Method for preparing coke

A technology of coke and carbonization, which is applied in the formulation field of shaped coke in inclined bottom coke ovens. It can solve the problems of poor thermal stability and poor hot and cold strength of marking lines, and achieve the effects of low porosity, increased strength and reduced loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] 1) Crushing of raw materials

[0078] Main coking coal, lean coal, anthracite, coke powder, pitch and petroleum coke are separately pulverized to produce main coke coal powder, lean coal powder, anthracite powder, fine coke powder, pitch powder and petroleum coke powder. The particle size of pulverized coal is 40 mesh, the particle size of lean coal is 40 mesh, the particle size of anthracite powder is 60 mesh, the particle size of fine coke powder is 100 mesh, the particle size of asphalt powder is 30 mesh, and the particle size of petroleum coke is 60 mesh. The final raw material powders are stored in the corresponding raw material bins respectively for standby.

[0079] 2) Weighing and mixing of raw materials

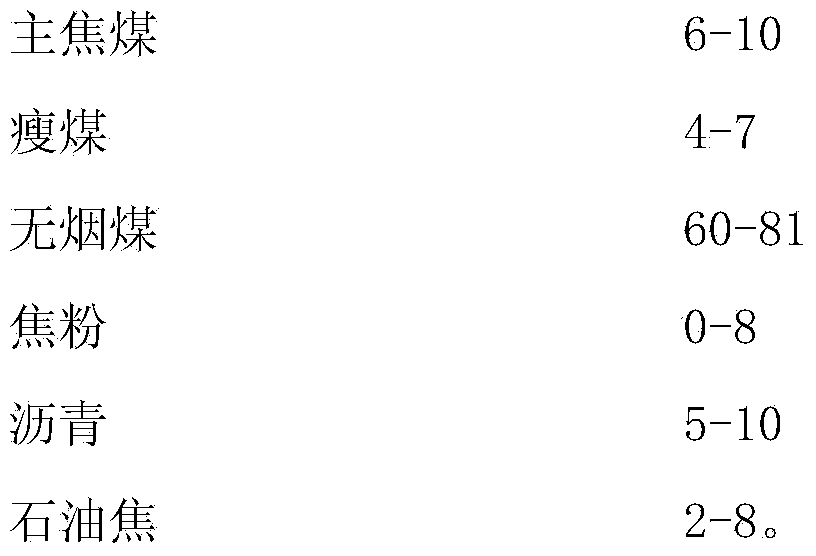

[0080] 2A) Weigh the raw materials according to the following weight ratio (×10kg)

[0081]

[0082] 2B) Put main coke coal powder, lean coal powder, anthracite coal powder, fine coke powder, asphalt powder and petroleum coke powder in a double-screw mixe...

Embodiment 2

[0105] 1) Crushing of raw materials

[0106] Separately pulverize main coking coal, lean coal, anthracite, pitch and petroleum coke to produce main coking coal powder, lean coal powder, anthracite powder, pitch powder and petroleum coke powder, wherein the particle size of main coking coal powder after crushing is 30 mesh , The particle size of lean coal powder is 50 mesh, the particle size of anthracite powder is 50 mesh, the particle size of asphalt powder is 20 mesh, and the particle size of petroleum coke powder is 150 mesh. The crushed raw material powder is stored in the corresponding raw material warehouse for standby.

[0107] 2) Weighing and mixing of raw materials

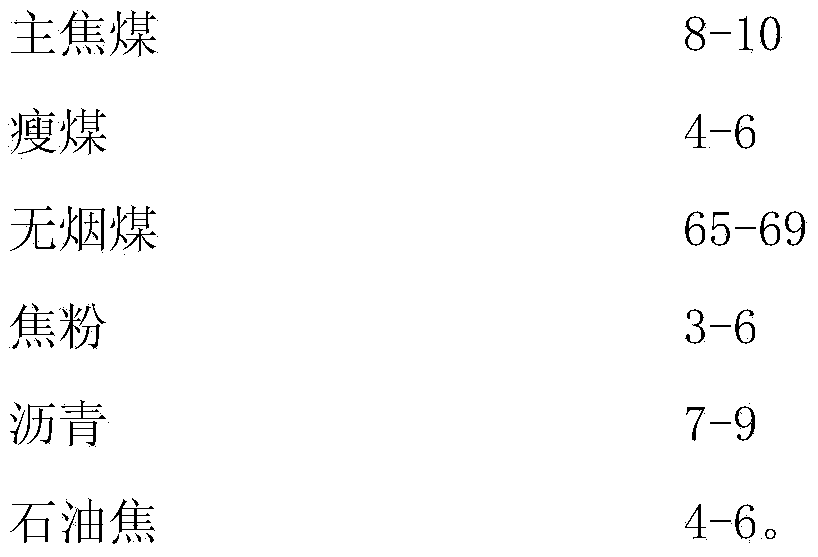

[0108] 2A) Weigh the raw materials according to the following weight ratio (×10kg)

[0109]

[0110] 2B) Put coking coal powder, lean coal, anthracite coal powder, asphalt powder and petroleum coke powder in a twin-screw mixer and mix them evenly to prepare mixed raw material powder, wherein the stirr...

Embodiment 3

[0125] 1) Crushing of raw materials

[0126] Main coking coal, lean coal, anthracite, coke powder, pitch and petroleum coke are separately pulverized to produce main coke coal powder, lean coal powder, anthracite powder, fine coke powder, pitch powder and petroleum coke powder. The particle size of pulverized coal is 50 mesh, the particle size of lean coal is 30 mesh, the particle size of anthracite powder is 70 mesh, the particle size of fine coke powder is 150 mesh, the particle size of asphalt powder is 40 mesh, and the particle size of petroleum coke is 80 mesh. The final raw material powders are stored in the corresponding raw material bins respectively for standby.

[0127] 2) Weighing and mixing of raw materials

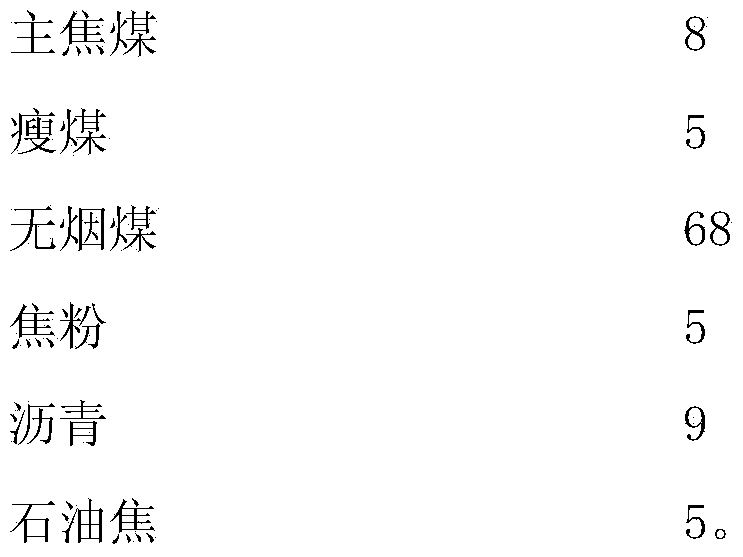

[0128] 2A) Weigh the raw materials according to the following weight ratio (×10kg)

[0129]

[0130] 2B) Put main coke coal powder, lean coal powder, anthracite coal powder, fine coke powder, asphalt powder, and petroleum coke powder in a double-helix mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com