Production process of semi-finished rigid-flexible printed circuit boards

A printed circuit board, soft and hard combination technology, applied in the direction of assembling printed circuits with electrical components, multi-layer circuit manufacturing, etc., can solve problems such as loss of voltage, dielectric layer voids, copper surface wrinkles, etc., to increase production requirements and avoid Copper surface wrinkles and dielectric layer voids reduce work intensity and error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A production process of a soft-hard combined semi-finished printed circuit board comprises the following steps:

[0036] a. Place the lower chassis 2 under the upper chassis 1;

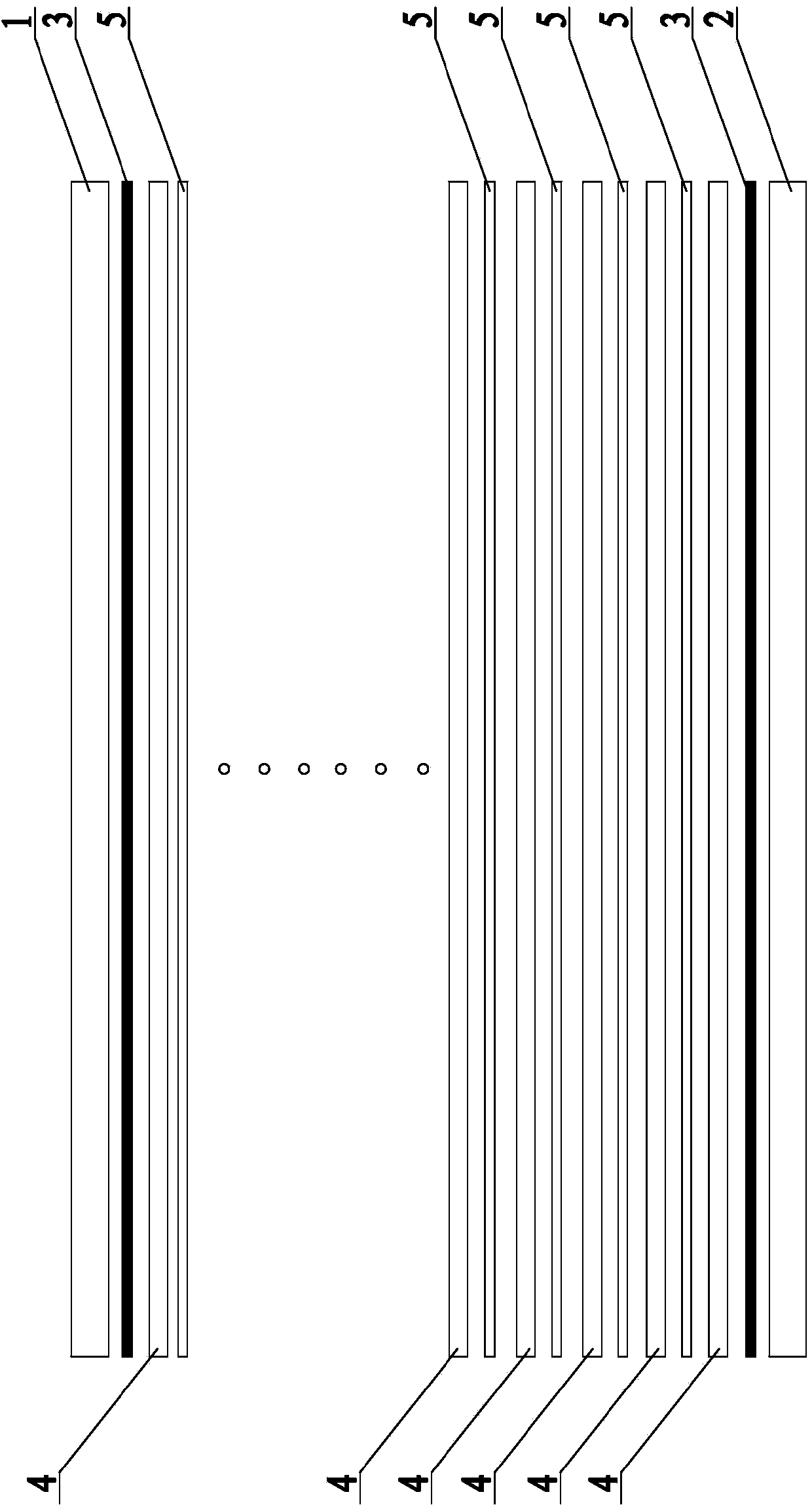

[0037] b. Place two groups of 15 layers of kraft paper between the upper chassis and the lower chassis;

[0038] c. Place 11 layers of steel plates 4 between two sets of kraft paper;

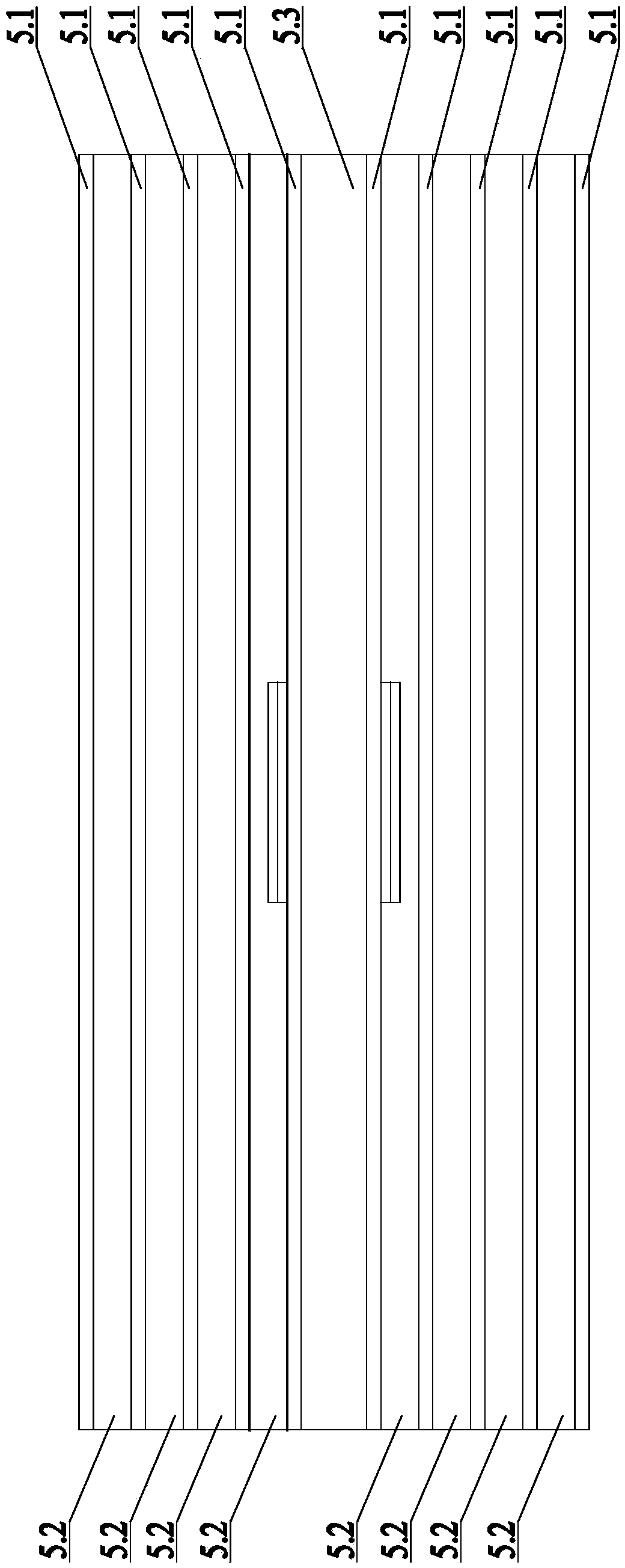

[0039] d. A layer of rigid-flex semi-finished board 5 is placed between two adjacent layers of steel plates 4 to form a rigid-flex laminate; and the semi-finished board 5 is composed of copper foil layer 5.1, semi-cured resin layer 5.2 and The flexible circuit board 5.3 is composed of several layers of copper foil layers 5.1 on the upper surface of the flexible circuit board 5.3, and a semi-cured resin layer 5.2 is provided between the two adjacent copper foil layers 5.1 above the flexible circuit board 5.3. Several copper foil layers 5.1 are provided on the lower surface of the flexible circuit board 5.3, and ...

Embodiment 2

[0051] A production process of a soft-hard combined semi-finished printed circuit board comprises the following steps:

[0052] a. Place the lower chassis 2 under the upper chassis 1;

[0053] b. Place two groups of 17-layer kraft paper 3 between the upper chassis and the lower chassis;

[0054] c. Place 13 layers of steel plates 4 between two sets of kraft paper;

[0055] d. A layer of rigid-flex semi-finished board 5 is placed between two adjacent layers of steel plates 4 to form a rigid-flex laminate; and the semi-finished board 5 is composed of copper foil layer 5.1, semi-cured resin layer 5.2 and The flexible circuit board 5.3 is composed of several layers of copper foil layers 5.1 on the upper surface of the flexible circuit board 5.3, and a semi-cured resin layer 5.2 is provided between the two adjacent copper foil layers 5.1 above the flexible circuit board 5.3. Several copper foil layers 5.1 are provided on the lower surface of the flexible circuit board 5.3, and a ...

Embodiment 3

[0067] A production process of a soft-hard combined semi-finished printed circuit board comprises the following steps:

[0068] a. Place the lower chassis 2 under the upper chassis 1;

[0069] b. Place two sets of 20 layers of kraft paper 3 between the upper chassis and the lower chassis;

[0070] c. Place 15 layers of steel plates 4 between two sets of kraft paper;

[0071] d. A layer of rigid-flex semi-finished board 5 is placed between two adjacent layers of steel plates 4 to form a rigid-flex laminate; and the semi-finished board 5 is composed of copper foil layer 5.1, semi-cured resin layer 5.2 and The flexible circuit board 5.3 is composed of several layers of copper foil layers 5.1 on the upper surface of the flexible circuit board 5.3, and a semi-cured resin layer 5.2 is provided between the two adjacent copper foil layers 5.1 above the flexible circuit board 5.3. Several copper foil layers 5.1 are provided on the lower surface of the flexible circuit board 5.3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com