Self-absorption plastic floor and manufacturing method thereof

A technology for plastic flooring and manufacturing methods, which can be applied to building structures, floors, buildings, etc., and can solve the problems of low self-adsorption capacity, unsatisfactory compatibility between metal powder and matrix resin, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

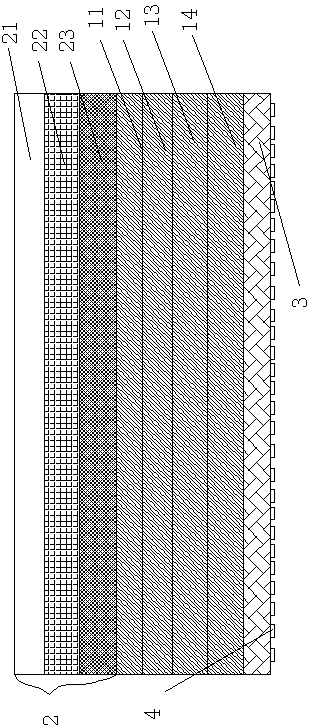

[0039] Example 1. Such as figure 1 As shown, a self-absorbing plastic floor is characterized in that the thickness of the self-adsorbing plastic floor is 3mm, and the weight per square meter is 5.7kg; the self-adsorbing plastic floor includes four base material layers 11, 12, 13, 14. The top surface of the topmost base material layer 11 is provided with a surface layer 2, the bottom surface of the bottommost base material layer 14 is provided with an elastic anti-slip film 3, and the bottom surface of the elastic anti-slip film 3 is provided with a number of grooves. The protrusions 4 have the same height; the base material layer contains fillers, and the fillers are one or more of barite powder, quartz sand or microsilica; the base material layer contains PVC, staple fiber. The short fibers are glass fibers.

[0040] The surface layer is further divided into three layers from top to bottom, the first layer is a UV layer 21, the purpose is to improve the gloss and scratch r...

Embodiment 2

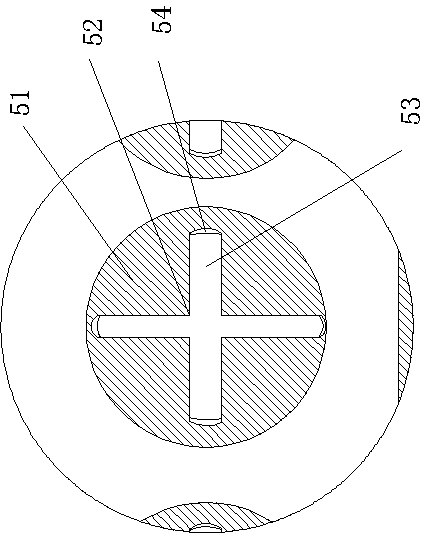

[0053] Example 2. The only difference between this embodiment and embodiment 1 is: as Figure 4 , Figure 5 As shown, the protrusions include a protrusion 45 with a circular cross section and an annular groove 56 inside, and an automobile steering wheel-shaped protrusion 47 is disposed inside the annular groove 56 .

Embodiment 3

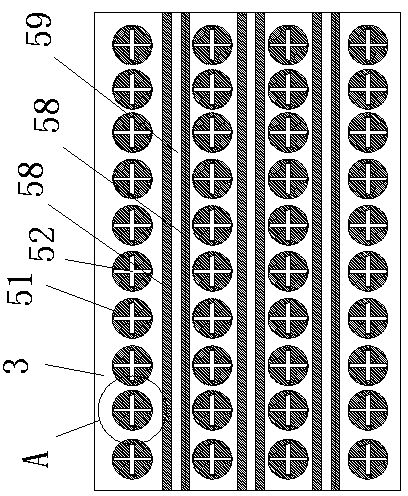

[0054] Example 3. The only difference between this embodiment and embodiment 2 is: as Figure 6 As shown, the protrusions include several strip-shaped convex ribs 58 whose central axis is parallel to the long side of the floor and whose length is equal to the long side or whose central axis is parallel to the short side of the floor and whose length is equal to the short side. Ribbon-shaped groove 59 . The central axis of the strip-shaped convex rib is a wavy curve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com