Method for removing metal impurities from carbon nano tube

A technology for removing carbon nanotubes and carbon nanotubes, which is applied in the field of carbon nanotube manufacturing, can solve the problems of high equipment requirements, low yield, high energy consumption, etc., and achieve the effect of simple operation, high efficiency, and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

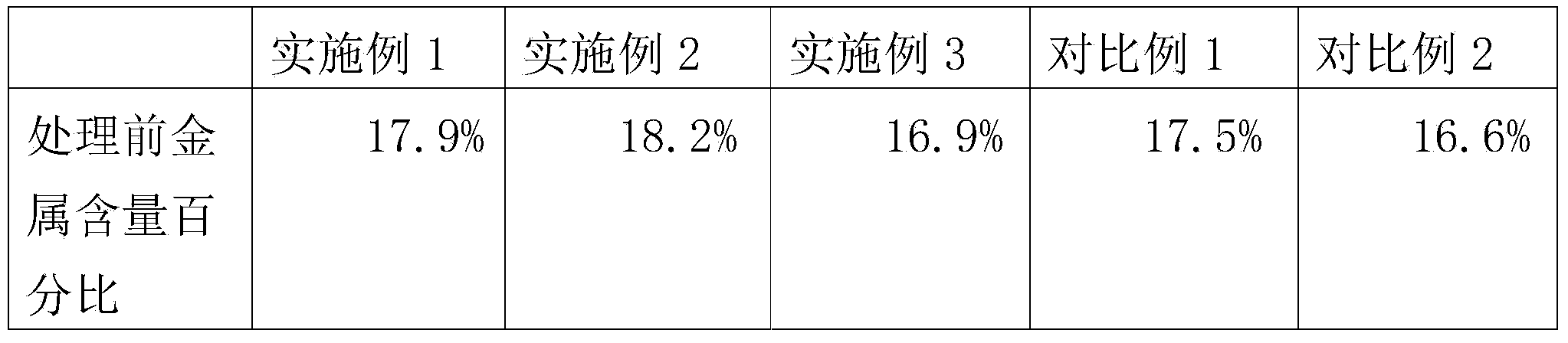

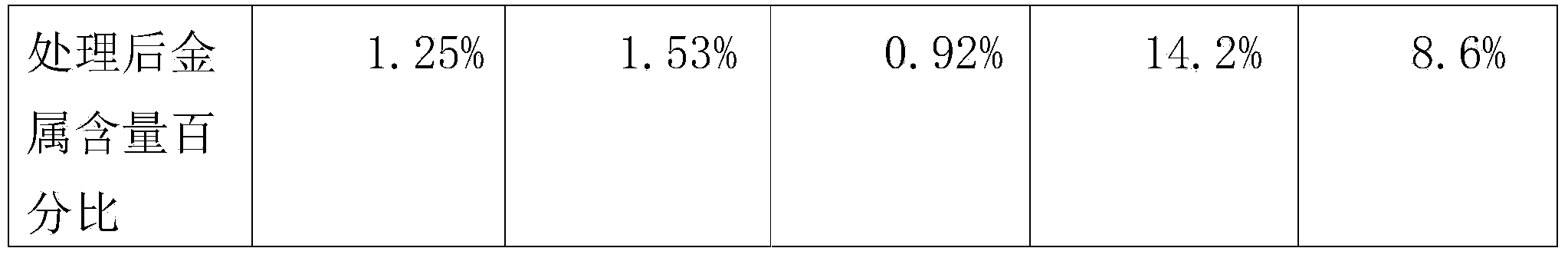

Examples

Embodiment 1

[0034] Take 500g of carbon nanotubes, add 2:1 hydrochloric acid solution (the ratio here is the volume ratio of hydrochloric acid solution to the following deionized water) to configure 10kg of carbon nanotube acid solution, stir and mix evenly, in a 20L vertical ceramic ball mill Ball mill at 300 rpm for 12 hours.

[0035] The carbon nanotube solution after ball milling was poured into a 100L stirred tank and stirred at 80° C. for 24 hours, and then the solution was poured out and the waste liquid was removed by a filter press. Put the carbon nanotube filter cake back into the stirring tank, add deionized water to stir and clean the metal ions in the solution, repeat the cleaning 2 to 3 times until the filtrate is neutral, dry the filter cake in an oven at 100°C and pulverize to obtain Purified carbon nanotubes.

Embodiment 2

[0037] Take 500g of carbon nanotubes, add 2:1 acetic acid solution (the ratio here is the volume ratio of acetic acid solution to the following deionized water) to configure 10kg of carbon nanotube acid solution, stir and mix evenly, and put it in a 20L vertical ceramic ball mill Ball mill at 300 rpm for 5 hours.

[0038] The carbon nanotube solution after ball milling was poured into a 100L stirred tank and stirred at 80° C. for 24 hours, and then the solution was poured out and the waste liquid was removed by a filter press. Put the carbon nanotube filter cake back into the stirring tank, add deionized water to stir and clean the metal ions in the solution, repeat the cleaning 2 to 3 times until the filtrate is neutral, dry the filter cake in an oven at 100°C and pulverize to obtain Purified carbon nanotubes.

Embodiment 3

[0040] Take 500g of carbon nanotubes, add 2:1 hydrochloric acid solution (the ratio here is the volume ratio of hydrochloric acid solution to the following deionized water) to configure 10kg of carbon nanotube acid solution, stir and mix evenly, and put it in a 3L horizontal ceramic sand mill Grinding at 1000rpm in the machine for 12 hours.

[0041] The sand-milled carbon nanotube solution was poured into a 100L stirred tank and stirred at 80° C. for 24 hours, and then the solution was poured out and the waste liquid was removed by a filter press. Put the carbon nanotube filter cake back into the stirring tank, add deionized water to stir and clean the metal ions in the solution, repeat the cleaning 2 to 3 times until the filtrate is neutral, dry the filter cake in an oven at 100°C and pulverize to obtain Purified carbon nanotubes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com