Regenerative gas heating furnace control system

A gas heating and control system technology, applied in furnace control devices, control combustion, lighting and heating equipment, etc., can solve the problems of immature regenerative heating technology, high labor intensity of operators, and poor temperature control accuracy. The effect of easy maintenance, high degree of automation and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

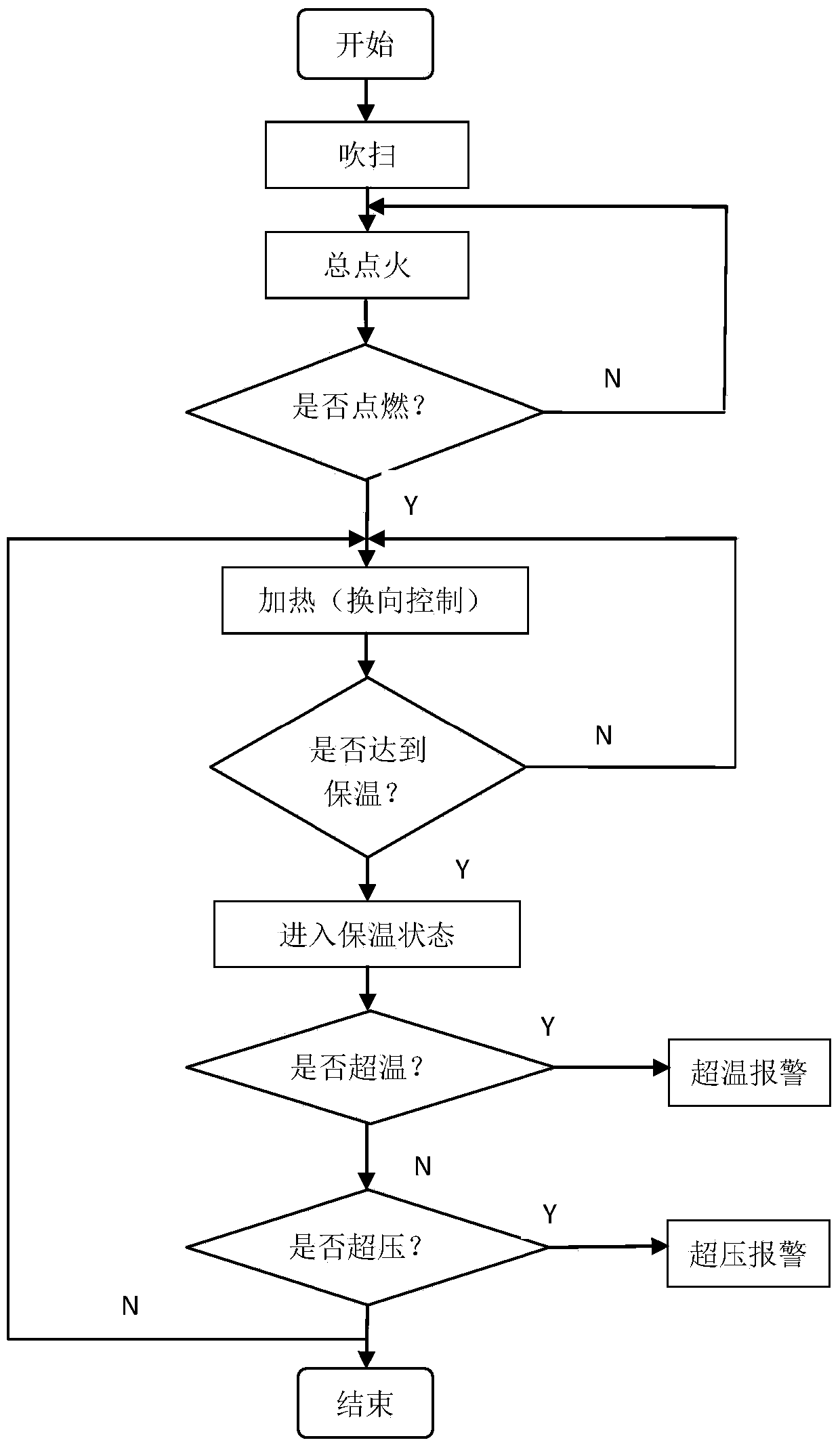

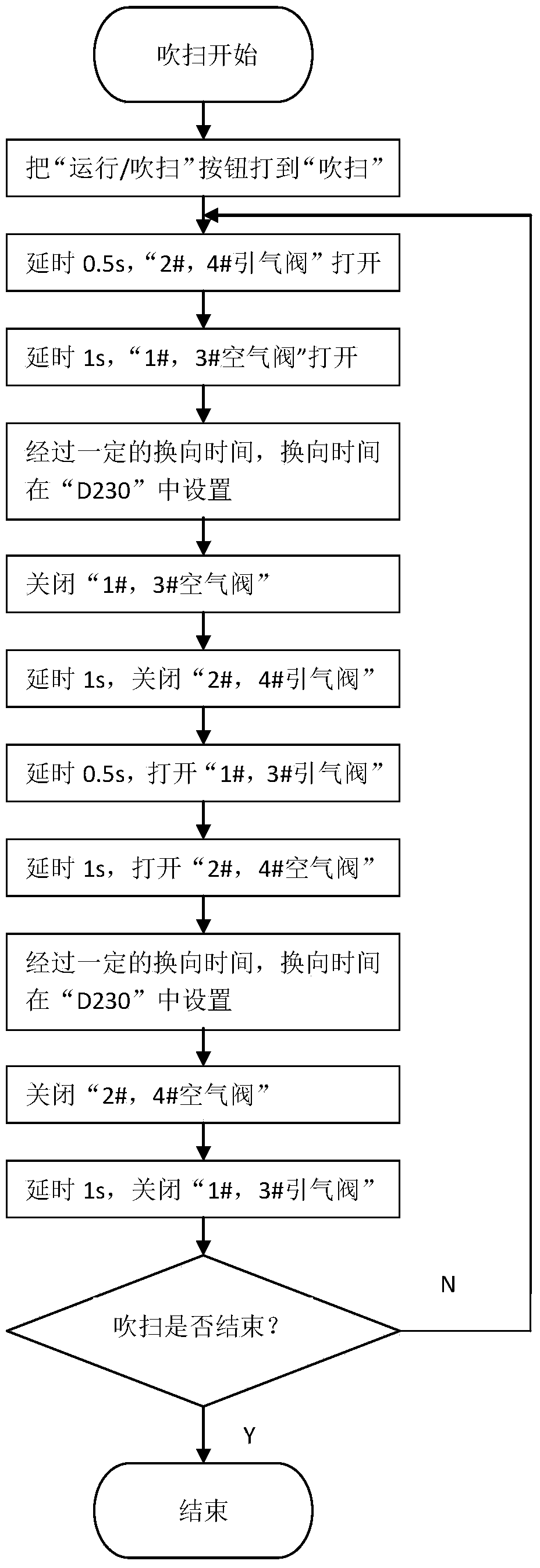

[0039] Below in conjunction with accompanying drawing, the present invention is described in detail:

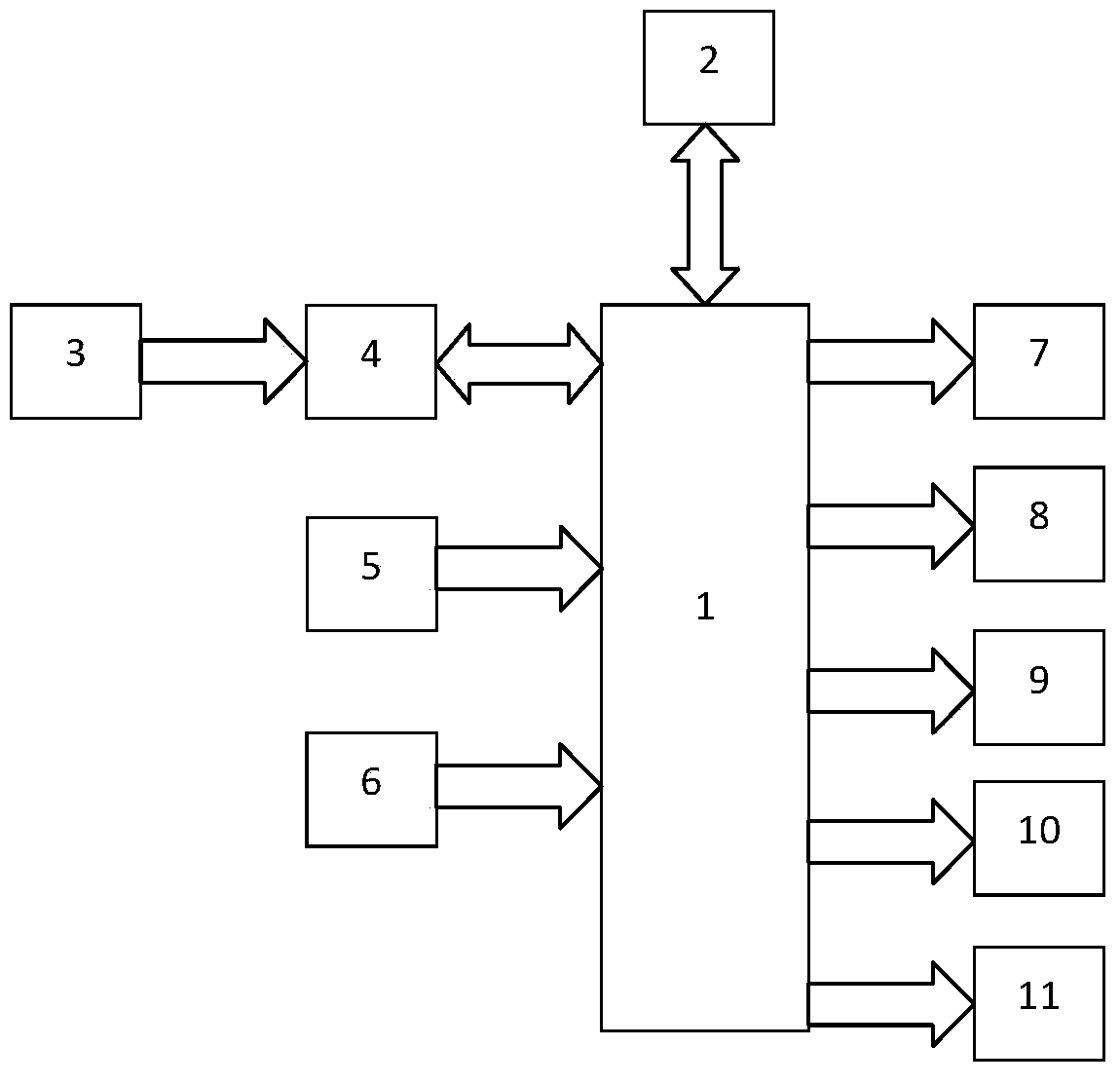

[0040] A regenerative gas heating furnace control system, including a programmable logic controller PLC1, a human-machine interface touch screen 2, two temperature control instruments 4, a temperature sensor 3, a pressure sensor 6, an electromagnetic reversing valve, and an ignition coil 9 , Ion flame detector 5, alarm 10.

[0041] The main control programmable logic controller PLC1 is installed inside the operation cabinet, and OMRON CP1E is selected. The module has high integration, small size, fast CPU operation speed, ample memory, and rich range of software components. It can be expanded by plugging in expansion modules. Input, output and communication.

[0042] The human-machine interface touch screen 2 is installed on the surface of the panel of the operation cabinet, and communicates with the programmable controller PLC1. The communication mode between the touch scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com