Fluorine-free refrigerant and its preparation method

A refrigerant, fluorine-free technology, applied in chemical instruments and methods, materials for heat exchange, etc., can solve the problems of waste of resources, elimination of development trends, high cost, and improve safety, reduce production costs, and reduce flammability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

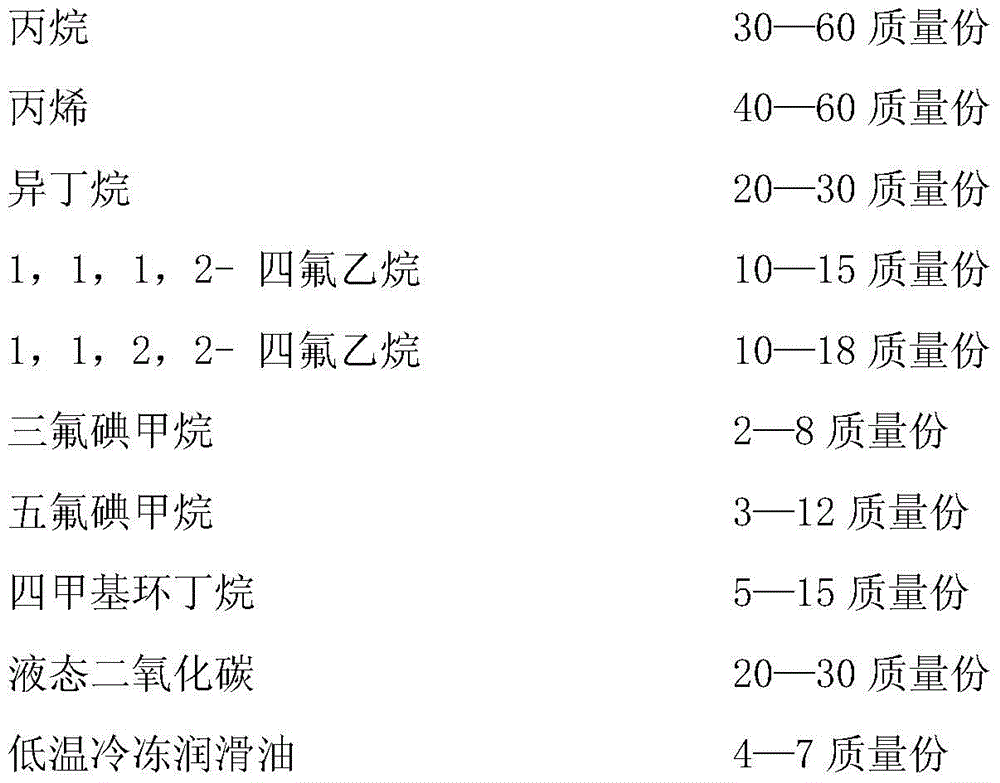

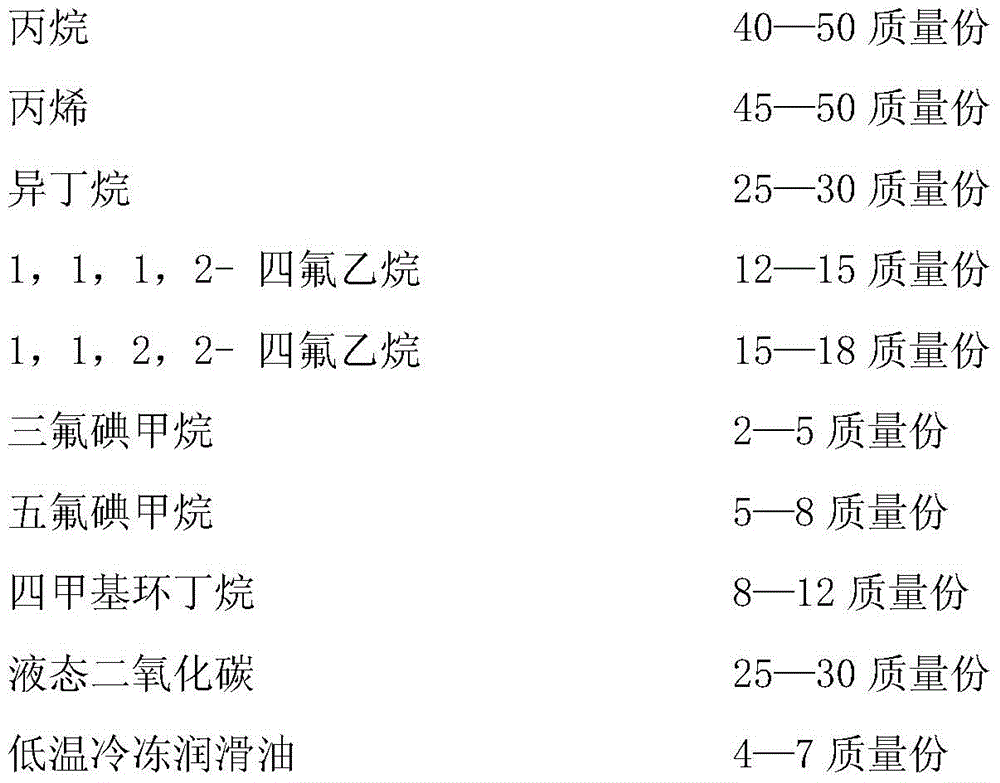

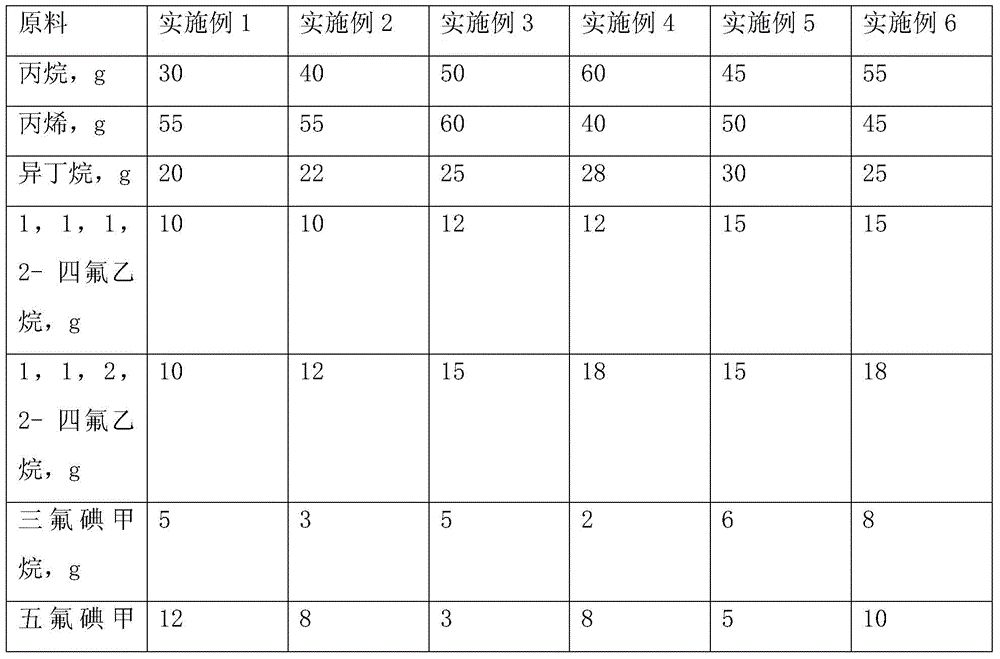

[0015] The technical solutions of the present invention will be further described below through specific examples. The selection of cryogenic refrigeration lubricants is based on the pour point. According to liquid carbon dioxide, cryogenic refrigeration oil, propane, propylene, isobutane, 1,1,1,2-tetrafluoroethane, 1,1,2,2-tetrafluoroethane, trifluoroiodomethane, pentafluoro The order of methyl iodide and tetramethylcyclobutane is prepared by mixing the raw materials shown in the following table in sequence.

[0016]

[0017]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com