Double-ring coaxial optical fiber turbine flow meter and test method

A technology of turbine flowmeter and coaxial optical fiber, which is applied to the volume/mass flow generated by mechanical effects, the use of optical devices to transmit sensing components, and the detection of dynamic effects of fluid flow, etc., can solve the problem of low accuracy and range of turbine flowmeters Small ratio and other issues, to achieve the effect of light weight, improved measurement accuracy, and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] This embodiment is a double-circle coaxial fiber optic turbine flowmeter and a testing method.

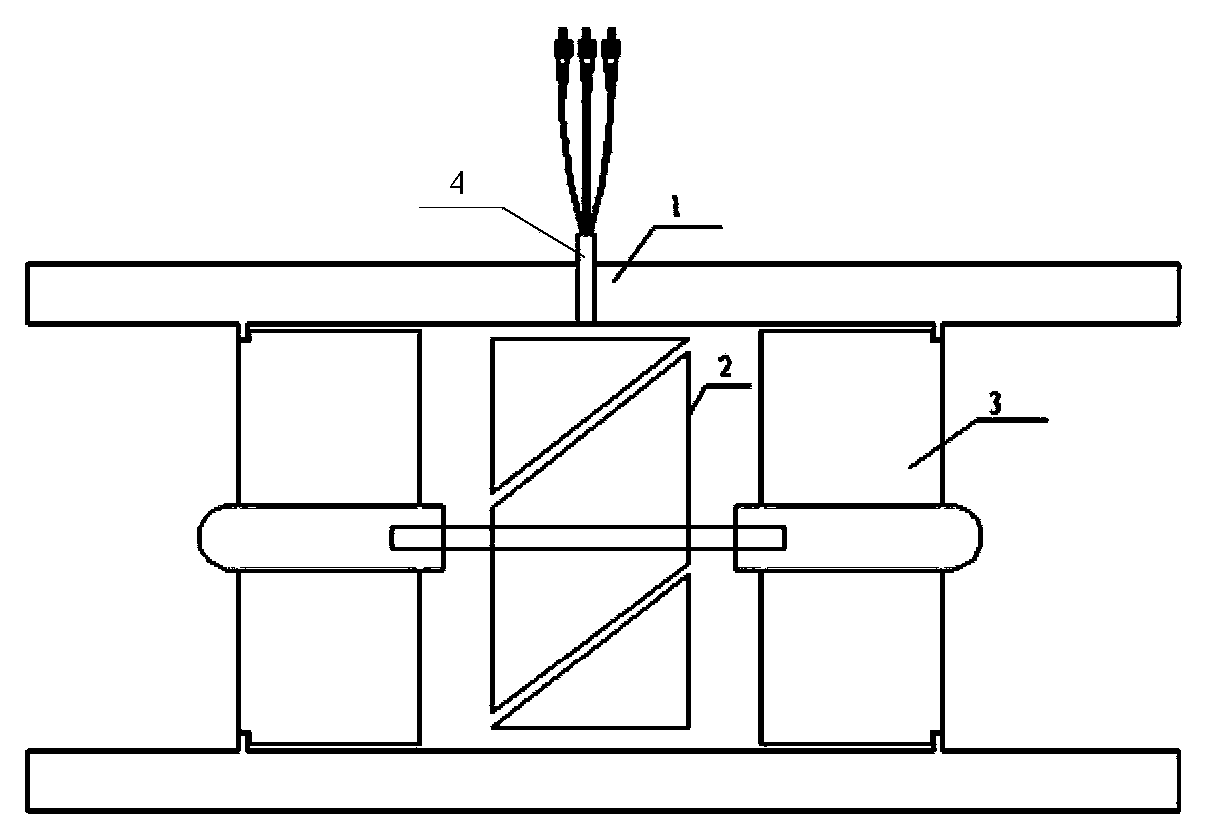

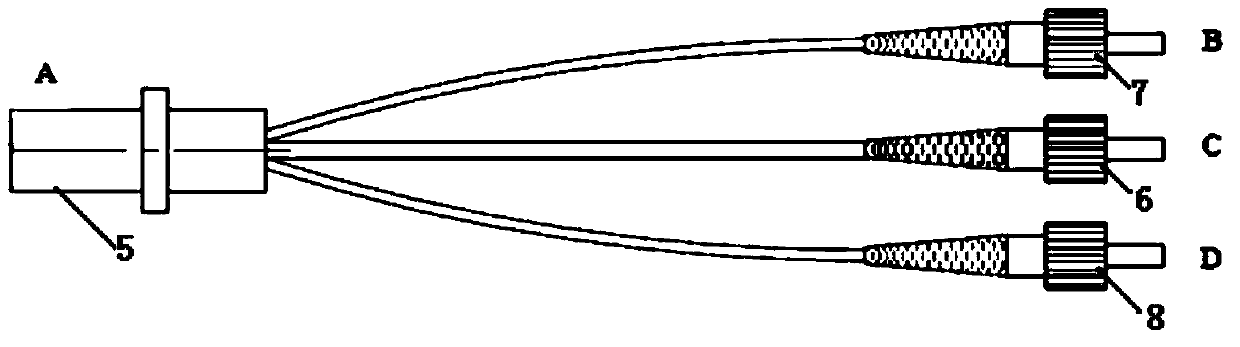

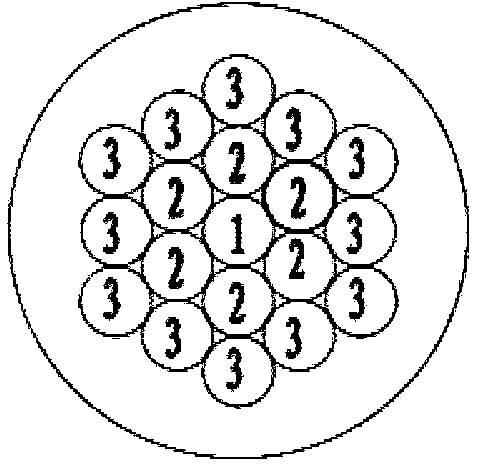

[0033] refer to Figure 1 to Figure 6 , the turbine flowmeter of double-coaxial coaxial optical fiber in this example includes a pipe housing 1, a turbine 2, a flow guide frame 3, a probe sheath 4, a double-coaxial optical fiber probe 5, a transmitting optical fiber 6, and an inner ring receiving optical fiber 7. The outer ring receives the optical fiber 8, the turbine 2 is fixedly connected with the guide frame 3, and installed in the pipe shell 1; there are screw holes on the wall of the pipe shell 1, and the double-circle coaxial optical fiber probe 5 is perpendicular to the axis of the pipe shell 1 The direction is fixedly matched with the screw hole on the wall of the pipeline shell 1, and is fixed at the middle part of the turbine 2 axial direction; the distance between the double-circle coaxial fiber optic probe 5 and the turbine blade end is 0.075mm-1.075mm; the doub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com