Environmental protection and high temperature resistant PVC (polyvinyl chloride) compound calcium-zinc stabilizer

A calcium-zinc composite and high-temperature-resistant technology, applied in the field of PVC stabilizers, can solve problems such as threats to health and environmental pollution, and achieve the effects of ensuring stability, excellent color, and excellent appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Weigh 15kg of zinc stearate, 20kg of calcium stearate, 20kg of stearyl benzoylmethane, 30kg of zeolite, 10kg of sek, and 5kg of sodium perchlorate, put them into the mixer, and knead evenly to obtain an environment-friendly high temperature resistant PVC calcium zinc composite stabilizer.

Embodiment 2

[0020] Weigh 15kg of zinc stearate, 20kg of calcium stearate, 20kg of dibenzoylmethane, 30kg of zeolite, 10kg of sek, and 5kg of sodium perchlorate, put them into the mixer, and knead them evenly to obtain environmentally friendly high-temperature resistant PVC calcium Zinc complex stabilizer.

[0021] When the environment-friendly high-temperature-resistant PVC calcium-zinc composite stabilizer of the above-mentioned embodiment 1 and embodiment 2 is actually applied to PVC products, its formula can refer to Table 1:

[0022] Table 1

[0023]

Dosage (parts by mass)

Polyvinyl chloride (PVC SG3)

100

Ground calcium carbonate (2500)

50

Epoxidized soybean oil (ESBO)

4

Trioctyl trimellitate (TOTM)

45

PVC calcium zinc composite stabilizer

5

3

PE wax

0.3

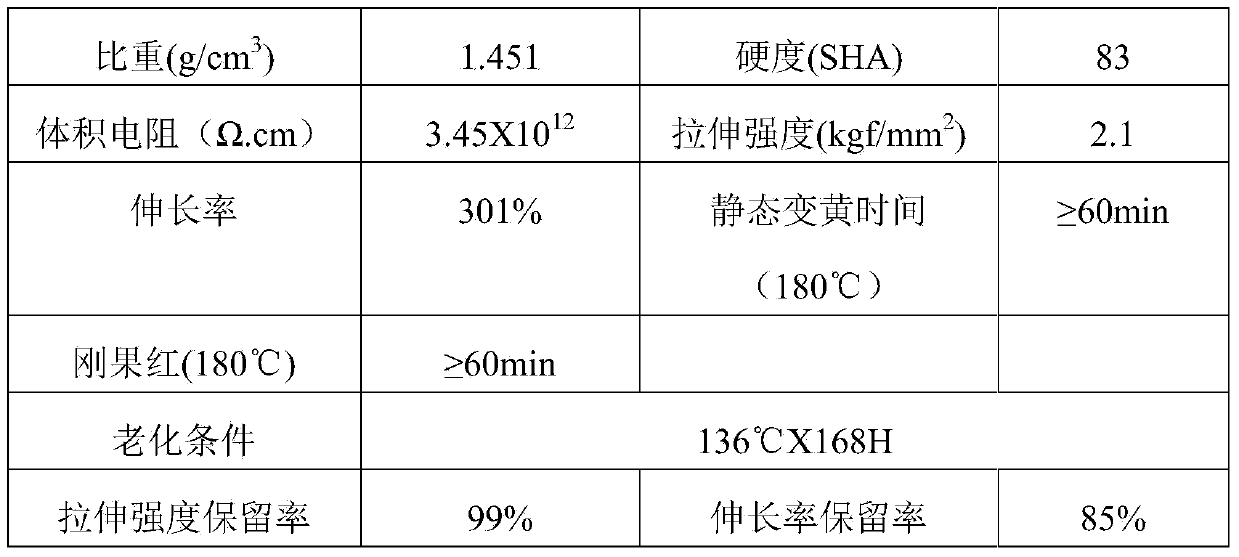

[0024] The test results of PVC products adopting the above formula are shown in Table 2:

[0025]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com