Wearproof rubber material

A technology of wear-resistant rubber and butadiene rubber, which is applied in the field of wear-resistant rubber materials, can solve the problems of insufficient performance of the diaphragm and achieve the effect of high insulation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

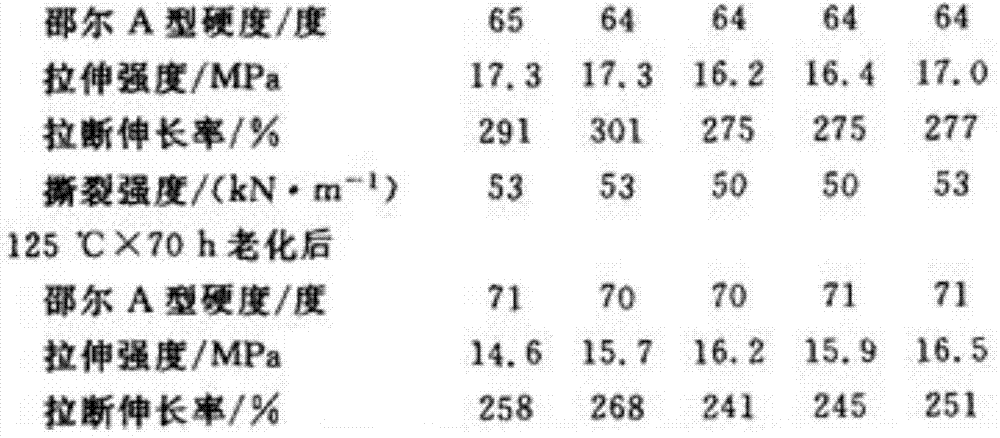

Examples

Embodiment 1

[0014] A wear-resistant rubber material, component A

[0015] The layer is composed of styrene-butadiene rubber, polybutadiene rubber, nano-carbon fiber and silicone composition, and the B-component layer is composed of neoprene, isoprene rubber organic, polybutadiene rubber, brominated butyl rubber and ternary Ethylene-propylene rubber is combined, and the organic combination method is a high-temperature polymerization method, wherein the molar ratio of the styrene-butadiene rubber, butadiene rubber and organosilicon compound is 2:1.5:3; the neoprene rubber, isoprene rubber The molar ratio of organic, polybutadiene rubber, bromobutyl rubber, EPDM rubber and natural rubber is 3:2.5:3.5:2.5. The silicone composition described therein is polypropylene adiene siloxane, polybutadiene siloxane, polyphenylmethyl siloxane.

[0016] In the preparation method of the above-mentioned wear-resistant rubber material, the styrene-butadiene rubber, butadiene rubber and organosilicon compoun...

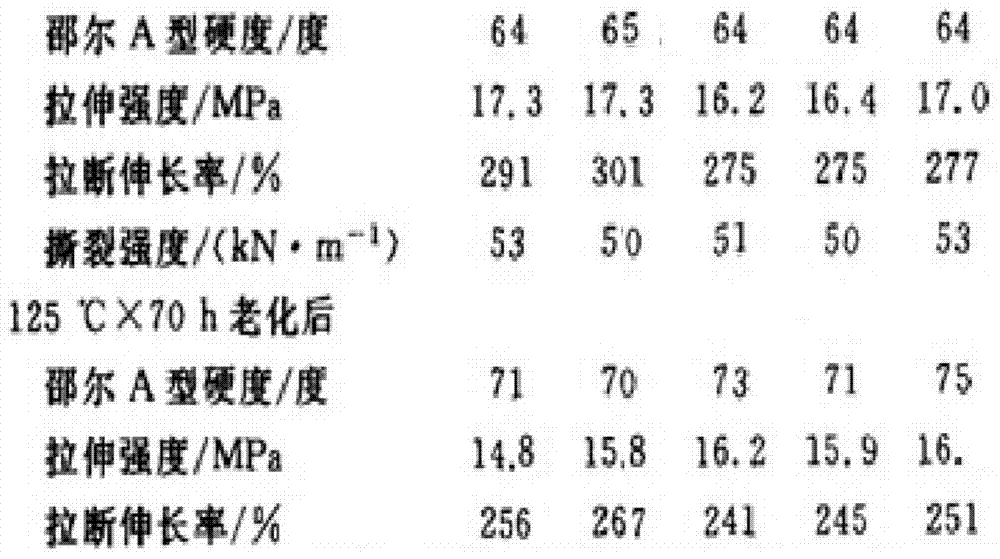

Embodiment 2

[0020] A wear-resistant rubber material, the A-component layer is organically combined with styrene-butadiene rubber, butadiene rubber, nano-carbon fiber and silicone composition, and the B-component layer is composed of neoprene rubber, isoprene rubber organic, polybutadiene Rubber, brominated butyl rubber and EPDM rubber are combined, and the organic combination method is a high-temperature polymerization method, wherein the molar ratio of the styrene-butadiene rubber, butadiene rubber and organosilicon compound is 2:1.5:3 The chloroprene rubber, isoprene rubber organic, polybutadiene rubber, brominated butyl rubber, EPDM rubber and natural rubber have a molar ratio of 3:2.5:3.5:2.5, wherein the organic silicon combination It is composed of polyvinyl siloxane, polypropylene adiene siloxane, polybutadiene siloxane, polyphenylmethyl siloxane and polyphenylene 2,4 dimethyl siloxane. The natural rubber is smoked rubber sheet, white crepe rubber sheet, granule rubber, rubber crep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com