A solid fuel clean combustion device and combustion method

A combustion device and solid fuel technology, which are applied to the combustion of solid fuel, combustion method, combustion chamber, etc., can solve the problems of inability to achieve balanced combustion of volatile matter and fixed carbon, and inability to achieve clean combustion of solid fuel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

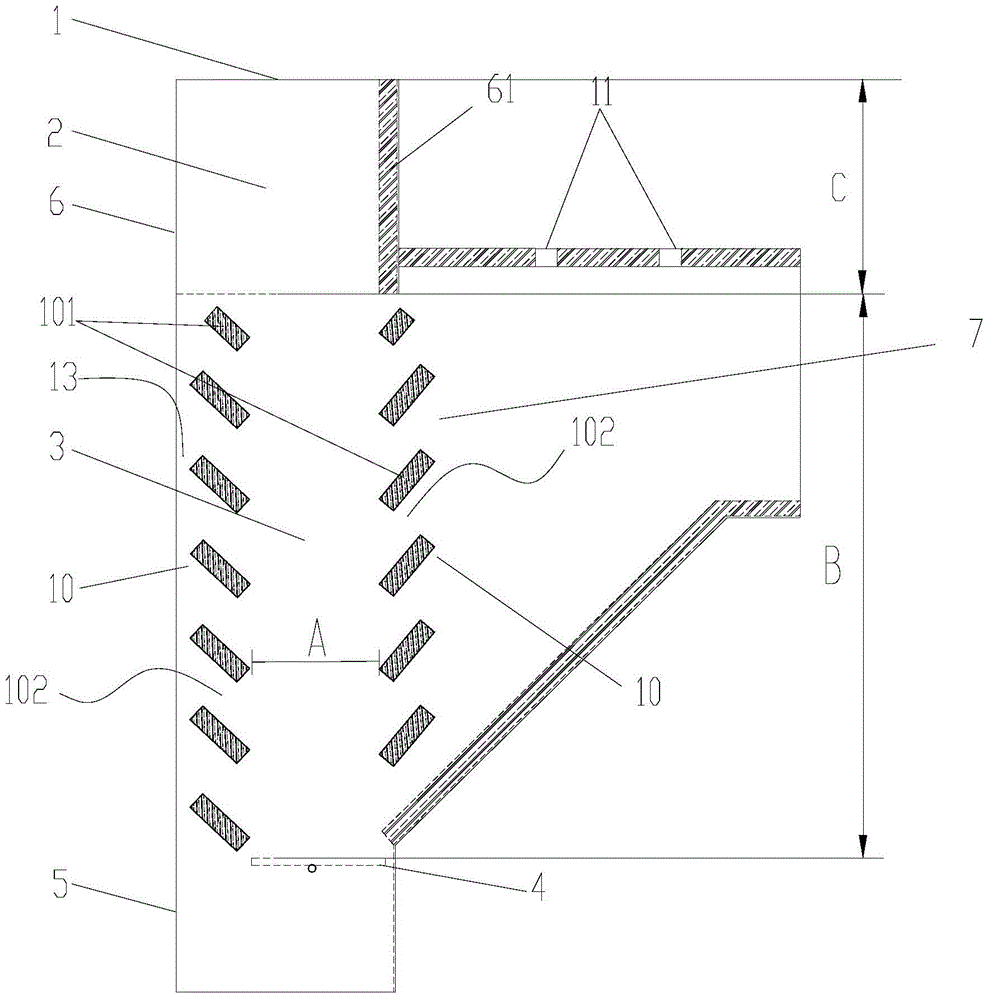

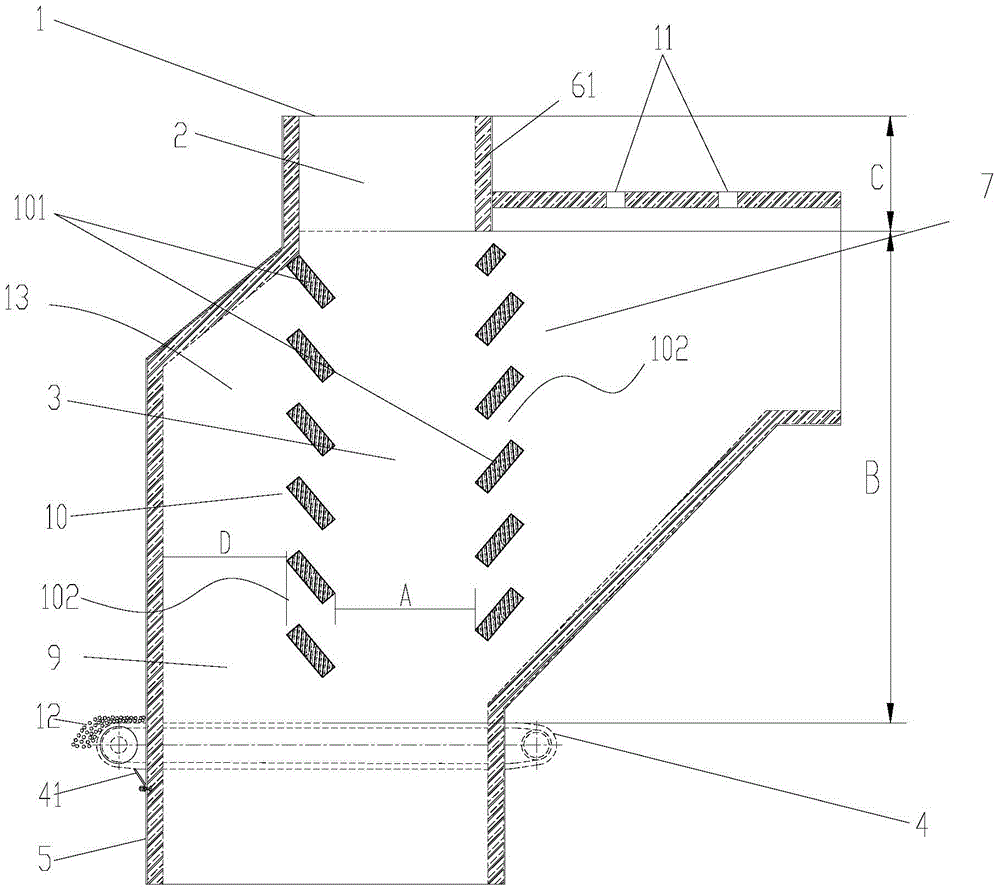

[0055] like figure 1 As shown, the solid fuel clean combustion device of this embodiment includes a furnace body 6, an upper air inlet 1 is arranged on the upper part or the top of the furnace body 6, and a lower air inlet 5 is arranged on the lower part or the bottom. A furnace cavity is arranged inside. In this embodiment, the upper air inlet 1 is arranged at the top of the furnace body 6 , and the lower air inlet 5 is arranged at the lower part of the furnace body 6 . The fire outlet 7 is arranged on one side of the furnace body 6. In this embodiment, the fire outlet 7 is preferably arranged on the right side of the furnace body 6, and the setting position of the fire outlet 7 is lower than the The above air inlet 1 and the height of the fire outlet 7 are within the conventional selection range in this field. In this embodiment, the height of the fire outlet 7 is not less than 200mm. The positional relationship between the lower air inlet 5 and the fire outlet 7 can be se...

Embodiment 2

[0074] This embodiment provides a clean combustion device for solid fuel, which is different from Embodiment 1 in that: in this embodiment, the ventilation fins of the ventilation wall 10 are composed of several vertically connected ventilation fins; or The ventilation wall 10 is composed of several vertically arranged ventilation fins or baffle plates, and several of the ventilation fins or baffle plates are located on the same longitudinal plane, and the distance between the top of each of the ventilation fins or baffle plates is at the distance between its adjacent The bottom end of the upper ventilation sheet or the baffle has a gap suitable for ventilation and capable of blocking the leakage of solid fuel.

Embodiment 3

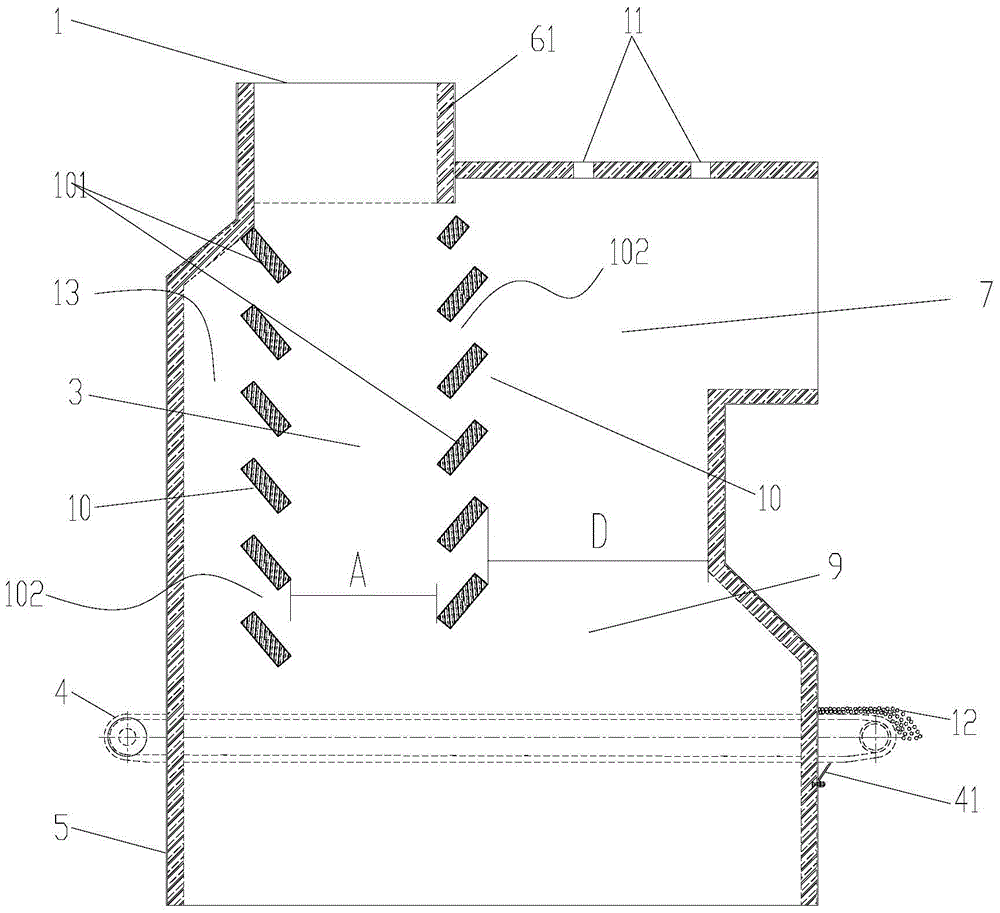

[0076] This embodiment provides a clean combustion device for solid fuel, which is different from Embodiment 1 in that: at least one of the two ventilation walls is inclined, so that the combustion zone 3 is formed to be large at the top and small at the bottom or small at the top Under large burning space.

[0077] Specifically, in the present embodiment, the two ventilation walls 10 are arranged obliquely, and the direction of inclination of the ventilation walls is inclined downward from the outside to the inside, so that the combustion zone 3 is formed to be large at the top and small at the bottom. inverted trapezoid.

[0078] Still further, the inclined ventilating wall 10 is composed of several fixed fire grates 101 arranged at intervals in the longitudinal direction, and the fixed fire grates 101 are arranged inclined and downward toward the interior of the combustion zone 3, so that the solid fuel is discharged from the upper air inlet. 1. When entering the combustio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com