Correction roller expansion joint

A technology of expansion joints and rectifying rollers, which is applied to expansion compensation devices for pipelines, pipes/pipe joints/fittings, and pipelines to prevent damage/wear, etc. Short and other problems, to achieve the effect of improving thermal insulation performance, improving fire performance, and avoiding mechanical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

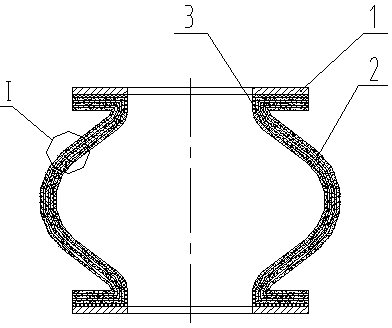

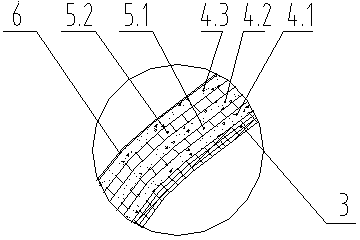

[0019] The correction roller expansion joint shown in the accompanying drawings includes a flange 1 and a drum-shaped skin 2, and the flange 1 is fixedly connected to both ends of the drum-shaped skin 2 to form a compensation structure. Drum-shaped skin 2 is a multi-layer composite structure, including steel wire mesh 3, fireproof silica gel Ⅰ4.1, ceramic cloth Ⅰ5.1, fireproof silica gel Ⅱ4.2, ceramic cloth Ⅱ5.2, fireproof Silica gel Ⅲ4.3; Fireproof silica gel Ⅰ4.1 inner side is heated and rolled on the steel wire mesh 3; fireproof silica gel Ⅰ4.1 outer side, fireproof silica gel Ⅱ4.2 inner side is melted into ceramic cloth Ⅰ5.1 by high temperature; fireproof silica gel Ⅱ4.2 outer side , The inner side of fireproof silica gel Ⅲ4.3 is melted into the ceramic cloth Ⅱ5.2 by high temperature.

[0020] The steel wire mesh 3 is a single-laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com