Pressure vessels and apparatus for supporting them onboard of ships

A technology of pressure vessels and equipment, applied in the manufacture of pressure vessels, outer walls of vessel structures, and vessel structures, which can solve problems such as buckling and bending damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

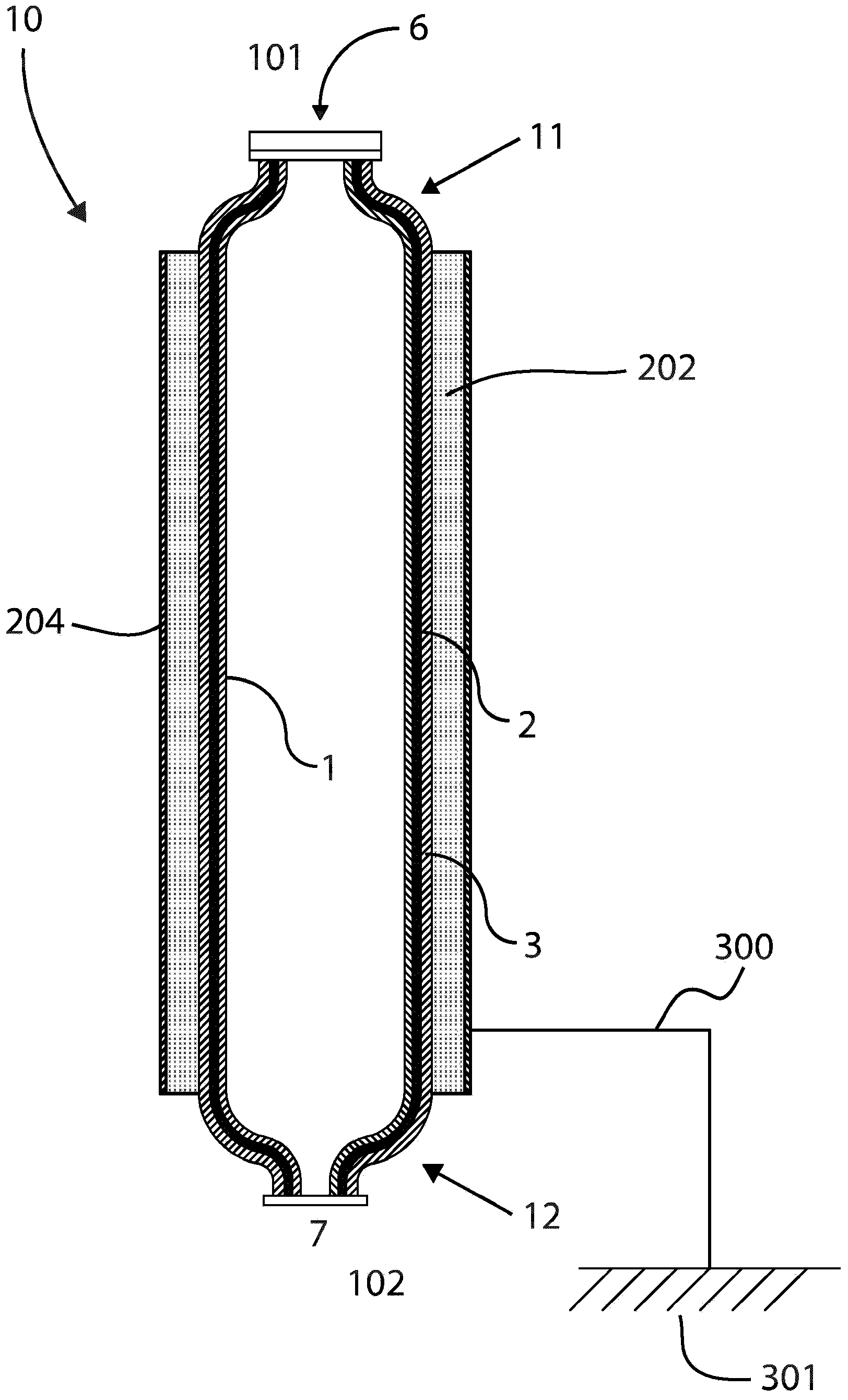

[0044] figure 1 Shown is an outer sheath, sleeve or layer 202 (in figure 1 "Type 3" multilayer CNG pressure vessel 10 in which the outer jacket, sleeve or layer is schematically represented by a cross-shaped dotted area), the insulating material is polyurethane foam in this example. A "type 3" vessel denotes a vessel having an outer structural layer made of composite, fiber reinforced material and an inner metal liner. The outer composite provides the structural strength of the vessel, while the inner liner provides an impermeable layer for containing the CNG.

[0045] Typical thermal properties of polyurethane foams are thermal conductivity in the range of 0.02 to 0.04 W / m·K at near ambient temperature.

[0046] An insulating sleeve covers the central cylindrical portion of the pressure vessel, which extends between the two end caps (first end cap 12 and second end cap 11 ). In this embodiment, both end caps 11 , 12 are equipped with their corresponding orifices eg for fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com