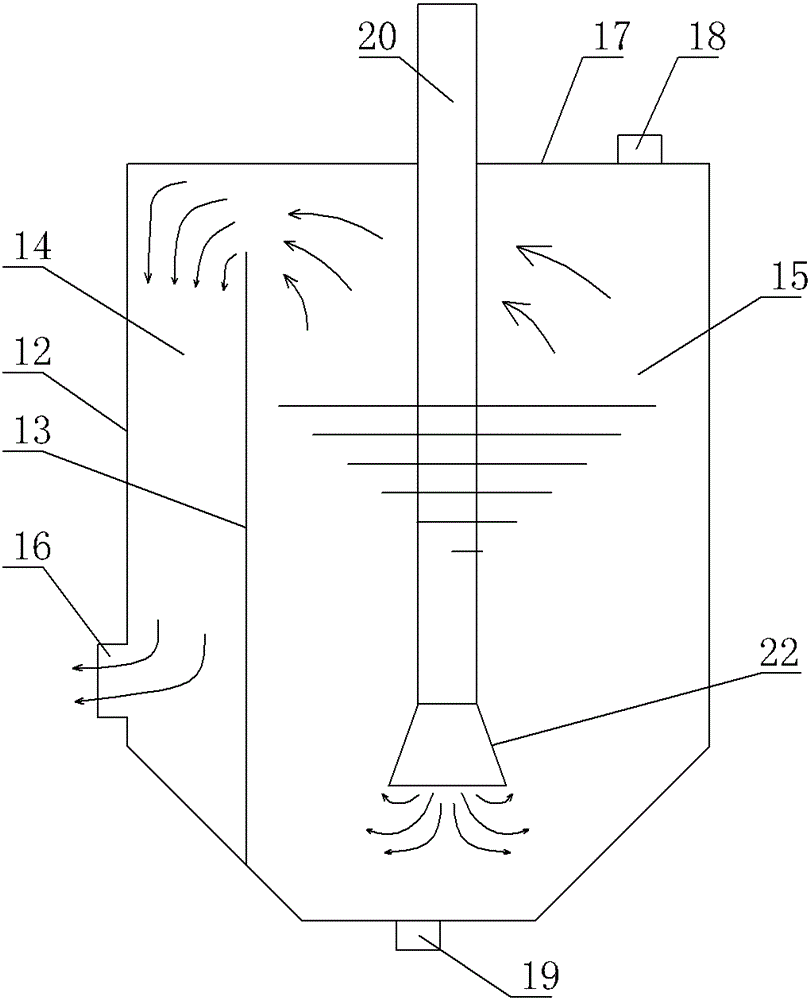

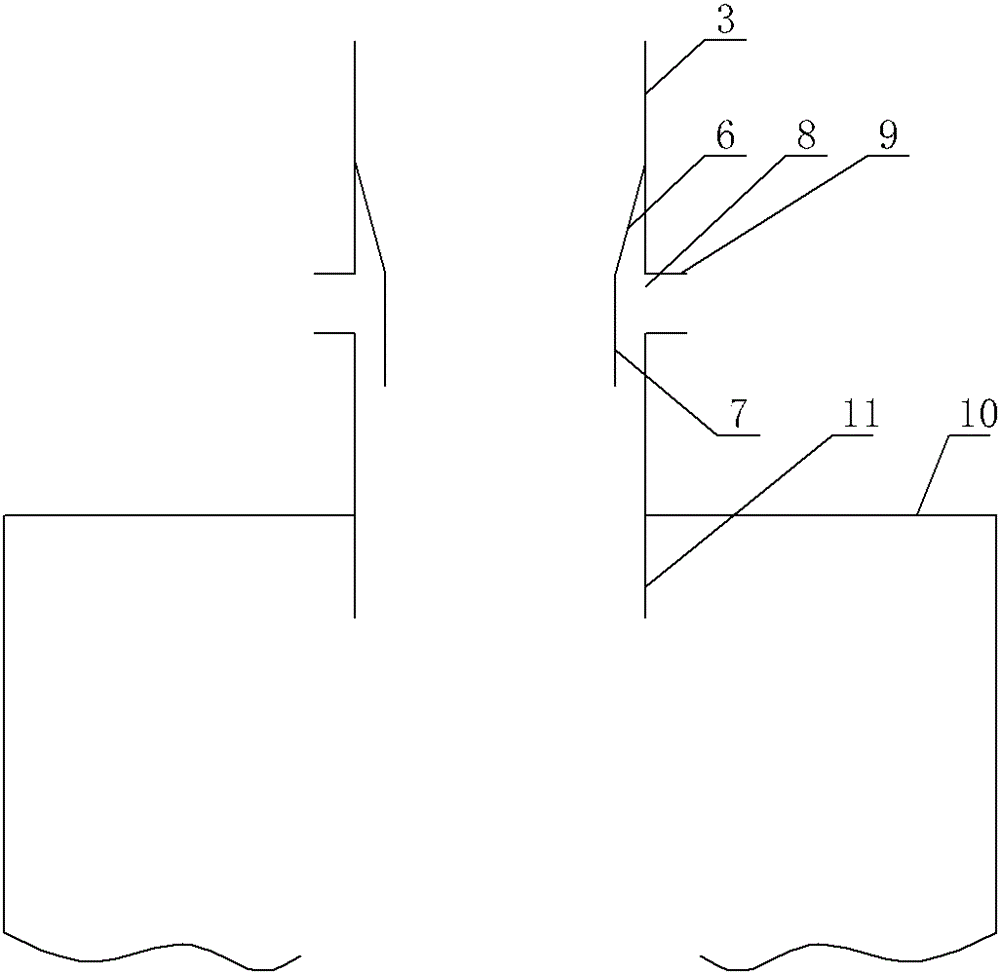

[0016] A lime digestion steam treatment device, see Figure 1 ~ Figure 3 : It comprises a quicklime digestion tank 1, a stirrer 2 is arranged in the quicklime digestion tank 1, a feed pipe 3, a water inlet pipe 4, and a steam exhaust pipe 5 are respectively arranged on the quicklime digestion tank 1, and the bottom of the quicklime digestion tank 1 is provided with The outlet is connected to the lime slurry storage tank. The middle part of the inner cavity of the feed pipe 3 is provided with ash guide pipe structure 6 closed from top to bottom. The lower part of the ash guide pipe structure 6 can also be a cylindrical guide structure 7. The outer wall of the corresponding feed pipe 3 is provided with an air supply hole 8, and the external air supply pipe 9 is connected to the air supply hole 8, and the gas in the air supply hole 8 that passes into the feed pipe 4 goes downward along the outer wall of the guide pipe structure 6 flow, the bottom of the feed pipe 3 extends downwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com