Method for preparing biodiesel by using ansu apricot oil

A biodiesel and apricot technology, applied in the field of biodiesel preparation technology, can solve the problems of complicated oil refining process, increased production cost, troublesome post-processing, etc., and achieve the effect of no chemical consumption, low loss and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

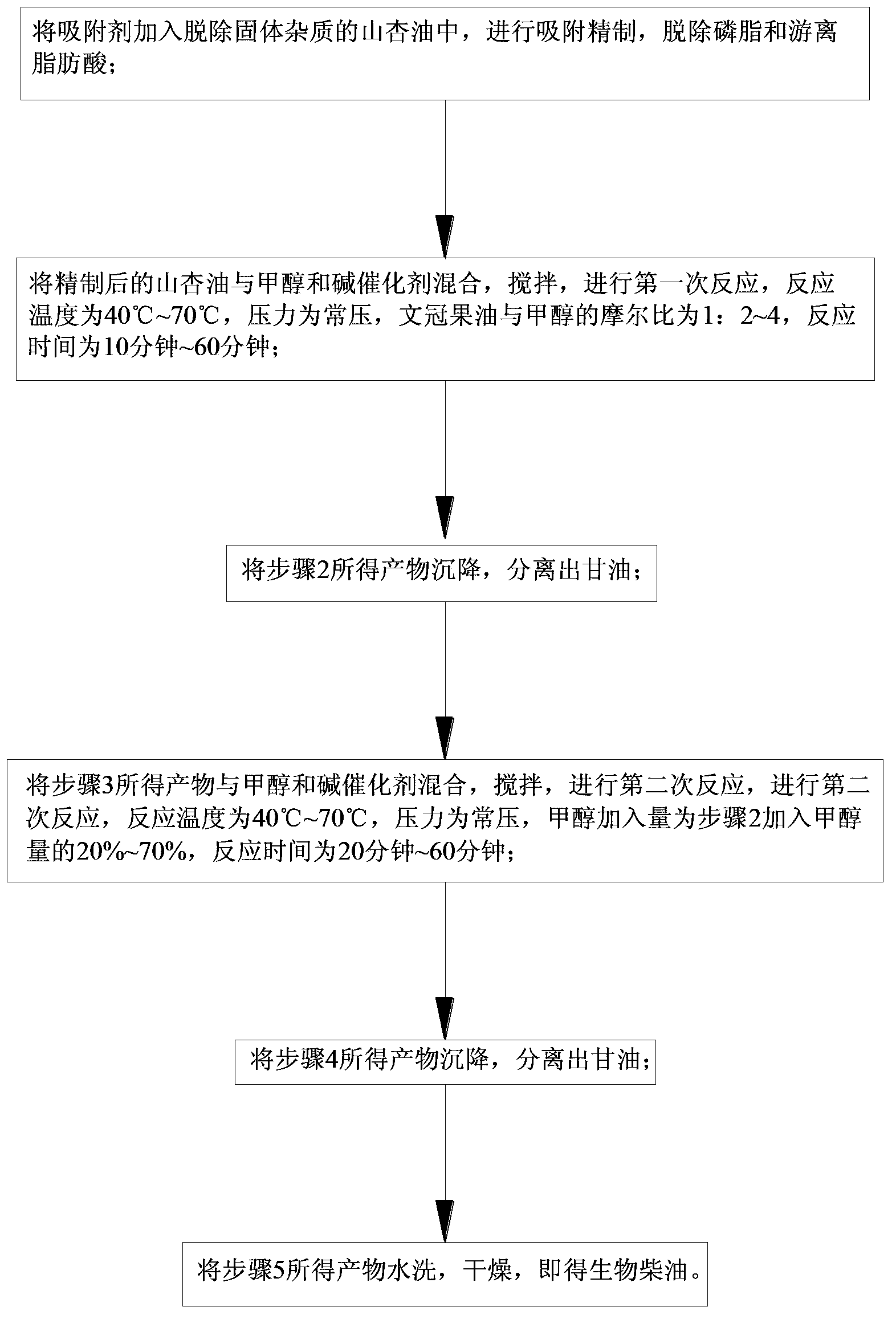

[0038] Such as figure 1 As shown, the present embodiment provides a method for preparing biodiesel from apricot oil, which is prepared by the following steps:

[0039] 1) adding the adsorbent to 100 parts by weight of the apricot oil from which solid impurities have been removed, adding 5 parts by weight of the adsorbent, performing adsorption refining, removing phospholipids and free fatty acids, and obtaining 97 parts by weight of refined apricot oil;

[0040] The adsorbent is composed of hydrophobic adsorbent, hydrophilic adsorbent and alkaline adsorbent made of silica gel or activated carbon, and the weight ratio of the three is 12:1:10. The basic adsorbent is silica gel or activated carbon loaded with NaOH, and the loading of strong alkali is 4%.

[0041] 2) Mix the refined apricot oil with methanol and 0.4 parts by weight of NaOH catalyst, stir, and carry out the first reaction. The reaction temperature is 55°C, the pressure is normal pressure, and the molar ratio of ap...

Embodiment 2

[0047] Such as figure 1 As shown, the present embodiment provides a method for preparing biodiesel from apricot oil, which is prepared by the following steps:

[0048] 1) adding the adsorbent to 100 parts by weight of the apricot oil from which solid impurities have been removed, adding 3 parts by weight of the adsorbent, performing adsorption refining, removing phospholipids and free fatty acids, and obtaining 98 parts by weight of refined apricot oil;

[0049] The adsorbent is composed of hydrophobic adsorbent, hydrophilic adsorbent and alkaline adsorbent made of silica gel or activated carbon, and the weight ratio of the three is 5:1:3. Alkaline adsorbents loaded with Na 2 CO 3 Silica gel or activated carbon with a strong base loading of 7%.

[0050] 2) Mix the refined apricot oil with methanol and 0.5 parts by weight of NaOCH 3 The catalysts are mixed, stirred, and the first reaction is carried out. The reaction temperature is 50°C, the pressure is normal pressure, the...

Embodiment 3

[0056] Such as figure 1 As shown, the present embodiment provides a method for preparing biodiesel from apricot oil, which is prepared by the following steps:

[0057] 1) adding the adsorbent to 100 parts by weight of apricot oil from which solid impurities have been removed, adding 10 parts by weight of the adsorbent, performing adsorption and refining, removing phospholipids and free fatty acids, and obtaining 97 parts by weight of refined apricot oil;

[0058] The adsorbent is composed of hydrophobic adsorbent, hydrophilic adsorbent and alkaline adsorbent made of silica gel or activated carbon, and the weight ratio of the three is 3:1:20. The alkaline adsorbent is silica gel or activated carbon loaded with KOH, and the loading of strong alkali is 10%.

[0059] 2) Mix the refined apricot oil with methanol and 0.3 parts by weight of KOH catalyst, stir, and carry out the first reaction. The reaction temperature is 65°C, the pressure is normal pressure, and the molar ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com