Laser seaborne tide gauge and tide gauging method thereof

A tide measuring and laser technology, which is applied to tide measuring instruments and the field of tide measuring, can solve the problems of large changes in water level acquisition accuracy, decreased water level acquisition accuracy, fatigue of pressure metal work, etc., and achieves remarkable application effect, no maintenance, high performance Safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

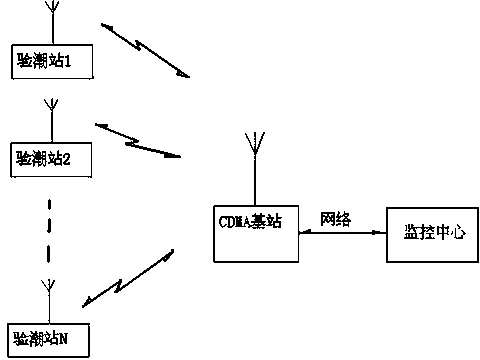

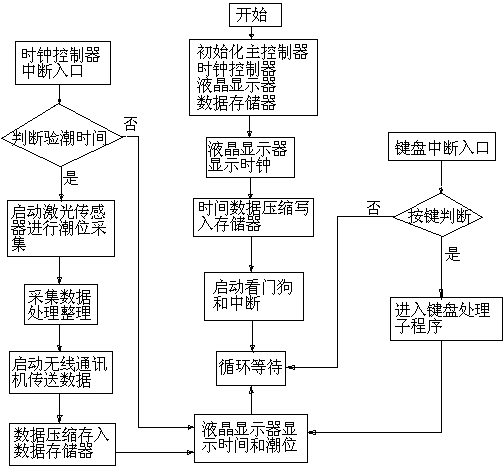

[0047] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

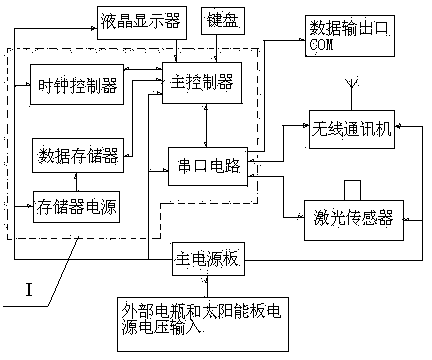

[0048] like figure 2 , Figure 4-Figure 8As shown, a laser sea tide gauge, the instrument includes a wireless communication machine, a laser sensor, a keyboard, a display, a main board circuit and a main power board; all parts except the laser sensor are arranged in a sealed case; the sealed case passes through three The sealed plugs are respectively connected to the external battery input line, wireless communication machine antenna, laser sensor 232 serial port and power line; the laser sensor is also watertight, and a waterproof socket is the data output port (COM).

[0049] figure 2 Mainboard circuit 1 shown in the dotted line frame in the middle is made up of master controller, clock controller, data memory, memory power supply, serial port circuit and periphera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com