Pulse X-ray diode for measuring spatial distribution characteristics of material

A space distribution, diode technology, applied in X-ray tubes, X-ray tube electrodes, X-ray tube components, etc., to achieve the effects of increasing the output ratio, improving environmental adaptability, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

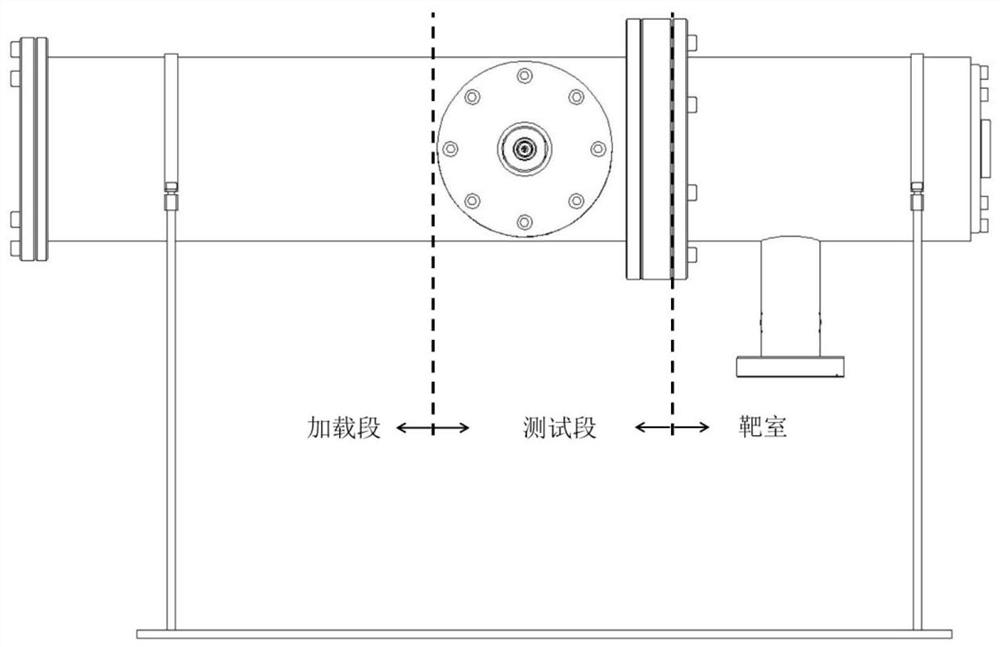

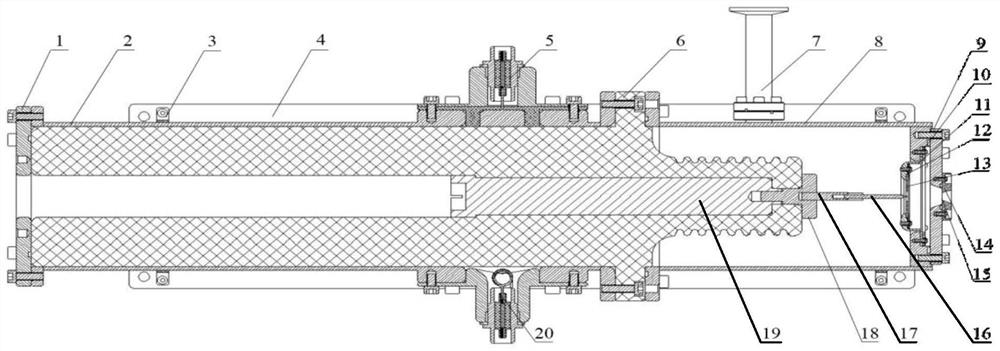

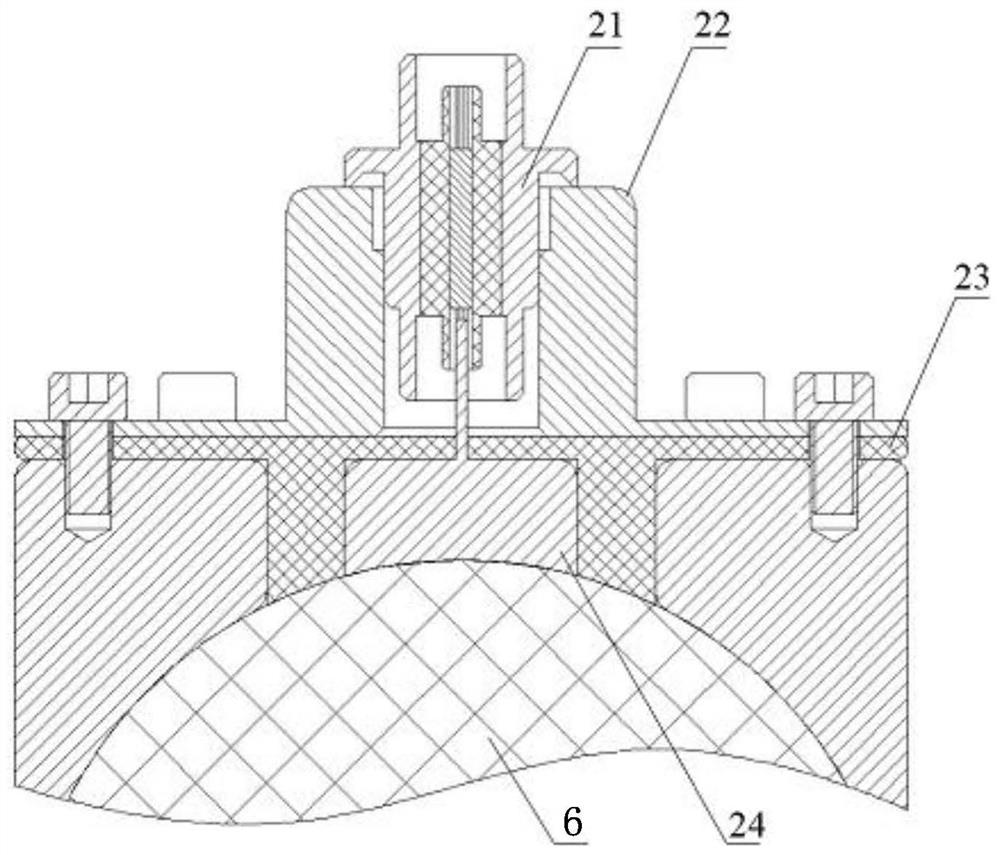

[0043] Such as Figure 1-Figure 5 As shown, a pulsed X-ray diode used for measuring the spatial distribution characteristics of materials includes an air-filled sealing flange 1, a diode tube 2, an insulating tube 6, a diode case 8, an anode assembly, a cathode assembly and a vacuum cover 9;

[0044] The insulating cylinder 6 is a convex structure whose outer wall is large at one end and small at the other end, the diode tube 2 is arranged outside the large end of the convex structure, and the diode case 8 is arranged outside the small end of the convex structure;

[0045] The cathode assembly is installed on the end of the diode casing 8 away from the large end of the convex structure through the cathode disc crimping flange 10, and the vacuum cover plate 9 is arranged on the end of the diode casing 8 away from the large end of the convex structure. A vacuum target chamber is formed between the diode case 8, the vacuum cover plate 9 and the insulating cylinder 6, and the vacuum...

Embodiment 2

[0071] This embodiment is based on Embodiment 1. The outer walls of the diode tube 2 and the diode case 8 are provided with fixing hoops 3 , and the pulsed X-ray diode is detachably connected to the fixing base 4 through the fixing hoops 3 during use.

[0072] Specifically, the cylinder of the pulsed X-ray diode is placed on the two semicircular supports attached to the fixed base 4, and the fixed hoop 3 and the fixed base 4 are locked with screws.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com