Repair material for asphalt road and using method thereof

A kind of asphalt pavement repairing technology, applied to roads, roads, on-site coagulation pavements, etc., can solve the problems of slow material hardening, high maintenance costs, and easy damage again, and achieve short vehicle travel time, The effect of reducing maintenance costs and improving compressive strength and bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0040] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

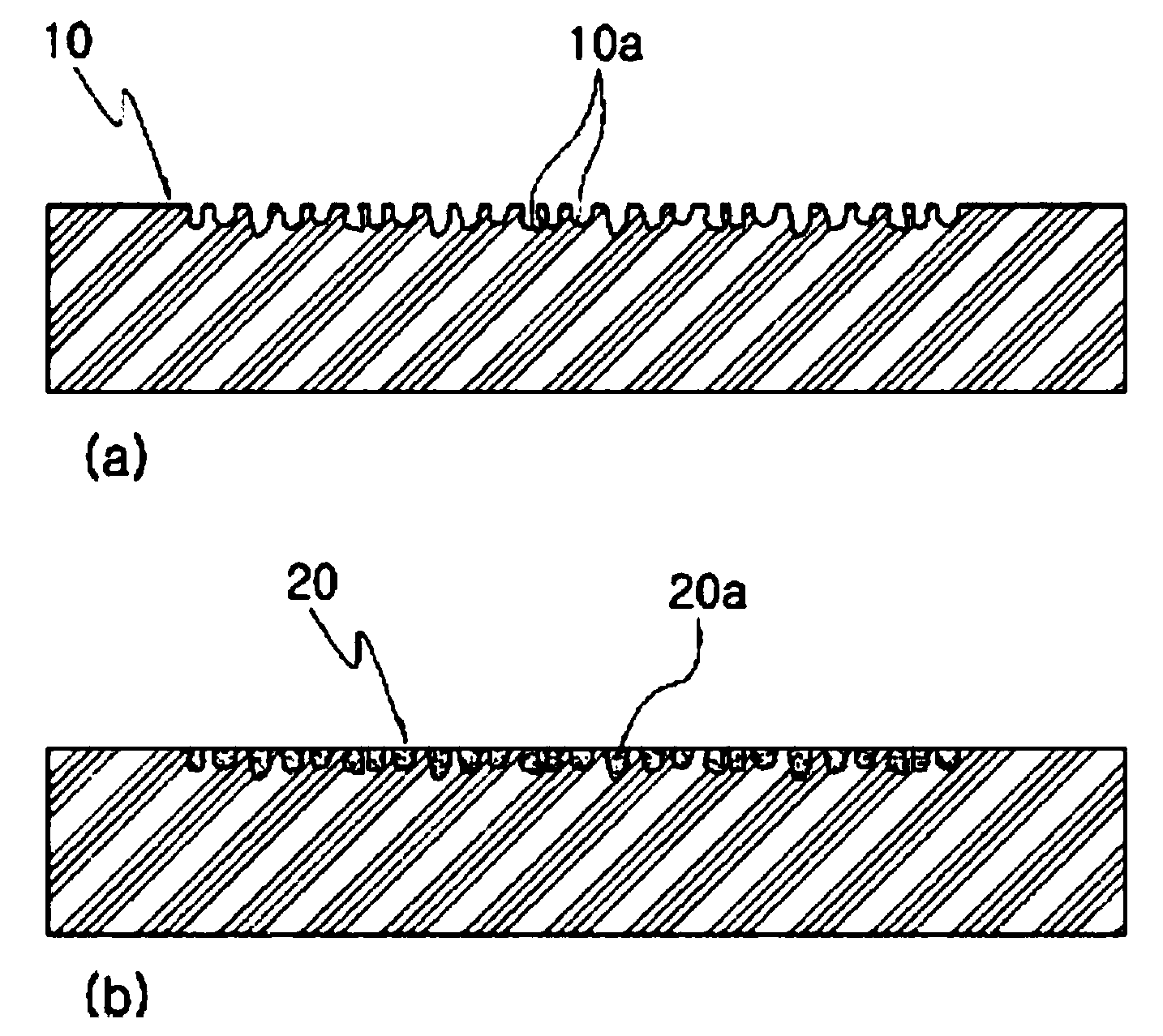

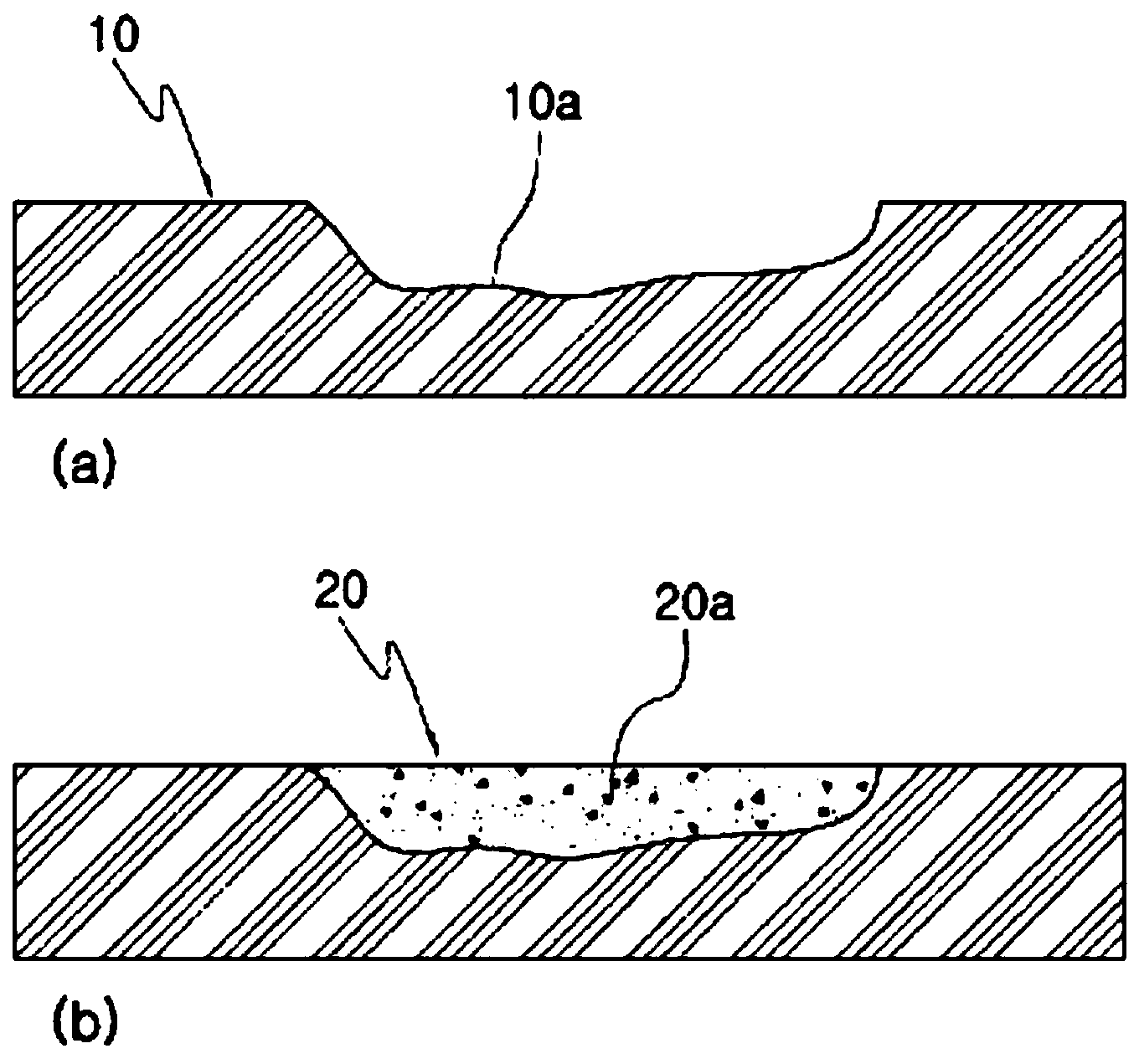

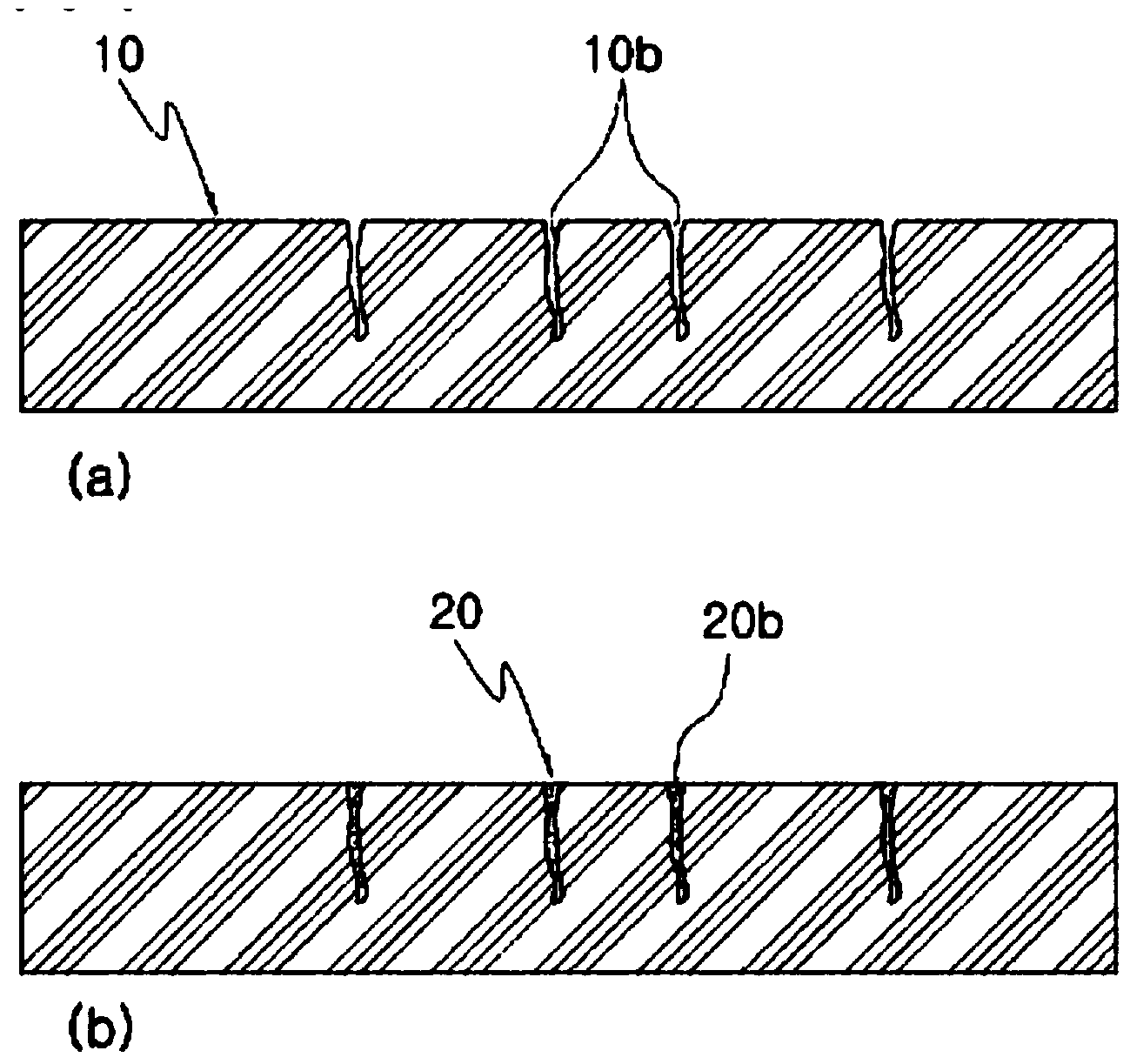

[0041] figure 1 It is a partial shedding and damaged part on the overall asphalt pavement, and a sectional view of the state after this type is repaired by the present invention.

[0042] Such as figure 1 As shown, the existing paving body (10) refers to the general asphalt pavement, and the damaged part (10a) refers to the local damage formed on the existing paving body (10) in a large range, such as Figure 5 The bumpy part of the photo.

[0043] The aggregate of the existing paving body (10) falls off partially to form a damaged part (10a), and the damaged part (10a) is subjected to rolling impact when the vehicle passes, not only the gravel combined on the road surface in an independent state will be damaged again, Moreover, the concave part of the road surface will also cause impact on the vehicle and cause damage to the vehicle. In severe cases, it will...

Embodiment

[0063] Before making quick-hardening epoxy mastic, it is first necessary to prepare a mixture of 20% quick-hardening epoxy resin, 80% silica sand with a particle diameter of 20-100 mesh, 25% quick-hardening epoxy resin, and silica sand with a particle diameter of 20-100 mesh. 75% mixture, 33% quick-hardening epoxy resin, 67% mixture of silica sand with a particle diameter of 20 to 100 meshes, and then mix according to their respective proportions to make blocks (hereinafter referred to as " patching material blocks") after hardening.

[0064] Separately take a piece of asphalt that is actually in use, and harden it after applying the material on its surface.

[0065] As a comparison material, take a piece Figure 5 The asphalt pavement material shown in actual use is the aggregate (95% by weight) formed by mixing gravel and sand used in general asphalt pavement and asphalt (5% by weight) that is heated and melted into a liquid state. ) mixed materials. The asphalt pavement ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com