A kind of preparation method of high temperature-resistant adhesive used for metal and PVC connection

A high-temperature-resistant, adhesive technology, applied in adhesives, non-polymer adhesive additives, monocarboxylic acid ester copolymer adhesives, etc., can solve the problem of adhesive strength decline and achieve good adhesive strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

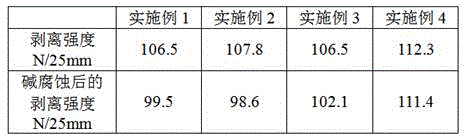

Examples

Embodiment 1

[0019] A kind of preparation method of the adhesive that is used for the metal and PVC connection of high temperature resistance, comprises the steps:

[0020] Step 1. Mix 50Kg of butyl rubber, 10Kg of acrylic resin, 5Kg of phenolic resin, 3Kg of polybutene, 4Kg of tributyl phosphate, and 10Kg of white carbon black evenly, and evenly masticate on the rubber mixer, and control the temperature of the rubber mixing Between 150°C, mixture I is obtained;

[0021] The 2nd step, polyvinyl acetate resin 5Kg is dissolved in acetone 10Kg, then antioxidant, tin protochloride, zinc oxide, mix homogeneously, obtain mixture II;

[0022] Step 3: Add mixture I and mixture II into 70Kg of ethyl acetate, stir evenly, and obtain.

[0023] The molecular weight of polybutene is between 100,000 and 200,000, the anti-aging agent is anti-aging agent MB, the phenolic resin is phenolic resin 2123, and the particle size of white carbon black is 200-400 mesh.

Embodiment 2

[0025] A kind of preparation method of the adhesive that is used for the metal and PVC connection of high temperature resistance, comprises the steps:

[0026] Step 1. Mix 70Kg of butyl rubber, 20Kg of acrylic resin, 10Kg of phenolic resin, 5Kg of polybutene, 8Kg of tributyl phosphate, and 20Kg of white carbon black evenly, and evenly masticate on the rubber mixer, and control the temperature of the rubber mixing Between 160 °C, mixture I is obtained;

[0027] The 2nd step, polyvinyl acetate resin 10Kg is dissolved in acetone 20Kg, then antioxidant, tin protochloride, zinc oxide, mix uniformly, obtain mixture II;

[0028] Step 3: Add mixture I and mixture II into 90Kg of ethyl acetate, stir evenly, and obtain.

[0029] The molecular weight of polybutene is between 100,000 and 200,000, the anti-aging agent is anti-aging agent MB, the phenolic resin is phenolic resin 2123, and the particle size of white carbon black is 200-400 mesh.

Embodiment 3

[0031] A kind of preparation method of the adhesive that is used for the metal and PVC connection of high temperature resistance, comprises the steps:

[0032] Step 1. Mix 60Kg of butyl rubber, 16Kg of acrylic resin, 6Kg of phenolic resin, 4Kg of polybutene, 6Kg of tributyl phosphate, and 16Kg of white carbon black evenly, and evenly masticate on the rubber mixer, and control the temperature of the rubber mixing Between 156 °C, mixture I is obtained;

[0033] The 2nd step, polyvinyl acetate resin 7Kg is dissolved in acetone 17Kg, then antioxidant, tin protochloride, zinc oxide, mix uniformly, obtain mixture II;

[0034] Step 3: Add mixture I and mixture II into 80Kg of ethyl acetate, and stir evenly to obtain the product.

[0035] The molecular weight of polybutene is between 100,000 and 200,000, the anti-aging agent is anti-aging agent MB, the phenolic resin is phenolic resin 2123, and the particle size of white carbon black is 200-400 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com